VIIPLUS INTERNATIONAL |

|

Engine connecting rod bushes made from high tin aluminum alloys offer superior performance and durability in demanding automotive applications. These bushes, also known as big-end bearings or crankpin bearings, play a crucial role in the efficient and reliable operation of internal combustion engines.

High tin aluminum alloys, typically containing a significant percentage of tin (Sn) along with aluminum (Al) and other alloying elements, are chosen for their excellent wear resistance, fatigue strength, and thermal conductivity. These properties ensure that the connecting rod bushes can withstand the high temperatures, pressures, and dynamic loads generated by the reciprocating motion of the piston and connecting rod.

In addition to their material properties, the precision manufacturing process ensures that the connecting rod bushes fit precisely into the connecting rod and crankshaft journals. This precise fit reduces friction and wear, improving engine efficiency and durability.

The use of high tin aluminum alloys in engine connecting rod bushes has become increasingly common in modern automotive engines, particularly in high-performance and racing applications. These bushes are able to meet the demanding requirements of these engines, providing superior reliability and durability under extreme operating conditions.

Overall, engine connecting rod bushes made from high tin aluminum alloys are an essential component for ensuring the smooth and efficient operation of internal combustion engines. They provide superior wear resistance, fatigue strength, and thermal conductivity, making them a reliable choice for a wide range of automotive applications.

The development trend of sliding bearing materials was pointed out, which was to develop the unleaded bearing materials and speed up research and development in new materials and technologies.

Internal combustion engine connecting rod bush bushing, bimetallic tin aluminum alloy bearing, JF-20 high tin aluminum axle bush bearing

JF-20 443946 aluminium base bearing alloy |

The inner diameter

39 (mm)

Outer diameter

44 (mm)

The thickness of the

46 (mm)

Aluminum bushing, steel bronze bimetal bushes, composite bush has a combination of high strength, load-bearing capacity, and the advantages of good wear resistance. Particularly suited to medium-speed and low-speed high-contained set and so on.

High tin aluminum bearing, is based on steel matrix, the surface of roller AISn20Cu material

products. This product has secondary fatigue strength and bearing capacity, good corrosion

resistance, good sliding properties, etc. This product is used for medium and small power of internal

combustion engine bearing shell machine collar axis, the train

engine bearings, air, is replacing babbitt novel products.

| Maximum dynamic load | 90P N/mm² | The highest temperature(°C) | Grease lubrication | 150°C | |

| Maximum linear velocity | Grease lubrication | —— | Fluid lubrication | 250°C | |

| High PV value | —— | Match the diameter of the axle | hardness HRC | ≥270 | |

| The coefficient of friction(μ) | —— | roughness Ra | 0.16~0.63 | ||

| Maximum linear velocity | Fluid lubrication | 15 | Alloy layer hardness | 30~40 | |

| High PV value | 8 | Coefficient of thermal conductivity | 47W/mk | ||

| The coefficient of friction(μ) | 0.04~0.12 | Linear expansion coefficient (axial) | 18×10-6/K | ||

Normal Thickness | Tolerances of Series B (non-machinable) | Tolerances of Series C (non-machinable) |

| 1.0 | -0.025 | +0.25 +0.15 |

| 2.0 | -0.030 | +0.25 +0.15 |

| 2.5 | -0.035 | +0.25 +0.15 |

| 3.0 | -0.040 | +0.30 +0.15 |

| 3.5 | -0.045 | +0.30 +0.15 |

| 3.5 | -0.050 | +0.30 +0.15 |

Engineering machinery: end of popular institutions supporting wheel

shaft sleeve, towing axle sleeve, tensioning shaft sleeve; Auto

industry: the balance shaft lining, steel pin bushing, steering

knuckle main shaft sleeve shaw, connecting rod bushings, valve

rocker arm shaft sleeve, CAM shaft collar, differential bushings,

transmission shaft sleeve, the internal combustion engine spindle

watts, thrust washers, And plunger pump side piece, such as a piece

of gear pump side.

