VIIPLUS INTERNATIONAL |

|

The first cost-competitive alternative to C93200 (SAE660) bronze

bearings.

Owing to the high quality and variability, our oilless bushes are widely used in the automobile, engineering, electrical and consumer goods industries. Quality is the number one characteristic, which our business partners expect from our sliding bearings products. We endeavor to offer more – customer care, technical service, and guidance – which our business partners receive together with high-quality materials for injection molding.

It breaks through the limit of general bearing whose lubrication depends on an oil film.

So it is suitable for high temperature, heavy-duty, anti-corrosion, or where oil is hard to be introduced.

It′s performance doubles both on hardness and wear-friction. It is now widely applied in successive Casting Machines,

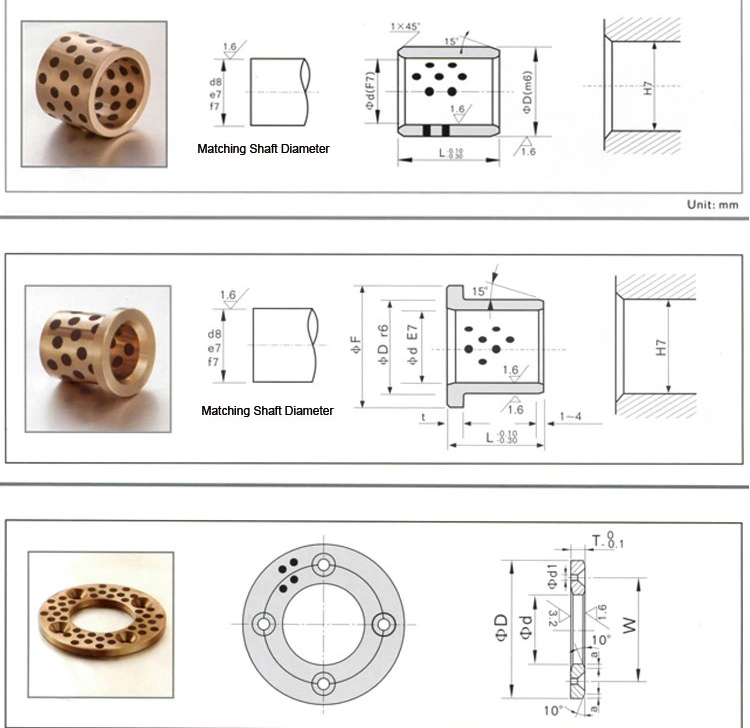

Sleeve Bearing

Flange Bearing (Double Flange bushing also)

Thrust Bearing (also called a Thrust Washer)

Each type is available as a Plain Bearing, Grooved (Oil or Grease),

and/or Graphite Plugged Bearing.

STANDARD BRONZE ALLOYS*C93200, C86300 Bearing made from Cast

Bronze and Solid Lubricant Inserts, graphite inserts for

temperatures above 250°C, Self-Lubricating / Oil

Impregnated, Graphite Plugged Bushing provides

self-lubrication that can operate in high-temperature environments. High-Temperature Dry-Running Oilless Flange Sleeve Bearing Bushing. Cost-Effective

Solution, Aak a better quote for your part number. Sleeve;

Flanged Available

available high-quality bronze alloys. Embedded in this structure are solid lubricant

inserts or plugs, providing continuous lubrication for low friction and wear rates and long service life.

1. Sliding layer with running-in-film

2. Solid lubricant inserts

3. Bronze

Bronze Bearing forms made to order: cylindrical bushes, flanged

bushes, thrust washers, sliding plates, customized bearing designs

Corrosion resistance depends largely on the lubricant, bronze

bearing, and mating surface materials.

