VIIPLUS INTERNATIONAL |

|

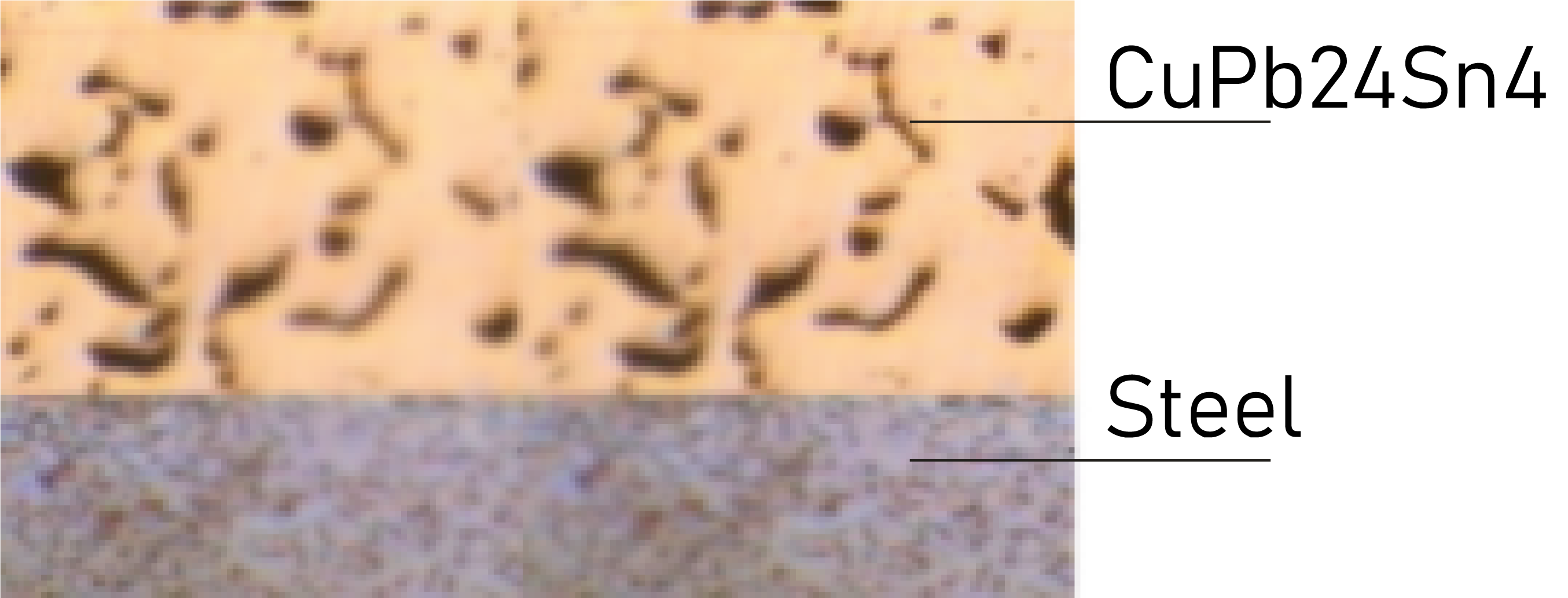

Bimetal bushings and sleeves, specifically the 800 series and 72 model, are precision-engineered components made of a unique combination of materials to achieve optimal performance in various industrial applications. The key material in these components is a copper alloy known as CuSn4Pb24.

CuSn4Pb24 is a bronze alloy composed of copper, tin, and a small amount of lead. The composition of this alloy provides several key benefits:

Wear Resistance: The addition of tin and lead to copper results in

an alloy that is highly resistant to wear. This makes it an

excellent choice for bushings and sleeves, where continuous

friction and abrasion are common.

Self-Lubricating: CuSn4Pb24 exhibits excellent self-lubricating

properties, meaning it can lubricate itself under operating

conditions, reducing the need for external lubricants. This further

enhances its wear resistance and longevity.

Corrosion Resistance: The alloy is also resistant to corrosion,

making it suitable for use in environments where exposure to

moisture, chemicals, or other corrosive agents is possible.

The bimetal construction of these bushings and sleeves combines the

wear resistance and self-lubricating properties of CuSn4Pb24 with

the strength and rigidity of a steel backing. This results in a

component that is both durable and reliable, able to withstand the

rigors of continuous use in demanding industrial environments.

