VIIPLUS INTERNATIONAL |

|

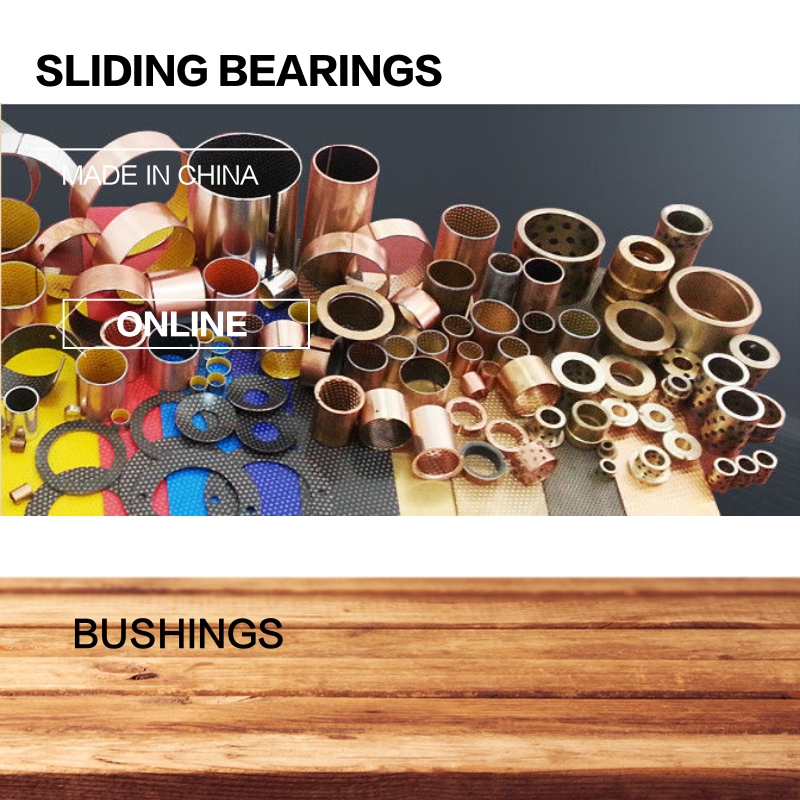

High-Load Half-Bearing Shell Steel PTFE & POM Composite

Bushings are mechanical components designed to provide smooth and

wear-resistant movement under heavy loads. These bushings are

typically made of a steel shell that encapsulates a composite

material consisting of Polytetrafluoroethylene (PTFE) and

Polyoxymethylene (POM).

PTFE, known for its excellent lubrication properties and low

friction coefficient, provides a smooth sliding surface for the

bushing. POM, on the other hand, offers good mechanical strength

and rigidity, making the composite material suitable for high-load

applications.

The steel shell of these bushings adds structural support and

durability, enabling them to withstand heavy loads and frequent

movement. The combination of PTFE and POM within the composite

material ensures that the bushings maintain their lubricity and

wear resistance over extended periods of use.

High-Load Half-Bearing Shell Steel PTFE & POM Composite

Bushings are commonly used in various industrial applications,

including automotive, aerospace, and heavy machinery, where smooth

and reliable movement under high loads is crucial.

High-load half barings PTFE/POM self-lubricating standard size qoute

Bearing shell made to order from china,which is the part in contact

between sliding bearing and shaft journal, is a shingle-shaped

semi-cylinder, which is very smooth. It is generally made of

bronze, friction reducing alloy, low carbon steel, PTFE/POM and other wear-resistant materials.Half bearings which

present excellent seizure resistance with the best load resistance.Steel/PTFE composite bearing, in 1/4,1/3,1/2,or other sizes.

Bearing bush has integral and split type two, the integral bearing

bush is usually called Bushing.Integral bearing bush without oil

groove and there are two kinds of oil groove.The bearing bush and

the shaft neck adopt clearance fit, generally do not rotate with

the shaft.

Bearing, Half Bearing, Plate, Washer made to order from china.Half

bearings which present excellent seizure resistance with the best

load resistance.

A mixture of PTFE and special fillers achieves both and abrasion-resistance and

low-friction coefficient.

Lead-free oilless resin bearings.