Graphite plugs bronze bearings should never be used where

electrolytic corrosion can occur, such as high humidity atmospheres or submerged equipment. In this case, PTFE-based plugs are recommended

Oilless Flange Sleeve Bearing Bushing High hardness impregnated brass solid lubrication bearing is improved upon

Oilless Flange Sleeve Bearing Bushing by further enhance the

hardness of high hardness brass, giving rise to higher load-bearing capacity and better wear-resistant property. The products are widely used in continuous casting

rolling machines, mining equipment, engineering equipment,

injection-molding machines, etc. Because of its high hardness, it's

difficult to machining and finish, it's recommended only for really

high load applications.

| Basic material | CuZn25A16Fe3Mn3 | Dynamic load | 120N/mm² |

| Base hardness | HB210~275 | Friction Coef | <0.16 |

| Temperature Max | 300℃ | Speed limit | dry 0.4m/s oil 5m/s |

Oilless Flange Sleeve Bearing Bushing, JDB material is made of

strong cast bronze based metal with special solid lubricants

embedded. The base metal withstands high load and the solid

lubricants provide for self-lubrication. Oilless Flange Sleeve

Bearing Bushing shows excellent performance without pre-lubrication under conditions of extreme high/lower

temperature with low speed. This material provides a maintenance-free bearing solution, particularly for high load, intermittent oscillating motion.

Oilless Flange Sleeve Bearing Bushing can be applied under dry, high temperature, high pressure, corrosive, water, or other chemical environments when no oil can

be introduced.

Oilless Flange Sleeve Bearing Bushing is widely be used in

automotive product line, water engineering, dam gate, plastic

industries, successive casting machines, steel rollers in

metallurgy industry, mineral machines, ship turbo generators,

hydraulic turbines, and injection molding machines.

| Material | Brass | Bronze | Bronze | Bronze | Bronze |

| CuZn25Al6Mn4Fe3 | CuSn5Pb5Zn5 | CuAl10Ni5Fe5 | CuSn10Pb10 | CuSn12 | |

| Yield Point N/mm2 | >450 | >90 | >260 | >150 | >100 |

| Tensile strength N/mm2 | >750 | >200 | >600 | >260 | >210 |

| Elongation % | >12 | >15 | >10 | >8 | >8 |

| Hardness HB | >210 | >70 | >150 | >95 | >75 |

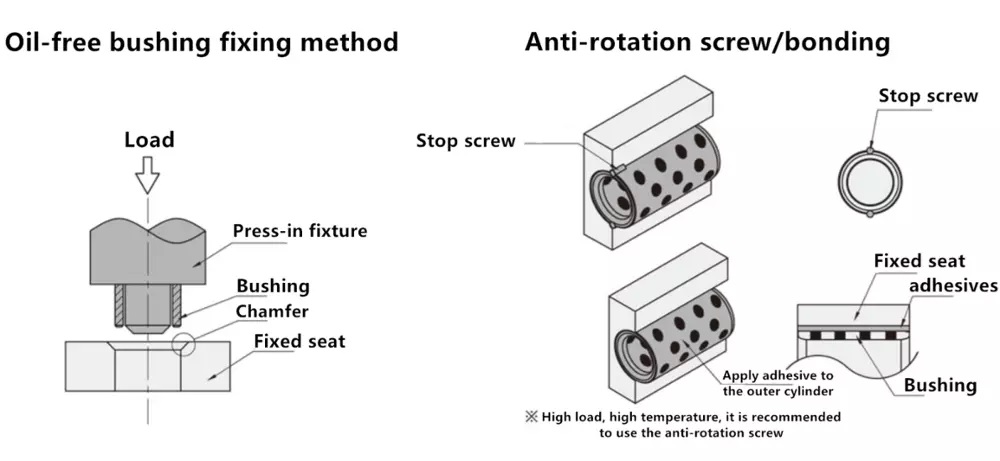

When pressing the oil-free bushing, use a vise or punch to press it in quietly. In order to facilitate the press-in, it is recommended to chamfer the end of the inner diameter of the fixed seat, apply a small amount of lubricating oil to the inner diameter of the fixed seat and the outer diameter of the bushing.

Note that when the oil-free bushing is prevented from falling off and turning, it is recommended to use the following methods depending on the conditions of use and the environment.

The life of oilless bushings depends on the amount of wear. The

calculation of wear amount is very different due to surface

pressure, sliding speed, movement pattern, lubrication conditions,

the surface roughness of the matching shaft, and other conditions.

From the viewpoint that the wear amount is proportional to the load

and sliding distance, the following formula is usually used to

calculate the wear amount. Please consider it as the standard for

selection.

Estimate wear(mm)W=K*1×p×v×T

Wear ratio(k):mm/(N/mm2·m/s·Hr)

Design surface pressure(p):N/mm2

Sliding speed(v):m/s

Friction time(T):Hr-hr