SHANGHAI LIJIN IMP.&EXP. CO.,LTD |

|

Verified Suppliers

|

|

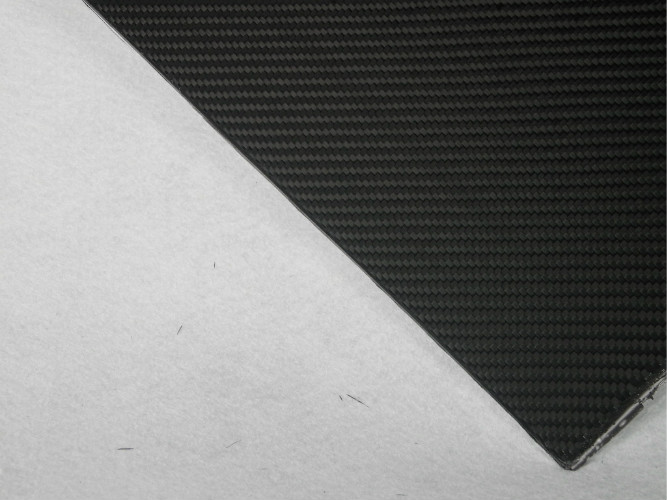

3.0mm thickness 500mm*600mm Carbon fiber Plate material and Large size .

Introduction

→ Stand for complete solution, we supply full size to pre-cut panel, as well as CNC machined parts to

your specification.

→ It can be made into pure carbon fiber or glass fiber core with carbon fiber surfaces, thickness range

from 0.3mm to 50mm, customized thicknesses and sizes are available.

→ 3k carbon fiber plate has extremely high strength, light weight, with shiny and clear appearance,

widely used for model helicopter parts and hobby market.

Specification

Color: | Black |

Shape: | as per your request |

Surface Finish: | High matte |

Patterns: | 3K twill weave |

Technology: | Laminated |

The development

In 1958, Roger Bacon created high-performance carbon fibers at the Union Carbide Parma Technical

Center, located outside of Cleveland, Ohio. Those fibers were made by heating strands of rayon until

they carbonized. This process was shown to be inefficient, as the resulting fibers had only about twenty %

carbon and had stiffness and low strength properties. In the early 1960s, a process was developed by

Dr. Akio Shindo at Agency of Industrial Science and Technology of Japan, using polyacrylonitrile (PAN)

as a raw material. This produced a carbon fiber that contained about 55 percent carbon. The high

potential strength of carbon fiber was observed in 1963 in a process inventedat the Royal Aircraft

Establishment at Farnborough, Hampshire. The process was patented by the UK Ministry of Defense

and licensed to three British companies: Rolls-Royce, already using carbon fiber, Morganite & Courtaulds. They were able to create industrial carbon

fiber production facilities within a few years, and Rolls-Royce took advantage of the new material's

properties to make a place in the American market with its RB-211 aero-engine.

Display