SHANGHAI E&V IMPORT AND EXPORT CO.,LTD |

|

Verified Suppliers

|

|

180kw 1.6m/s Copper Rod Continuous Rolling Mill with AC frequency

motor

I. major information

Mechanical design uses advanced crafts and high-quality materials,

such as roller; the appearance of the machine adopts German

design,which has higher work efficiency than other similar

products;2 high motive power frame copper rod rolling mill is

beautiful, efficient and durable.The producing capacity is 2.5ton

II. Advantage

1) good quality;

2) Low energy consumption;

3) Roll all kind of section

4)Separate motor

5) Quickly change rollers

6) Reasonable price

7)Plc control

8)high capacity

III.Main parameter

|

IV.Main component

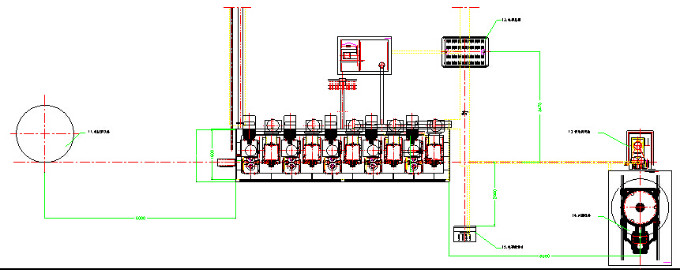

1 main rolling mill

The main rolling mill is the important part of the continuous cold

rolling mill . It includes base, frame, reducer, motor etc. Each

frame is driven by an independent motor. All the basic rolling

process is finished on the main rolling mill, and the number of the

frames is different according to different rolling size.

2 guide system

each pass has entry and exit guide, odd frame of entry guide glides

to lead in, and even frame rolls to lead in.

guide material : GCr15

guide hardness: HRC55-58

3 pay off

max load capacity :3t

4 Coiling take-up machine

This machine consists of draught gear and take-up device,

meets the characteristics of taking-up enclosure and

requirements of constant taking-up speed.

5 Oil lubrication system

oil tank capacity: 1m³

6 Emulsion system

In order to improve the surface quality of the cold rolling copper

rod, emulsion cool and lubricate the roller , copper rod and guide

device in the rolling process.

7 electrical system

The electrical system includes the power system and the controlling

system.

8 feeding and straightening device

The feeding and straightening device is in front of the main

rolling mill, and it is used to straighten the rods so that it can

feed the rod easier.

V.None scope of supply

| No. | Name |

| 1 | Infrastructure |

| 2 | Power supply system |

| 3 | Wire and cable |

| 4 | Crane |

| 5 | Emulsion pool |

| 6 | Emulsion filter |

| 7 | Emulsion pump |

| 8 | emulsion |

| 9 | Machine oil |

| 10 | pipeline |

VI.Quality Warranty Period

The seller guarantees that the equipment performance complies with

the requirements of the contract. The guarantee period of the

mechanical parts of the equipment is 12 months, calculated from the

31st day since the BL date . (The guarantee period of the electrical

parts is 6 months from the delivery date written on the contract;

wearing parts are not included in the guarantee period.)

55mm, 35mm, 25mm, 20mm, 17mm, 16mm, 14.4mm, 12.5mm, 8mm

20mm,18mm, 17mm, 8mm, 6mm, 5mm, 4mm, 3mm

Dear friends,

welcome to contact with us!