In summary, bimetal bushings and sleeves made from CuSn4Pb24 and steel offer an exceptional combination of wear resistance, self-lubrication, and corrosion resistance. These properties make them ideal for use in a wide range of applications, including but not limited to machinery, automotive components, and precision instruments.

depending on lubrication conditions. In some cases, a dry bearing

can also be used under lubricated conditions.With our wide stock

availability, daily updated on our website,https://www.viiplus.com we are able to satisfy promptly every customer’s needs.

| Alloy grade | Name | Main chemical composition % | Alloy hardness HB | Steel layer hardness HB | Main use occasion | |||||

| cu | pb | sn | zn | ni | Bi | |||||

| CuPb24Sn4 | JF720 | margin | 19.0~27.0 | 3.0~4.5 | — | — | — | 55~80 | 110~140 | Bushing, bearing bush, thrust washer |

The bimetal bushings product is based on high quality low carbon steel, with sintered lead-tin bronze alloy CuSn4Pb24 on the surface. The

alloy surface can be processed into oil groove, which is convenient

for oil storage and effectively reduces wear.The steel back can be

plated with anticorrosive coating as required.This series of

products are often used in internal combustion engine spindle and

connecting rod bearings, thrust pads, rolling bearings and so on

The product is based on high quality low carbon steel and sintered

lead tin bronze alloy CuSn10Pb10.The diamond hole is rolled on the

surface of the alloy and filled with special solid lubricant to

effectively reduce wear.The steel back can be plated with

anticorrosive coating as required.It is suitable for high temperature, water solution infiltration or other occasions where oil cannot

be added or where oil is difficult.

The highest PV value is 2.8 N/mm2·m/s for grease lubrication

Matching shaft hardness 48 HRC

Oil lubrication 10 N/mm2·m/s roughness Ra=0.16~0.63

Maximum linear velocity V dry grease lubrication 2.5 m/s highest

use temperature 150 ℃

Grease lubrication 10 m/s lubrication 250 ℃

Tensile strength 150 N/mm 2 friction coefficient 0.05~0.15

Hard alloy degrees

HB 45~70 thermal conductivity 60 W/ (m·k)

Coefficient of thermal expansion

19· 10-6k-1 maximum bearing pressure P 130 n/was

d | D | 相配轴径 公差( h8) | 相配座孔 公差(H7) | 压入H7座孔 内径公差 | Wall thickness 壁厚 | 注油孔 | f1 | f2 | L 0 -0.40 | ||||||||

min | max | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | ||||||||

10 | 12 | 10-0.022 | 12+0.018 | +0.148 +0.010 | 0.995 | 0.935 | 4 | 0.5 | 0.3 | 1010 | 1015 | 1020 | |||||

12 | 14 | 12-0.027 | 14+0.018 | 1210 | 1215 | 1220 | |||||||||||

14 | 16 | 14-0.027 | 16+0.018 | 1410 | 1415 | 1420 | |||||||||||

15 | 17 | 15-0.027 | 17+0.018 | 1510 | 1515 | 1520 | |||||||||||

16 | 18 | 16-0.027 | 18+0.018 | 0.8 | 0.4 | 1610 | 1615 | 1620 | |||||||||

18 | 20 | 18-0.027 | 20+0.021 | +0.151 +0.010 | 1810 | 1815 | 1820 | 1820 | |||||||||

20 | 23 | 20-0.033 | 23+0.021 | +0.181 +0.020 | 1.490 | 1.430 | 2010 | 2015 | 2020 | 2020 | |||||||

22 | 25 | 22-0.033 | 25+0.021 | 6 | 2210 | 2215 | 2220 | 2220 | |||||||||

24 | 27 | 24-0.033 | 27+0.021 | 1.0 | 0.5 | 2410 | 2415 | 2420 | 2420 | 2430 | |||||||

25 | 28 | 25-0.033 | 28+0.021 | 2515 | 2520 | 2520 | 2530 | ||||||||||

26 | 30 | 26-0.033 | 30+0.021 | +0.205 +0.030 | 1.980 | 1.920 | 2615 | 2620 | 2620 | 2630 | |||||||

