Jiangyin Bosj Science & Technology Co., Ltd. |

|

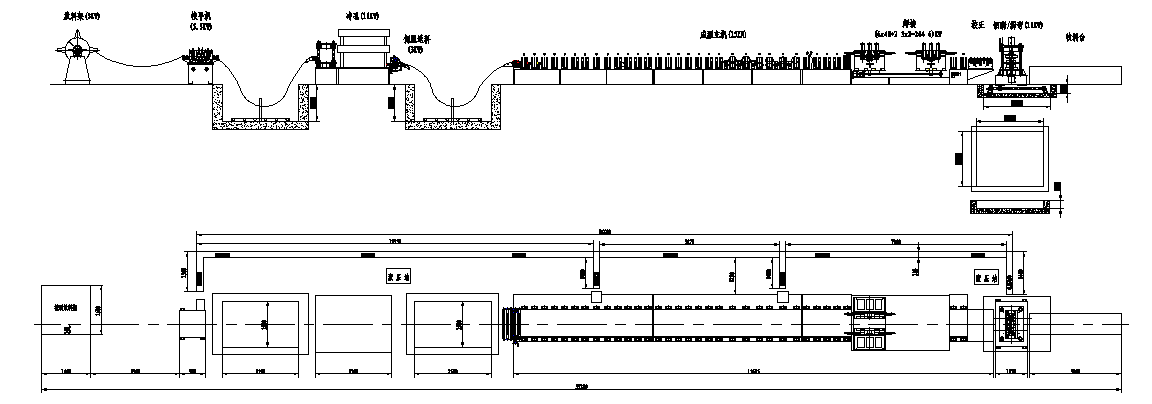

Shelf Upright Roll Forming Machine

The supermarket shelves and the stocking shelves are used widely in

modern lives. With science developing, The rack shelves are divided

for below series: The drive in rack, the medium duty shelf and the

light duty shelving and cantilever racking, Mezzanine and carton

flow rack , pallet flow storage rack..

The upright is main part of the shelves used in the supermarket and the warehouse and even the home.

Upright plays the role of supporting the whole shelves in the shelves structure. There are 80 width, 90 width, 100 width, 120 width. And with holes punching on the upright.

Rack upright roll forming machine line can finish the holes punching, the cold roll forming and cutting the upright to certain length. Rack upright cold bending roll forming machine line is used to process the upright supporting frame.

10. Machine Frame stand: welded with 36 # I-steel

Product: Shelf column, Shelf crossbeam, Shelf stay rod, Shelf plywood etc.

| Material thickness | 1.5 --3.0mm |

| Forming speed | 0-15M/min |

| Roller station | 16stations depending on the profile |

| Main power | 37KW |

| Hydraulic station | 5KW |

| PLC brand | Panasonic or Siemens Brand |

| Driving system | Gear box |

| Machine frame | Arch frame |

Advantages of Heavy Duty Pallet Racking .

1. It is suitable to be used in factories, manufactures and

warehouse

2. Size(L*W*H): 1200/1500/2000*450/600/1000*1800/2000/2500mm

3. Perfect for storing categorized products in a neat and tidy way

4. heavy-duty shelf set for warehouse shelving

5. Strong structure,special desigin for the total fucntion

6. Easy installation

7. Customization is acceptable

8. High Working Efficiency

9. Long-Service Lifespan

Determinant of Heavy Duty Pallet Racking design

1. The weight of your goods (trays, steel containers / boxes are

included)

2. The dimension of your goods together with pallets ( Length Width

Height )

3. The maximum height of your forklift and the available height of

your warehouse

4. The dimension of your forklift,if you have,please offer us,we

will consider this fact.

5. The fork direction,if you have,please offer us,we will consider

this fact.

6. The dimension of your warehouse

7. The path of the transportation

Control System | PLC Colored Touch Screen |

Main Frame | 350H STEEL |

Side Plate Thickness | 18mm |

Main Power | 15kw+4kw |

Power Supply | 380V, 3-Phase,50Hz or any |

Forming Speed | 8-12m/min |

Roll Station | 19 stands |

Shaft Diameter | 80mm |

Feeding Thickness | 1.5-2.5mm |

Cutter Standard | Cr12 |

Roller Standard | 45# Plating Cr |

Main Machine ParameterMain Machine Working Craft

| Technical Datas roll forming machine | ||

| 1 | Material width | As your regards |

| 2 | The effective width | As your regards |

| 3 | The thickness of Coil | 1.0-3.0mm or more |

| 4 | Application | Warehouse system |

| 5 | The overall dimensions | 6800mmX1500mmX1300mm |

| 6 | Total weight | 5 Tons |

| 7 | Main Power | 5.5 KW |

| 8 | Uncoiler | Manual Uncoiler |

| 9 | Inner diameter | 508--610mm |

| 10 | Outer diameter | 1200mm |

| 11 | Loading weight | 3T |

| 12 | Forming speed | 5-10m/min |

| 13 | Forming steps | 12 stations or more |

| 14 | Bracket | welded with 36 # I-steel |

| 15 | Material of Shafts | 45# steel with rough finished and then refined finished |

| 16 | Diameter of the Roll | 76mm |

| 17 | Material of Rolls | high quality 45#steel coated with hard chromium 0.05 mm |

18 | Processing Technology | rough processing ---refined processing--Hard Chromium Plating. |

| 19 | Material of Rack | complete welded structure of A3 steel plate 16mm thickness |

20 | Transmission | Transmitted by the chain-bracket/ Gearbox T180 |

| 21 | Material of Chain | 45#steel with heat treatment of HRC45-50° |

| 22 | Holders under chain for lubricant | By the machine |

| 23 | Material of cutting blade | Cr12 with quenched treatment 60-62 |

| 24 | Cutting system | Hydraulic cutting |

| 25 | Voltage | 380V/50HZ/3phase |

BOSJ offer you the full range warehouse system products,BOSJ has a

profesional engineering and production team to work with you.