VIIPLUS INTERNATIONAL |

|

Anti-Wear Low Friction Coefficient Bronze Sleeve Bushings are

precision-engineered components designed to provide exceptional

wear resistance and low friction in demanding applications. Made of

high-quality bronze material, these bushings are renowned for their

durability, reliability, and long service life.

The low friction coefficient of bronze sleeve bushings

significantly reduces energy loss and heat generation during

operation, making them ideal for high-speed and high-load

applications. The material's excellent wear resistance ensures that

the bushings maintain their performance and dimensional stability

over extended periods of use.

The sleeve design of these bushings allows for easy installation

and replacement, minimizing downtime and maintenance costs.

Additionally, the bronze material is corrosion-resistant, further

enhancing the bushings' durability and lifespan.

These bushings are suitable for a wide range of industries and

applications, including but not limited to:

Automotive and aerospace industries: Bronze sleeve bushings are

commonly used in precision components such as engines,

transmissions, and landing gear systems, where low friction and

wear resistance are crucial.

Machine tools and industrial equipment: These bushings are ideal

for use in machine tools, conveyor systems, and other industrial

equipment where smooth operation and reliability are essential.

Energy and mining industries: Bronze sleeve bushings are suitable

for applications in power plants, oil and gas extraction equipment,

and mining machinery, where they can handle harsh environments and

heavy loads.

In summary, Anti-Wear Low Friction Coefficient Bronze Sleeve

Bushings offer a combination of exceptional wear resistance, low

friction, and durability that makes them a reliable choice for

demanding applications across various industries.

Bronze Ptfe Steel Backed bushings are used in the rear-wheel suspension of this electric scooter.

Best value Bushing Scooter – Great deals on Bushing Scooter ...

Wholesale Electric Motor Bushing Bearing Steel Bushing

Buy cheap bushing for scooter — low prices, shipping online, Cheap

bushing for scooter – a catalog of goods at low prices and with fast delivery. And a wide range of quality bushing products from china.

Scooter Bushing

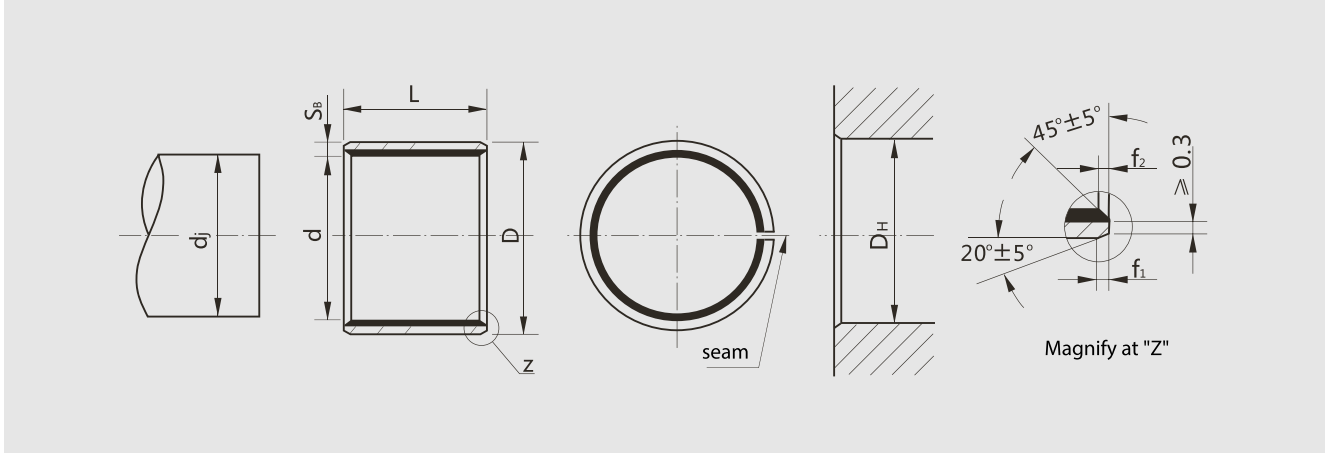

1. PTFE with Pb 0.01~0.03mm

2. Porous bronze 0.2~0.3mm

3. Stainless steel backing 0.7~2.3mm

| Specific load capacity (static) | ≤ 250 [ N/mm² ] | |

| Specific load capacity (dynamic) | ≤ 140 N/mm² at low speeds | |

| Specific load capacity(rotating oscillating) | ≤60N/m㎡ | |

| Friction value | 0.08 to 0.2 µ(dry)0.02 to 0.08µ(hydrodynamic) | |

| Temperature | -200 to +280 [ °C ] | |

| Max. dry running Pv (Short-term operation) | 3.6N/m㎡﹡m/s | |

| Max. dry running Pv (Continuous operation) | 1.8N/m㎡﹡m/s | |

| Max. speed (dry running) | 2m/s | |

| Max. speed (Hydrodynamic operation) | >2m/s | |

Low friction coefficient, good anti-wear, good anti-corrosion

Performs well in mid-acid and strong alkaline condition

Standard cylindrical bushings, flanged bushings, thrust washers and

strips are availabe

Special designs are produced at short notice

Lead free type is also available

Material | Stainless Steel Base+Bronze Powder +PTFE |

Typical Application | the corrosion resistant part in dyeing machinery and ocean industry, etc. |

Max Static Load | 250N/mm² |

Max Dynamic Load | 140N/mm² |

Max Oscoillation Load | 60N/mm² |

Max Line Speed | Dry 2.5m/s, Oil > 5m/s |

PV Value Limit | Dry 1.8N/mm².m/s,Oil 3.6N/mm².m/s |

Friction Coefficient | Dry 0.08~0.20, Oil 0.02~0.12 |

Mating Axis | Hardness >220, Roughness 0.4~1.25 |

Working Temperature | -200~+280℃ |

Thermal Conductivity | 40W/mk |

Coefficient Of Linear Expansion | 11×10-6/K |

1,We are produce high quality and low price good wear resistance sliding bush

supplier

2,Our sliding bush passed the ISO TS 16949 .

3,Under the guidance of Pursuit of the excellence & keep

improving.

4,We will do our best to provide the quality products and professional sevices.