| Size | Customizable |

| Certification | ISO9001, TS16949 |

| Processing methods | Cold-extrusion |

| Operating temperature | 150℃(Grease lubrication),250℃(Oil lubrication) |

| Material | Steel+AlSn20Cu |

| Surface treatment | Copper Plating/Tin Plating |

| Typical Application | High speed, heavy load engine main shaft, and air compressor, cooling machine, etc. |

| Bushing | Nominal dimensions | Finished dimensions | ||||||

| Steel backed aluminum bimetal bushing | Bushing inner diameter | Housing inner diameter | Housing inner diameter H7 | Axle diameter f7, e7 | Housing inner diameter H7 after assembly | Bushing outer diameter | Bushing length | Thickness (alloy thickness 0.3 mm) |

| Steel backed aluminum bimetal bushing | 10 | 12 | 12 +0.018 0 | 10 f7 -0.013 -0.028 | 10 +0.015 0 | 12 +0.068 +0.043 | 5. 10. 15 |

1.0 0 -0.015 |

| Steel backed aluminum bimetal bushing | 12 | 14 | 14 +0.018 0 | 12 f7 -0.016 -0.034 | 12 +0.018 0 | 14 +0.068 +0.043 | 5. 15. 20 | |

| Steel backed aluminum bimetal bushing | 15 | 17 | 17 +0.018 0 | 15 -0.016 -0.034 | 15 +0.018 0 | 17 +0.068 +0.043 | 10. 15. 20 | |

| Steel backed aluminum bimetal bushing | 18 | 20 | 20 +0.021 0 | 18 -0.016 -0.034 | 18 +0.018 0 | 20 +0.086 +0.056 | 10. 20. 30 | |

| Steel backed aluminum bimetal bushing | 20 | 23 | 23 +0.021 0 | 20 f7 -0.020 -0.041 | 20 +0.021 0 | 23 +0.086 +0.056 | 10. 20. 30 |

1.5 0 -0.015 |

| Steel backed aluminum bimetal bushing | 22 | 25 | 25 +0.021 0 | 22 -0.020 -0.041 | 22 +0.021 0 | 25 +0.086 +0.056 | 15. 25. 40 | |

| Steel backed aluminum bimetal bushing | 25 | 28 | 28 +0.021 0 | 25 -0.020 -0.041 | 25 +0.021 0 | 28 +0.086 +0.056 | 15. 30. 40 | |

| Steel backed aluminum bimetal bushing | 28 | 32 | 32 +0.025 0 | 28 -0.020 -0.041 | 28 +0.021 0 | 32 +0.115 +0.075 | 15. 30. 50 |

2.0 0 -0.02 |

| Steel backed aluminum bimetal bushing | 30 | 34 | 34 +0.025 0 | 30 -0.020 -0.041 | 30 +0.021 0 | 34 +0.115 +0.075 | 15. 30. 50 | |

| Steel backed aluminum bimetal bushing | 32 | 36 | 36 +0.025 0 | 32 f7 -0.025 -0.050 | 32 +0.025 0 | 36 +0.115 +0.075 | 20. 40. 50 | |

| Steel backed aluminum bimetal bushing | 35 | 39 | 39 +0.025 0 | 35 -0.025 -0.050 | 35 +0.025 0 | 39 +0.115 +0.075 | 20. 40. 60 | |

| Steel backed aluminum bimetal bushing | 38 | 42 | 42 +0.025 0 | 38 -0.025 -0.050 | 38 +0.025 0 | 42 +0.115 +0.075 | 20. 40. 60 | |

| Steel backed aluminum bimetal bushing | 40 | 44 | 44 +0.025 0 | 40 -0.025 -0.050 | 40 +0.025 0 | 44 +0.115 +0.075 | 20. 40. 60 | |

| Steel backed aluminum bimetal bushing | 42 | 46 | 46 +0.025 0 | 42 -0.025 -0.050 | 42 +0.025 0 | 46 +0.115 +0.075 | 20. 40. 60 | |

| Steel backed aluminum bimetal bushing | 45 | 50 | 50 +0.025 0 | 45 -0.025 -0.050 | 45 +0.025 0 | 50 +0.115 +0.075 | 30. 50. 80 |

