VIIPLUS INTERNATIONAL |

|

When it comes to reliable and dependable spring pin bearings and bimetal bushings, our company stands as a trusted supplier in China. We specialize in providing high-quality spring pin bearings and bimetal bushings that meet the stringent requirements of various industries.

Our spring pin bearings are precision-engineered using advanced manufacturing techniques and high-grade materials. These bearings are designed to offer superior wear resistance, durability, and performance in demanding applications. Whether you need bearings for heavy-duty machinery, automotive components, or any other industrial application, we have the right solution for you.

In addition to spring pin bearings, we also offer a wide range of bimetal bushings. These bushings are made from a combination of two different metals, which results in a material with exceptional properties. The bimetal design provides superior strength, hardness, and wear resistance, making our bushings ideal for high-load and high-speed applications.

As a leading supplier in China, we pride ourselves on our commitment to quality and customer satisfaction. We ensure that each product we supply meets the highest standards of performance and reliability. Our team of experienced engineers and technicians is dedicated to providing you with the best possible solutions for your specific needs.

Whether you're looking for spring pin bearings, bimetal bushings, or any other type of precision bearing or bushing, our company is your trusted supplier in China. Contact us today to learn more about our products and services.

Bimetal Buahing Supplier - China Bimetal Bushing Supplier

Steel backing strip with a sintered bronze layer, Super Low MOQs

for Customized Order Selected Items Starting at 30% Off.Specializes

in Bimetal Strips & Sheet, bimetal bearings Plate. Different

specs, Custom-made. Dedicated to R&D of metals self-lubricating

bearings technology, Factory price. Specification: Customized.

Available in Metric Size and inches zie. Multilayer Composites.

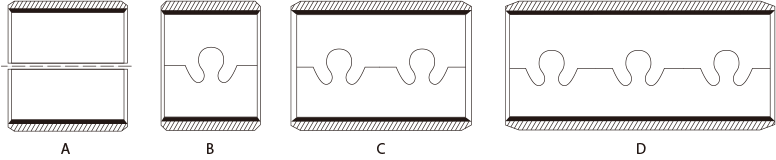

The advantages of wear resistance of bimetallic bearings

Bimetallic bearing products have the advantage of good wear

resistance. Especially suitable for medium and low-speed stripping

as described. Through a special process, all kinds of oil can be

produced in the groove, oil hole, and hole on the friction surface

to adapt to the use of different lubrication conditions. The

products have been widely used in automobile engines, chassis,

motorcycle clutch, gear pump, cleaning and elevator equipment, and

other fields.

Base metal inlaid solid self-lubricated bearing is a novel

characteristic of metal bearing and self-lubricated bearing, made

of metal substrate loaded, solid lubricated material especially

lubricant. It has the high bearing capacity, impact resistance,

high-temperature resistance, self-lubricating characteristics, and

other capabilities, especially suitable for heavy load, low speed,

reciprocating or swinging, such as lubrication and oil film is

difficult to form, not afraid of water, and other acid etching and

washing.

Bimetallic bushings with SAE1010 steel shell and sintered bronze/aluminum alloy lining.

Bimetal Bearings has high-performance environmental-friendly dual metal bearings that are customer-specified products. Bimetal Bearings uses a low-carbon steel plate as supporting base and powder metallurgy sintering and rolling processes to form a leadless CuSn8Ni steel-copper alloy product. The materials in this product meet the RoHS directory/regulation/rule. Bimetal Bearings has the high load-bearing capacity and good wear-resistance. Its shortcoming is that it cannot be used without oil lubrication. In places where oil lubrication is sufficient, Bimetal Bearings has superior performance.

| Base material | CuSn8Ni | Temperature | 200℃ |

| Load capacity | 140N/mm² | Alloy layer hardness | HB90~120 |

has a bi-layer structure of low carbon steel backing and copper

alloy (CuSn6.5P0.1) sliding layer. This product is lead-free. To

decrease abrasion, oil grooves can be formed on the surface of

alloy. According to the requirement, the steel back can be plated

with anticorrosive coating. bimetal bushings series products are

often used as wrapped bushes, thrust washer and bushes on mainshaft

and connecting rod of internal combustion engine.Steel backing can

be copper plated Steel+CuSn6.5P0.1 Basic concept of composite bimetallic bearing

Bimetal bearing is one of the oil-free smooth bearings. The

compound bearing is made of high quality low carbon steel back with sintered lead-tin bronze

alloy on the outside.It has the characteristics of high bearing capacity, impact

resistance, high temperature resistance, strong self-smoothness,

etc., especially suitable for heavy load, low speed, reciprocating

or rocking, etc., which is difficult to smooth and form oil film,

and is not afraid of water flushing and other acid corrosion and

erosion.

