Cangzhou Aodong Light Industry Machinery Equipment Co., Ltd. |

|

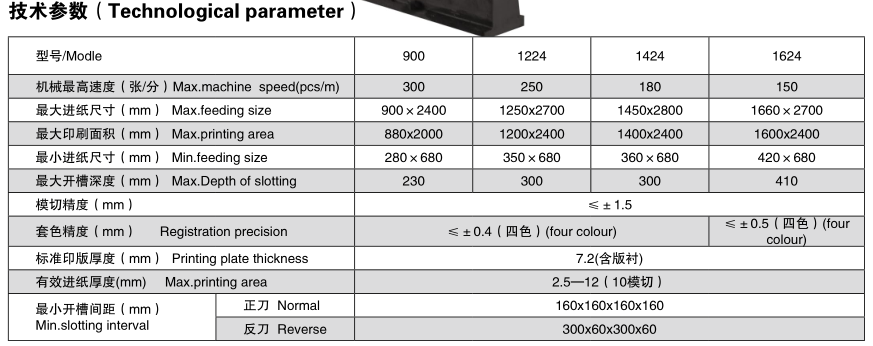

AOGS900/1224/1424/1624 automatic high-speed water-based printing slotting die-cutting machine

Uses and characteristics:

● Vacuum adsorption leading edge paper feeding system, suitable for

all kinds of tile-shaped cardboard, with stable transmission, high

speed and precision.

● The main engine, fan and phase are controlled by frequency

converter.

● transmission gear: 20GrMnTi high frequency quenching and

carburizing treatment.

● Cross roller transmission structure, without wear after long-term

use, ensures transmission accuracy.

● Keyless connection can connect the shaft with the gear to ensure

the accuracy of overprinting.

● Anti-collision device shall be adopted for cross movement of

cutter seat or box height adjustment to ensure equipment safety.

● Die-cutting speed difference compensation system, which

automatically displaces the rubber pad roller longitudinally and

transversely to prolong the service life of rubber pad.

● The soft roller is equipped with an automatic mold repairing

mechanism, which can be used after repeated repair of the Unisex

rubber, thus effectively saving the use cost of the felt sleeve.

● Mechanical spray gear oil pump circulating lubrication system,

which enhances the service life of gears and has automatic backflow

function.

● It is quick and efficient to store the common orders for slotting

knives.

Stacking department Stacker

● The paper receiving arm can be operated manually or

automatically, and a safety mechanism is provided to prevent the

paper receiving arm from falling suddenly and ensure the safety of

operators.

● The lifting of the bed is driven by a strong chain.

● the stacking height is 1600mm, 1800mm and 2000mm.

● The bed can automatically adjust the tilt height with the

stacking height of cardboard, and lift the motor with brake

function, so that the bed can keep a fixed position and will not

slide down.

● Pneumatic paper lifting mechanism, when the cardboard is stacked

to a predetermined height, the paper receiving support plate

automatically opens, and the support supports the cardboard.

● Flat wrinkle belt to prevent cardboard from slipping down.