Supal (Changzhou) Precision Tools Co.,Ltd |

|

Verified Suppliers

|

|

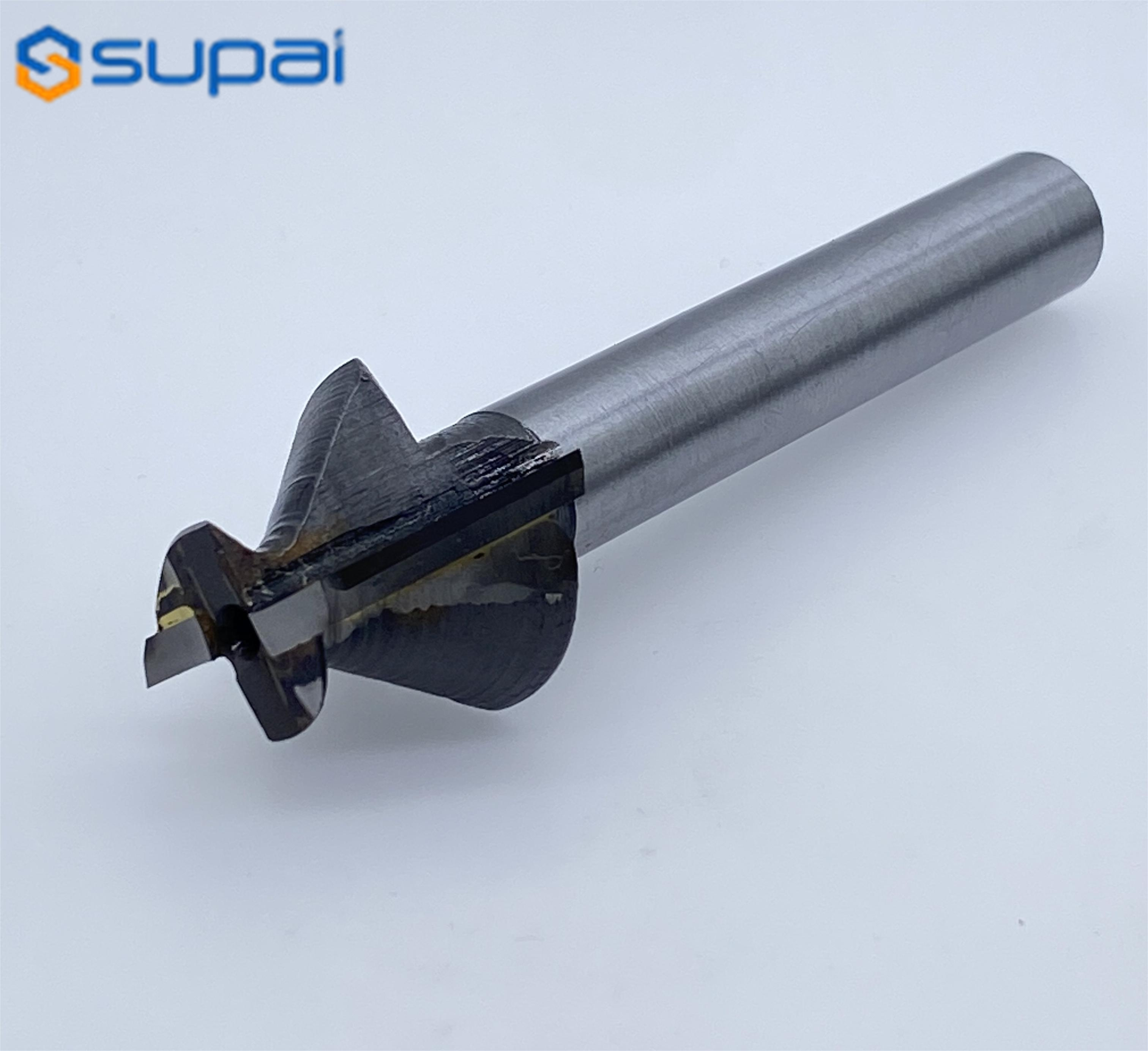

Brazed tools are commonly used in metal cutting applications due to their durability and effectiveness. They are made by brazing a carbide cutting insert onto a steel shank, creating a strong bond between the two materials. This construction provides several advantages for metal cutting operations.

Hardness and Wear Resistance: Carbide inserts used in brazed tools are extremely hard and have excellent wear resistance. They can withstand high cutting speeds and maintain their sharp cutting edges for extended periods, resulting in longer tool life.

Heat Resistance: Brazed tools can withstand high temperatures generated during metal cutting. Carbide inserts have a high melting point, allowing them to retain their hardness and cutting performance even at elevated temperatures.

Cutting Performance: The sharp cutting edges of brazed tools provide excellent cutting performance, allowing for efficient material removal and improved productivity. They can achieve high cutting speeds and produce accurate and consistent results.

Versatility: Brazed tools are suitable for a wide range of metal cutting applications, including turning, milling, drilling, and threading. They can be used with various metals, such as steel, stainless steel, cast iron, aluminum, and other non-ferrous materials.

Cost-Effectiveness: While brazed tools may have a higher initial cost compared to some other cutting tools, their longer tool life and superior performance often result in lower overall tooling costs. The extended lifespan reduces the need for frequent tool changes, leading to increased productivity and cost savings.

Ease of Use: Brazed tools are typically available in standardized shapes and sizes, making them easy to select and use. They can be easily replaced when worn out without the need for complex regrinding or reconditioning processes.

It's worth noting that while brazed tools offer many advantages, they may not be suitable for all metal cutting applications. For specialized or high-precision cutting operations, other tooling options such as indexable carbide inserts, solid carbide tools, or coated tools may be preferred. It's always important to consider the specific requirements of the metal cutting task and consult with tooling experts to determine the most suitable tooling solution.