Shaanxi Rongbao Machinery and Electronics Co.,Ltd. |

|

Product Introduction

NOTICE:All the products on our website indicate the ranges we can manufacture and our production capability.

We offer cast aluminum products according to customer’s drawings or samples.

Please feel free to contact us if you have any questions or suggestions about our business.

Product Specification

| Dimension Tolerance | CT8 |

| Surface Roughness | Ra6.3-12 |

| Manufacture | OEM/ODM |

| Certificate | ISO9001:2015 |

| Standard | ASTM, DIN,JIS, EN, ISO, GB |

| Software | Pro/E,UG, Solidworks, Auto CAD, PDF |

| Material | A356, A380, aluminum alloy or according to your requirements |

| Machining | CNC turning, milling, drilling, grinding, cutting, reaming and threading |

| Service | Sand casting, die casting, low pressure die casting, Gravity casting and CNC Machining |

| Testing facility | Spectrometer, Tensile test machine, Hardness test machine, CMM (Coordinate Measuring Machine) |

| Finished | Polishing, sand blasting, heat treatment, painting, powder coating, anodizing, electroplating, Chrome plating, mirror polishing. |

| Product | All kinds of aluminum casting parts |

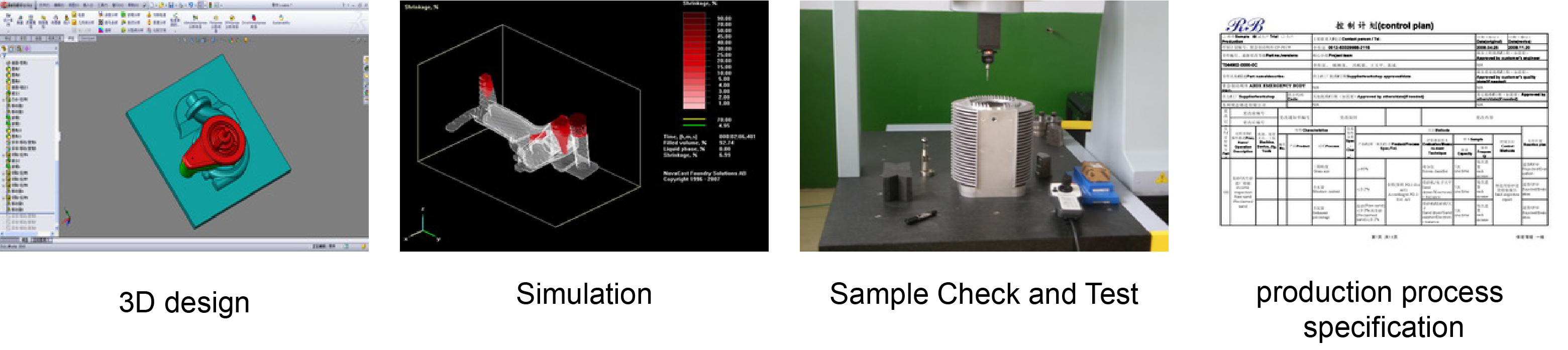

Quality Control

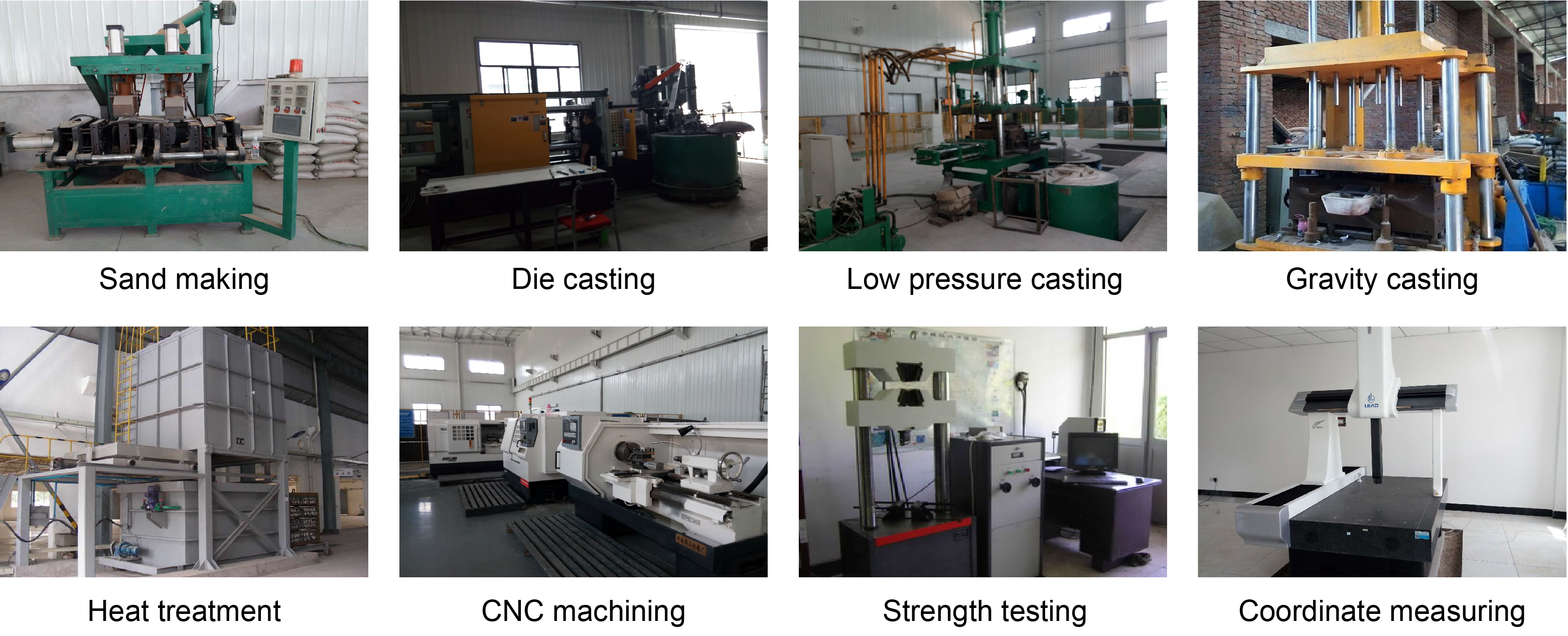

Casting Process

Packaging & Delivery

Our Customers

Office & Factory

Production Equipment

About Aluminum alloy Heat Treatment

Aluminum alloy heat treatment is to select a certain heat treatment specification, control the heating rate to a certain temperature and keep the temperature for a certain time to cool at a certain speed, change the structure of its alloy, its main purpose is to improve the mechanical properties of the alloy, enhance the corrosion resistance, improve the processing performance, and obtain the dimensional stability.

For steel with high carbon content, high hardness and low plasticity are obtained immediately after quenching. However, for aluminum alloy, the strength and hardness do not rise immediately after quenching; instead, the plasticity does not decline but rises. However, when the hardened alloy is placed for a period of time (such as 4 to 6 days and nights), its strength and hardness will be significantly improved, while its plasticity will be significantly reduced. The phenomenon that the strength and hardness of aluminum alloy increase significantly with time after quenching is called ageing. Aging can occur at room temperature, according to the natural aging, can also be higher than the room temperature at some stage in the temperature range (100 ~ 200 ℃), called artificial aging.