28 | 32 | 28-0.033 | 32+0.025 | 2815 | 2820 | 2820 | 2830 | 2840 | |||||||||

30 | 34 | 30-0.033 | 34+0.025 | 1.2 | 0.6 | 3015 | 3020 | 3020 | 3030 | 3040 | |||||||

32 | 36 | 32-0.039 | 36+0.025 | 3215 | 3220 | 3220 | 3230 | 3240 | |||||||||

35 | 39 | 35-0.039 | 39+0.025 | 3520 | 3520 | 3530 | 3540 | 3550 | |||||||||

38 | 42 | 38-0.039 | 42+0.025 | 8 | 3820 | 3820 | 3830 | 3840 | 3850 | ||||||||

40 | 44 | 40-0.039 | 44+0.025 | 4020 | 4020 | 4030 | 4040 | 4050 | |||||||||

d | D | 相配轴径公差(h8) | 相配座孔公差(H7) | 压入H7座孔内径公差 | Wall thickness 壁厚 | 注油孔 | f1 | f2 | L 0 -0.40 | ||||||||

min | max | 25 | 30 | 40 | 50 | 60 | 80 | 90 | 100 | ||||||||

45 | 50 | 45-0.039 | 50+0.025 | +0.205 +0.030 | 2.460 | 2.400 | 8 | 1.5 | 1.0 | 4525 | 4530 | 4540 | 4550 | ||||

50 | 55 | 50-0.039 | 55+0.030 | +0.210 +0.030 | 5030 | 5040 | 5050 | 5060 | |||||||||

55 | 60 | 55-0.046 | 60+0.030 | 5530 | 5540 | 5550 | 5560 | ||||||||||

60 | 65 | 60-0.046 | 65+0.030 | 6030 | 6040 | 6050 | 6060 | ||||||||||

65 | 70 | 65-0.046 | 70+0.030 | 6530 | 6540 | 6550 | 6560 | ||||||||||

70 | 75 | 70-0.046 | 75+0.030 | 7030 | 7040 | 7050 | 7060 | 7080 | |||||||||

75 | 80 | 75-0.046 | 80+0.030 | 9.5 | 7530 | 7540 | 7550 | 7560 | |||||||||

80 | 85 | 80-0.046 | 85+0.035 | +0.215 +0.030 | 8040 | 8050 | 8060 | 8080 | |||||||||

85 | 90 | 85-0.054 | 90+0.035 | 8530 | 8550 | 8560 | 8580 | 85100 | |||||||||

90 | 95 | 90-0.054 | 95+0.035 | 9050 | 9060 | 9080 | 90100 | ||||||||||

95 | 100 | 95-0.054 | 100+0.035 | 9060 | 9080 | 9090 | 90100 | ||||||||||

100 | 105 | 100-0.054 | 105+0.035 | 10060 | 10080 | 10090 | 100100 | ||||||||||

105 | 110 | 105-0.054 | 110+0.035 | 10560 | 10580 | 105100 | |||||||||||

110 | 115 | 110-0.054 | 115+0.035 | 11060 | 11080 | 110100 | |||||||||||

115 | 120 | 115-0.054 | 120+0.035 | 11550 | 11580 | ||||||||||||

120 | 125 | 120-0.054 | 125+0.040 | +0.220 +0.030 | 12050 | 12060 | 120100 | ||||||||||

125 | 130 | 125-0.063 | 130+0.040 | 125100 | |||||||||||||

130 | 135 | 130-0.063 | 135+0.040 | 13060 | 130100 | ||||||||||||

135 | 140 | 135-0.063 | 140+0.040 | 13560 | 13580 | ||||||||||||

140 | 145 | 140-0.063 | 145+0.040 | 14060 | 14080 | 140100 | |||||||||||

150 | 155 | 150-0.063 | 155+0.040 | 15060 | 15080 | 150100 | |||||||||||

as per drawing or sample, as drawing, Welcome Customized Drawings

Bimetal bushing VIIPLUS provides products with high compressive strength, small friction coefficient, good wear

resistance, reduce the cost of machinery manufacturing, its performance has

reached the level of similar products at home and abroad.The

products are widely used in construction machinery, textile

machinery, automobile industry, machinery industry and other

fields, especially for the parts that are difficult to oil and can

not oil have a good effect, free from oil pollution.

The enterprise takes "pursue excellence, keep improving" as the

management objective, and strives to provide customers with

first-class products and services.