VIIPLUS INTERNATIONAL |

|

Introducing our range of dry corrosion-resistant P10 polymer plain bearings, sourced directly from China and designed for superior performance in demanding environments. These bearings are crafted from a special P10 polymer material that offers exceptional wear resistance and low friction, ensuring smooth and reliable operation even under heavy loads and high-speed conditions.

The P10 polymer is specifically formulated to resist corrosion, making it ideal for applications where exposure to moisture, chemicals, or other corrosive elements is a concern. This material's inherent corrosion resistance ensures longer bearing life and reduced downtime due to maintenance or replacement.

In addition to its corrosion-resistant properties, the P10 polymer also exhibits low friction characteristics. This results in less energy loss during operation, leading to improved efficiency and reduced operating costs. The bearings' smooth surface finish further enhances their friction-reducing capabilities, ensuring a consistent and reliable performance over time.

Our P10 polymer plain bearings are also known for their high wear resistance. This material is able to withstand heavy loads and high-speed operation without significant wear or degradation. This makes them ideal for applications where durability and longevity are paramount.

As a Chinese supplier, we are able to offer competitive pricing and fast delivery times for our P10 polymer plain bearings. We have a wide range of sizes and configurations available to meet your specific needs, and our team of experts is available to provide assistance and support throughout the purchasing process.

In summary, our dry corrosion-resistant P10 polymer plain bearings are an excellent choice for applications requiring superior wear resistance, low friction, and corrosion protection. With their reliable performance and competitive pricing, these bearings are sure to meet your demanding requirements.

P10 is a dry friction bearing, with good wear resistance, the result is hard and reliable because of the lead, suitable for dry and not long-term maintenance of the field, P10 dry friction bearing can add grease but its role is general, it is not recommended

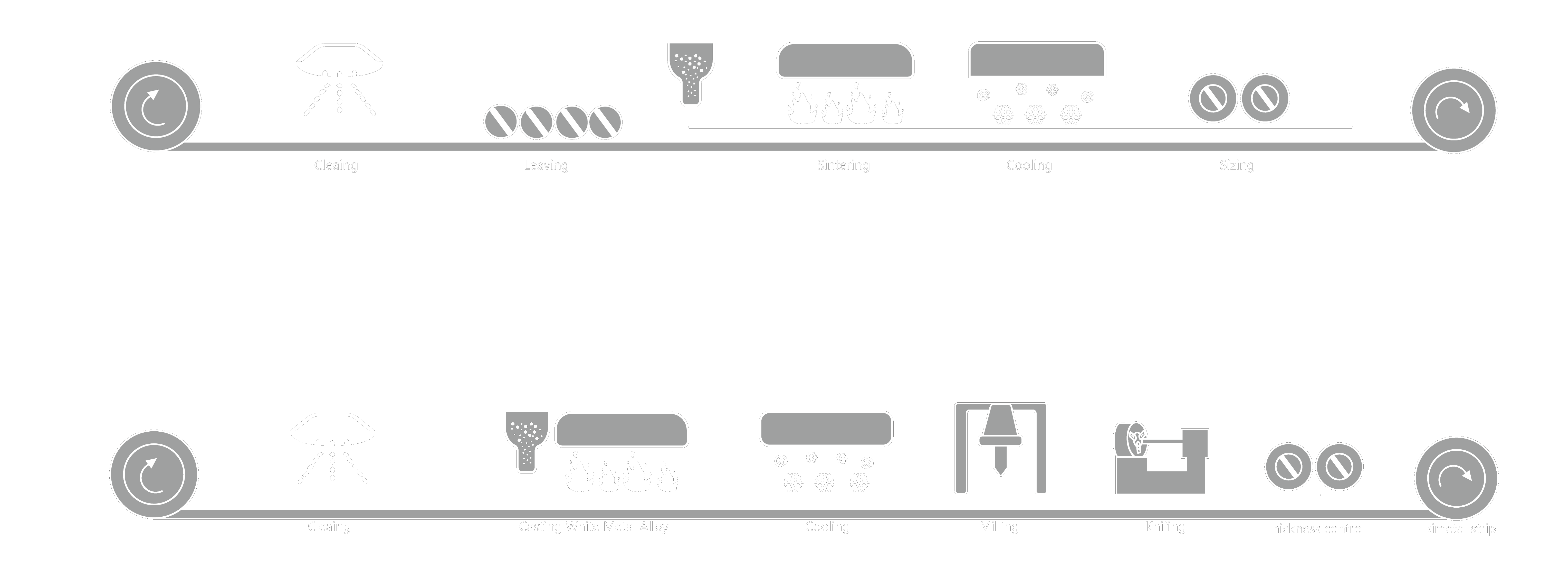

P10 material is copper powder sintered on steel base to form a certain sliding clearance, which is then formed by rollers. Because the clearance is between 0.2-0.35mm, the thickness of P10 corresponds to it 0.03mm

P10 bearing has lead added, so it cannot be used in medicine, video and other industries with environmental requirements

1. Low adhesion with parts during movement

2.Low friction and high wear resistance

3. The material has certain clearance and deformation, which can absorb the impurities produced by the movement and thus improve the life.

