TOBO STEEL GROUP CHINA |

|

Verified Suppliers

|

|

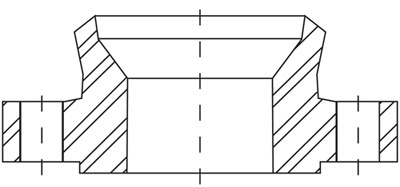

An expander flange, abbreviated as EXPF, is similar to a weld neck flange but with the hub expanding to a larger size (one or two sizes). If you have limited space or just need to connect to a larger pipe size, it provides a convenient way for equipment, pumps and valves. It can replace the use of a flange and reducer. Pressure ratings and dimensions are in accordance with ANSI/ASME B16.5. This flange has a raised face.

STANDARD SPECIFICATIONS OF EXPANDER FLANGE

Type:Expander Flange

Size:½” (15 NB) to 48″ (1200NB)

Class:150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

DIN:DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

BS:BS4504 , BS4504, BS1560, BS10

In Form:SORF, WNRF, BLRF, SWRF, LAP Joint, Threaded, Reducing, Spectacle, etc

Standard:ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, EN1092, UNI 2277/2278, DIN, JIS, SABS1123, GOST-12820

Coating/Surface Treatment:Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized

Connection Type:Ring Type Joint, Lap-Joint Face, Raised Face, Flat Face, Large Male-Female, Small Male-Female, Large, Tongue & Groove, Small Tongue & Groove

Flange Face Type:Flat Face (FF), Raise Face (RF), Ring Joint (RJT)

Dimensions:ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Packing:No Fumigate or Fumigate Plywood/Wood Pallet or Case

Usage/Applications:Oil Field, Offshore, Water System, Shipbuilding, Natural Gas, Electric Power, Pipe Projects etc.

MATERIALS, STANDARDS, & GRADES OF EXPANDER FLANGE

Stainless Steel Expander Flange:ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L

Duplex Steel Expander Flange:ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Super Duplex Expander Flange:ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Nickel Alloys Expander Flange:ASTM SB564, SB160, SB472, SB162 – Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020)

Copper Alloys Expander Flange:ASTM SB 61 , SB62 , SB151 , SB152 – UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200

Alloys Expander Flange:ALLOY 20, ALLOY C, ALLOY C276, ALLOY B2

Low Temperature Steel Expander Flange:ASTM A350 LF2, LF3, LF6

High Yield Expander Flange:ASTM A694 F42, F52, F60, F65, F70

Carbon Steel Expander Flange:ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706

Alloy Steel Expander Flange:ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Dimentions

Expander Flanges are used in marine and offshore engineering.

Prevent any damage.

During transportation items are tagged, packed in plastic bags and

closed in carton boxes or seaworthy wooden cases.

plywood case,pallet and according to customer's requirment

Q1. Are you trade company or factory?

A: We are trading company in shanghai, but we have five branch factories which can supply the best quality pipes, tubes, fittings flanges and related accessories. Welcome to visit us.