VIIPLUS INTERNATIONAL |

|

Pillow Blocks Oilless Bronze Graphite Plugged Bushings are high-performance components designed to provide smooth and reliable operation in various industrial applications.

Constructed from bronze, these bushings exhibit excellent strength and durability, making them suitable for high-load and high-speed applications. The oilless design eliminates the need for lubrication, reducing maintenance requirements and operational costs.

The graphite-plugged feature of these bushings ensures effective lubrication and wear resistance, extending the service life of the bushings. This also results in reduced friction and improved efficiency of the rotating system.

Pillow Blocks Oilless Bronze Graphite Plugged Bushings are commonly used in machinery, pumps, motors, and other rotating equipment. Their precision-fitted design ensures accurate alignment and stability, reducing vibration and noise.

With their robust construction and high-quality materials, these bushings offer reliable performance in even the most challenging industrial environments. Whether used in indoor or outdoor applications, they provide a long-lasting and cost-effective solution for smooth and efficient rotation.

VIIPLUS specialized in research and development, production and sale of self-lubricating bearings. The main Rigid Split Pillow Blocks products are metallic polymer composite bearings, bimetallic composite bearings, bronze coated bearings, self-lubricating monometallic bearings and other bearings.

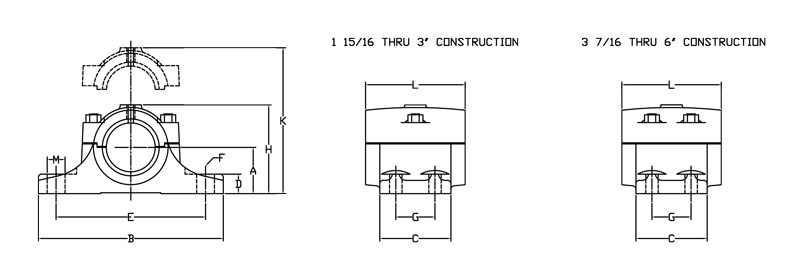

Split pillow block bearing housing and/or bearing is split into two pieces and bolted together, facilitating easier maintenance or bearing replacement for worn or damaged bearings or shafts.

Rigid Split Pillow Blocks Service requirements with side loading or angular pressures require ball bearings. These bearings allow you to accommodate loads within 30 ° on each side of the grease groove. They have all the features of regular split bearings, as well as the rigid style. These bearings are only available with a bronze coating material.

The Four-Bolt Base is made of Cast Iron with 2 or 4 bolt mounting locations.

Cast iron belongs to the family of materials whose main component is iron, with important trace amounts of carbon and silicon. Cast iron is a natural composite material whose properties are determined by its microstructure — stable and metastable phases formed during solidification or subsequent heat treatment. The main microstructural components of cast irons are chemical and morphological forms taken by carbon, and a continuous metal matrix in which carbon and / or carbide are dispersed.

| Shaft Size | Part Number | Wt. | A | B | C | D | E | F-Dia. Bolt | G | H | K | L | M | Pipe Tap | ||||

| Bronze | ||||||||||||||||||

|

| 10 | 1 3⁄4 | 8 1⁄4 | 3 1⁄2 | 7⁄8 | 6 1⁄2 | 1⁄2 | 1 3⁄4 | 3 7⁄16 | 4 7⁄16 | 4 | 3⁄4 | 1⁄4 | ||||

|

| 13 | 1 7⁄8 | 8 1⁄2 | 3 1⁄2 | 1 | 6 3⁄4 | 1⁄2 | 1 3⁄4 | 3 3⁄4 | 4 7⁄8 | 4 1⁄2 | 3⁄4 | 1⁄4 | ||||

|

| 18 | 2 1⁄8 | 10 1⁄4 | 4 | 1 1⁄8 | 8 | 5⁄8 | 2 | 4 3⁄16 | 5 5⁄16 | 5 | 1 | 1⁄4 | ||||

|

| 21 | 2 1⁄4 | 10 1⁄2 | 4 1⁄4 | 1 1⁄4 | 8 1⁄4 | 5⁄8 | 2 1⁄4 | 4 1⁄2 | 5 7⁄8 | 5 1⁄2 | 1 | 1⁄4 | ||||