2.5 0 -0.025 |

| Steel backed aluminum bimetal bushing | 48 | 53 | 53 +0.030 0 | 48 -0.025 -0.050 | 48 +0.025 0 | 53 +0.145 +0.095 | 30. 50. 80 | |

| Steel backed aluminum bimetal bushing | 50 | 55 | 55 +0.030 0 | 50 -0.025 -0.050 | 50 +0.025 0 | 55 +0.145 +0.095 | 30. 50. 80 | |

| Steel backed aluminum bimetal bushing | 52 | 57 | 57 +0.030 0 | 52 e7 -0.060 -0.090 | 52 +0.030 0 | 57 +0.145 +0.095 | 30. 60. 80 | |

| Steel backed aluminum bimetal bushing | 55 | 60 | 60 +0.030 0 | 55 -0.060 -0.090 | 55 +0.030 0 | 60 +0.145 +0.095 | 30. 60. 90 | |

| Steel backed aluminum bimetal bushing | 60 | 65 | 65 +0.030 0 | 60 -0.060 -0.090 | 60 +0.030 0 | 65 +0.145 +0.095 | 30. 60. 90 | |

| Steel backed aluminum bimetal bushing | 65 | 70 | 70 +0.030 0 | 65 -0.060 -0.090 | 65 +0.030 0 | 70 +0.145 +0.095 | 30. 70. 100 | |

| Steel backed aluminum bimetal bushing | 70 | 76 | 76 +0.030 0 | 70 -0.060 -0.090 | 70 +0.030 0 | 76 +0.160 +0.095 | 40. 70. 100 |

3.0 0 -0.03 |

| Steel backed aluminum bimetal bushing | 75 | 81 | 81 +0.035 0 | 75 -0.060 -0.090 | 75 +0.030 0 | 81 +0.165 +0.100 | 40. 80. 100 | |

| Steel backed aluminum bimetal bushing | 80 | 86 | 86 +0.035 0 | 80 -0.060 -0.090 | 80 +0.030 0 | 86 +0.165 +0.100 | 40. 80. 100 | |

| Steel backed aluminum bimetal bushing | 85 | 91 | 91 +0.035 0 | 85 e7 -0.072 -0.107 | 85 +0.035 0 | 91 +0.165 +0.100 | 40. 90. 100 | |

| Steel backed aluminum bimetal bushing | 90 | 96 | 96 +0.035 0 | 90 -0.072 -0.107 | 90 +0.035 0 | 96 +0.165 +0.100 | 50. 100 | |

| Steel backed aluminum bimetal bushing | 100 | 106 | 106 +0.035 0 | 100 -0.072 -0.107 | 100 +0.035 0 | 106 +0.180 +0.115 | 50. 100 | |

| Steel backed aluminum bimetal bushing | 110 | 117 | 117 +0.035 0 | 110 -0.072 -0.107 | 110 +0.035 0 | 117 +0.180 +0.115 | 60. 100 |

3.5 0 -0.035 |

| Steel backed aluminum bimetal bushing | 120 | 127 | 127 +0.040 0 | 120 -0.072 -0.107 | 120 +0.035 0 | 127 +0.185 +0.120 | 60. 100 | |

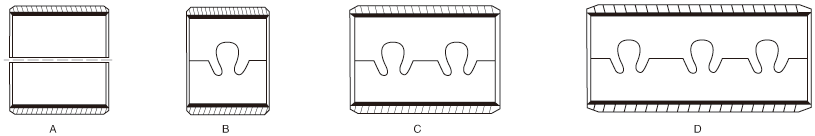

This is a made-to-order product that we do not keep inventory for. Additional construction work for oil grooves and lubrication channels may be required depending on the actual conditions of use.