4 Corrosion resistance can be based on the actual use of galvanized and other solutions.

The stainless steel matrix has good chemical resistance

1. Running-in layer

| PTFE matrix with bulking agent | |

| Layer thickness [mm]: | max. 0.03 |

2. Sliding layer

| Tin-lead-bronze | |

| Layer thickness [mm]: | 0.20–0.35 |

| Pore volume [%]: | approx. 30 |

3. Bearing back

| Steel | |

| Steel thickness [mm]: | Variable |

| Steel hardness [HB]: | 100–180 |

| shaft | housing | ID | OD | Wall thickness | Oil hole | L 0 -0.40 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| h8 | H7 | d | D | T | h- | 10 | 12 | 15 | 20 | 25 | 30 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 0 -0.022 | 12 | +0.018 0 | 10 | 12 | 0.980 0.955 | 4 | 1010 | 1012 | 1015 | 1020 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 0 -0.027 | 14 | " | 12 | 14 | " | " | 1210 | 1212 | 1215 | 1220 | 1225 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 | " | 16 | " | 14 | 16 | " | " | 1415 | 1420 | 1425 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | " | 17 | " | 15 | 17 | " | " | 1510 | 1512 | 1515 | 1525 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | " | 18 | " | 16 | 18 | " | " | 1615 | 1620 | 1625 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | " | 20 | +0.021 0 | 18 | 20 | " | " | 1815 | 1820 | 1825 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 0 -0.033 | 23 | " | 20 | 23 | 1.475 1.445 | " | 2015 | 2020 | 2025 | 2030 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 | " | 25 | " | 22 | 25 | " | 6 | 2215 | 2220 | 2225 | 2230 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | " | 27 | " | 24 | 27 | " | " | 2415 | 2420 | 2425 | 2430 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | " | 28 | " | 25 | 28 | " | " | 2515 | 2520 | 2525 | 2530 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | " | 32 | +0.025 0 | 28 | 32 | 1.970 1.935 | " | 2820 | 2825 | 2830 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | " | 34 | " | 30 | 34 | " | 3020 | 3030 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | 0 -0.039 | 36 | " | 32 | 36 | " | " | 3220 | 3230 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | " | 39 | " | 35 | 39 | " | " | 3520 | 3530 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36 | " | 40 | " | 36 | 40 | " | " | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 37 | " | 41 | " | 37 | 41 | " | " | 3720 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | " | 44 | " | 40 | 44 | " | 8 | 4020 | 4030 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | " | 50 | " | 45 | 50 | 2.460 2.415 | " | 4520 | 4530 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | " | 55 | +0.030 0 | 50 | 55 | " | " | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 55 | 0 -0.046 | 60 | " | 55 | 60 | " | " | 5520 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | " | 65 | " | 60 | 65 | " | " | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For more information click here Wrapped Composite Sliding Bearing .pdf

Printing machines, lifts, textile machines, tobacco machines, fitness machines, hydraulic trucks, micromotors, solenoid valves, automobiles, motorcycles and agricultural and forestry machinery.

It is a polymer made of tetrafluoroethylene as monomer.White waxy, translucent, good heat and cold resistance, can be used in -180 ~ 260 C for a long time.This material has the characteristics of anti - acid, anti - alkali, anti - various organic solvents, almost insoluble in all solvents.At the same time, ptfe has the characteristics of high temperature resistance, its coefficient of friction is very low, so it can be used for lubrication, but also become easy to clean the ideal coating of the inner layer of the water pipe;Toxic, human carcinogen.

| Performance indicators | date | |

| Maximum load P | Static load | 250N/mm² |

| Dynamic load | 140N/mm² | |

| Maximum linear velocity V | Dry friction | 2.5m/s |

| Oil lubrication | 5.0m/s | |

| High PV value | Dry friction | 3.8N/mm²・m/s |

| Oil lubrication | 50N/mm²・m/s | |

| Coefficient of friction | 0.04~0.20 | |

| The use of temperature | -195℃~+280℃ | |

| Coefficient of thermal conductivity | 50W/m・K | |

You can choose, and choose the galvanized steel base outside, or copper plating, in order to achieve better surface salt fog test requirements, you can choose special PTFE material to reach to the requirement of the friction in the part of the parts, you can also customize the thickness of the copper powder, improve performance of shaft oilless bearing strength, so contact us, we can help you to design the bearing.