1.Speed /RPM

The speed at which you use your carbide bur in your rotary tool

will depend on the material you're using it on and the contour

being produced but it's safe to say you do not need to exceed

speeds of 35,000 RPM. The table below shows some approximate

speeds.

Diameter of Burr RPM

2.35mm or 3/32" 17,000 - 26,000

3mm or 1/8" 17,000 - 26,000

6mm or 1/4" 11,000 - 16,500

12mm or 1/2" 8,000 - 12,000

16mm or 5/8" 7,650 - 11,500

2.Apply only a little pressure

As with all drill bits and burrs, let the burr do the work and

apply only a little pressure otherwise the cutting edges of the

flutes will chip away or become smooth too quickly, reducing the

life of your burr.

3.Keep The Carbide Burr On The Move

When using your carbide burr try not to keep it still for too long

as this will prevent the burr from digging and jabbing into your

material causing unsightly marks and roughness.

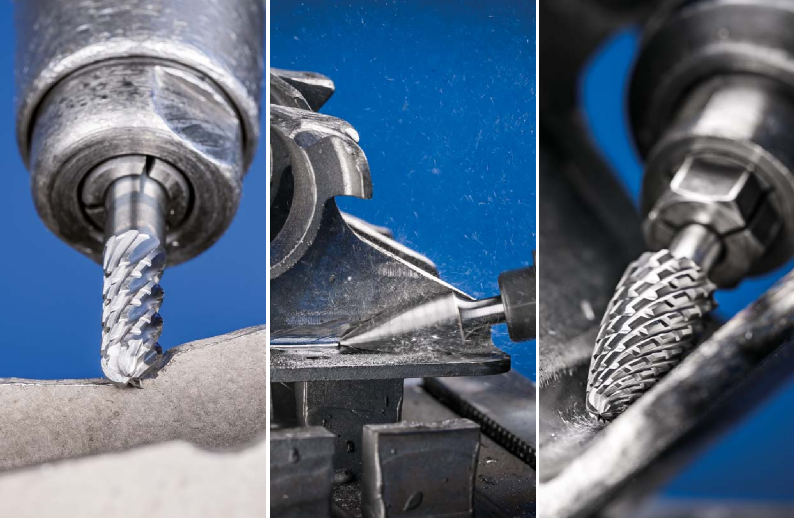

Advantage of our carbide burrs

·100% quality and brand new.

·Can Process a variety of metal and non-metal, processing hardness

would up to HRA89-92.5

·In a great part of the work, it can replace the petiole small

wheel, and no dust pollution.

·High production efficiency, the processing efficiency is several

times higher than file, nearly 10 times higher than small wheel

stalk.

·High product processing quality, high finish, can process out a

various of high-precision mold cavity.

·Long life, the durability is 10 times higher than high-speed steel

cutting tool, 200 times higher than small grinding wheel.

·Easy to use, safe and reliable, can reduce labor intensity, improve

the working environment.

·Suitable for processing these metal and non-metal, such as cast

iron, cast steel, bearing steel, high carbon steel, chrome-nickel

alloy, bronze, brass, and ceramic tile, marble, jade, bone, etc.