|

| 26 | 2 1⁄2 | 11 | 4 1⁄2 | 1 3⁄8 | 8 3⁄4 | 5⁄8 | 2 1⁄2 | 4 7⁄8 | 6 3⁄4 | 6 | 1 | 3⁄8 |

| Shaft Size | Part Number | Wt. | A | B | C | D | E | F-Dia. Bolt | G | H | K | L | M | Pipe Tap | ||||

| Bronze | ||||||||||||||||||

|

| 43 | 3 1⁄4 | 13 | 5 | 1 3⁄8 | 10 1⁄2 | 3⁄4 | 2 3⁄4 | 6 1⁄4 | 8 1⁄8 | 7 | 1 1⁄4 | 1⁄2 | ||||

|

| 62 | 3 1⁄2 | 14 3⁄4 | 5 1⁄2 | 1 1⁄2 | 12 | 3⁄4 | 3 | 6 13⁄16 | 9 3⁄8 | 8 | 1 3⁄8 | 1⁄2 | ||||

|

| 86 | 4 1⁄8 | 16 1⁄2 | 6 1⁄4 | 1 3⁄4 | 13 1⁄2 | 7⁄8 | 3 1⁄2 | 7 7⁄8 | 10 3⁄8 | 9 | 1 1⁄2 | 1⁄2 | ||||

|

| 116 | 4 1⁄2 | 18 | 7 | 1 7⁄8 | 15 | 7⁄8 | 4 | 8 9⁄16 | 11 1⁄4 | 10 | 1 5⁄8 | 1⁄2 | ||||

|

| 166 | 5 | 19 1⁄4 | 7 3⁄4 | 2 | 15 3⁄4 | 1 | 4 1⁄2 | 9 3⁄8 | 12 1⁄4 | 11 | 1 3⁄4 | 1⁄2 | ||||

|

| 198 | 5 1⁄2 | 20 1⁄2 | 8 1⁄2 | 2 1⁄8 | 16 1⁄2 | 1 1⁄8 | 5 | 10 1⁄4 | 13 3⁄4 | 12 | 1 7⁄8 | 1⁄2 |

heavy industrial operations:

·Power Generation (Coal)

·Mining/Aggregate/Cement

·Metal MillsPulp & Paper/Sawmills/Forestry/Water Treatment

·Food Processing

·Warehousing

·Movable Bridges/Structures

·Industrial Fans/Blowers

·Fixing screw - The bearings fixed with a fixing screw are fixed to the shaft by a fixing screw, located on an inner ring, that is, the bearings have fixing screws to secure the inner ring to a shaft.

·The locking collar bearings have a locknut to secure the inner ring

to the shaft.

·No bearing fixing method does not have provisions for fixing an

axle.

This procedure is for the most common adjustment screw or collar for the shaft locking device, using a fixed and expansion unit, but the general guidelines apply to all bearing installations.

1. Check and clean the Shaft

First, check your shaft to make sure it is clean, round,

straight, free of burrs and nicks and that it is not undersized or

oversized, according to the manufacturer's specifications. Use fine

sandpaper or shiny tape to clean the tree of any rust. Then use a

light coat of oil to remove debris.

2. Put the bearings on the shaft

Use a hammer and a block of wood or a soft steel tube on the inner

ring when placing the bearing on the shaft if the bearing needs to

be knocked in place. Do NOT hit or exert pressure on the housing or

seals.

3. Lightly screw the housing to the mounting structure

Position the shaft in position by lightly screwing the housing to

the mounting structure. Bridge the slots in the housing mounting

bolts with heavy washers or heavy spring washers. This can help

prevent loosening.

4. Establish the final mounting position

Before fixing the bolts, establish your final mounting position by

aligning the bearings by hand or with a rubber mallet.

5. Securely screw the housing to the mounting structure

After proper alignment of the bearing, securely secure both units

to the mounting structure.

6. Make sure the shaft can move axially

WE ARE A PROFESSIONAL

SELF-LUBRICATING BEARING MANUFACTURER & SUPPLIER