Providing customers of Composite bearing with the capability to reduce the risk of unplanned downtime, extend asset life, improve

performance levels and cut down on overall maintenance costs.This is

structured with a triple layered material, which contains sintered

bronze powder and special fillers with PTFE on a steel back plate.This is a boundary lubricating bearing that

performs the best against abrasion.It employs toughening agent,

lead, and tin alloy with PTFE on surface layer for better durability.

Introduction

When the sliding bearing is working, a thin oil film between the

bush and the shaft is required for lubrication.If the lubrication

is not good, there will be direct friction between the bush and the

shaft, friction will produce very high temperature, although the bush is made of special high-temperature alloy material, but the high temperature caused by direct friction is still enough

to burn it out.The bearing shell may also be burned due to

excessive load, high temperature, impurities in the lubricating oil

or abnormal viscosity and other factors.The sliding bearings were

damaged when the tiles were burned.

Thick-walled bushes can be cast to improve the friction performance

by pouring a layer of bearing alloy (called bearing lining) on the

inner surface of the bush.In order to make bearing alloy and

bearing bush stick well, various forms of mortise, groove or thread

are usually made on the inner surface of bearing bush.Thin - wall

bearing bush can be produced in large quantity by continuous

rolling of bimetallic plate.

Powder metallurgy involves mixing basic materials, such as powdered iron or copper, with graphite and then pressing and

sintering.Its pores can store lubricating oil, called oily bearing.

Bearing bush material is usually soft, the inner cylinder is not

suitable for grinding, can be boring, diamond boring, scraping or

grinding process.Grinding should not use the method of matching

with the shaft diameter, but should use a special lapping rod of

the same size as the shaft bush hole.Scraping is mostly used for

some tile bearings, scraping with wide blade scraper machine.When

scraping by hand, the scratch should be shallow.Bearing bush with

complicated inner surface should be boring in a special way

according to the specific shape.

Bearing shell material is characterized by low friction

coefficient, sufficient fatigue strength, good running-in and good

corrosion resistance.Common bearing bush materials include

self-lubricating bearing materials (PTFE), copper alloy, wear-resistant composite bearing materials, etc.

Non-lubricated bearing bush materials mainly include polymer,

carbon graphite and special ceramics.

Polymer Sliding Bush

Polymer also known as organic polymer materials, engineering

plastics.Common materials are phenolic resin, nylon, PTFE and so on.Non-lubricated bearings made of plastics (such as PTFE) are resistant to strong acids and weak alkalis, with good insert,

abrasion reduction and abrasion resistance.The ptfe sheet is pressed into lip sealing ring, bearing bush, piston ring

and gasket, which are used in belt conveyor, typewriter, sewing

machine, electric phonograph disc, water pump, textile machinery

and agricultural machinery.

Polymer has the characteristics of light weight, insulation, friction reduction, wear resistance, self-lubrication, corrosion resistance, simple molding process,

high production efficiency.Compared with metal materials, their

tribological properties are sensitive to ambient temperature and

humidity, and have significant viscoelastic properties, so the gap

between bearing bush and journal is large.Because of its low mechanical strength, small elastic modulus, poor absorption of

lubricating oil, and limit the working speed and pressure value of

bearing bush.

Related Products Graphite Bronze Bushing

The sliding bearing thurst washer & plate - graphite

material can be used in harsh environment.The more graphite, the

softer the material, the smaller the friction coefficient.

oilless bearing bushing (PTFE Composite) |

slide bearing bushing (POM Composite) |

Bronze bushing |

Bronze bushing through holes |

solid graphite lubricating bushing |

bi-metal bushing |

sintered bronze |

PTFE sliding bearings strips |

JGB Graphite bearings |

Metal bearing is an important part to support a connecting rod and

a crankshaft to rotate in an engine for automobiles, motorcycles,

construction machinery or ships.

Half bearing is divided into two parts to cope with the complex

shape of the installation point.

Good in abrasion resistance, load resistance, impact resistance,

and heat resistance. It can be used for places where the speed and

the load would be a problem.

We are available to have through meetings with you to offer

services and advice on what is the best for your purposes at the

most affordable prices.

FOLLOW US ON

HTTP://WWW.BRONZEGLEITLAGER.COM