Because the substrate is stable for low carbon steel, so the

machining accuracy of the outer diameter is guaranteed, and dry

bearing in the product into the seat hole does not need screw

fixation, relying on interference cooperation can avoid the

phenomenon of going round.The modification of the chemical composition of inner surface alloy

layer can satisfy the requirements of different bearing pressure,

different operating temperature and different sliding speed.

Bimetal bearing has the advantages of good wear resistance, especially suitable for medium speed and low

speed and high load.Through special technique, it can process

various oil groove, oil hole and oil hole on the conflict surface,

and then adapt to different smooth conditions.The products are mainly used in the balance bridge bushing and

gasket of heavy duty vehicles.Automobile engine, chassis,

motorcycle clutch, gear pump cleaning plate and lifting equipment

and other categories.

JF800 Bimetallic Bearings Bushing Made in China JF800 bush,bimetal bush Introduction Bi-Metal bushing is composed of high quality low carbon steel and bronze with the characters of wear high speed, high load capacity, very compact dimensions, low wear.

Spilled bimetal bushings Product DescriptionJF800 / SAE797. JF800 Bimetallic Bearing's

steel-bronze-compound material with indents as a reservoir for the

grease. JF800 Bimetallic Bearings has high load capacity, very good

resistance to fatigue strength at higher temperatures. JF800

Bimetallic Bearings is applicable in rough operation conditions.

JF800 Bimetallic Bearings

The product is made with a high-quality low carbon steel plate as matrix,the surface is sintered with lead green aluminum alloy,

and it is made through many times of sintering and rolling.It has

medium fatigue strength and good surface performance of bearing.The

products are mainly used for connecting rod bearing of the spindle

on the internal combustion engine.

By studying sliding bearings and surface engineering, VIIPLUS is working to create an ideal world where friction losses can be minimized.With r&d, testing and production in China, VIIPLUS works with customers worldwide to design and develop efficient and environmentally friendly tribology solutions.VIIPLUS engineers bring their expertise and love of tribology to the automotive, aerospace and industrial manufacturing industries.For more information on surface engineering tribology of VIIPLUS sliding bearings, visit www.bronzegleitlager.com

Bimetal bushing advantages:

1.High precision.

2.High efficiency.

3.High quality

4.Quick delivery

5.Stable and reliable performance.

6.Hard-wearing.

7.Two million times Working life

8. usually in stock on the regular model number

9. Much more manufacturing experience

10. Samples available

11. Nice appearance, complete product system

12. We can make non-standard linear bearing according to clients'

samples or drawings.

Infrastructure, Energy Generation, Resources, Renewables, Biomass Energy, Engineering Bearings

VIIPLUS offers a broad range of sizes, forms and materials in monometallic

and bimetallic bearings. Bimetal and metal bearings offer excellent

corrosion resistance in industrial outdoor applications and in

water, marine and offshore environments. VIIPLUS bearings can be

made in many sizes and forms, including thin-walled, thick-walled,

flanged, cylindrical, sintered and oil-impregnated, and more. Some

popular bearing materials and their benefits include:

Bimetal bearings are able to handle heavy loads and shock loading

conditions. Our bimetal bearings have anti-corrosion capabilities and are easy to install, making

them ideal for emergency replacements. VIIPLUS( JF800 )bearing is available with stainless steel, carbon

steel or bronze backing.

Because the matrix is stable as low carbon steel material, so the machining accuracy of the outer diameter of

the shaft sleeve has been guaranteed, and there is no need for

screw fixation after the product is loaded into the seat hole,

relying on interference fit can prevent the phenomenon of going out

of the circle.The change of chemical composition of inner surface

alloy layer can meet the requirements of different bearing

pressure, different service temperature and different sliding

speed. The oil groove and oil hole with different structure are

designed in the production of friction surface to meet the

requirements of different ways of oil adding, prevent shaft biting

and adapt to different lubrication conditions.

Widely used in automobile engine, motorcycle clutch, light

industrial machinery, construction machinery.

Alloy layer material CuPb10Sn10 or CuSn6Zn6Pb3

Suitable for low speed, heavy load or intermittent movement conditions, lubricating oil film can not form or maintain the occasion;

Suitable for the working environment or mechanical structure

restrictions, it is difficult to supply oil lubrication occasions;

It is suitable for rotating, reciprocating, swinging, linear and

other forms of movement, as well as occasions requiring frequent

starting or starting under high load;

Suitable for high or low-temperature work, or the environment temperature range of large occasions; Good corrosion resistance, can be used in seawater and other corrosive media such as

chemical liquids or gases, as well as water containing sediment or

the radioactive environment;

Non-water absorption, good dimensional stability, high mechanical

strength, good thermal conductivity;

Bearing is a thin wall structure, lightweight, small volume,

suitable for compact design;

Compared with the traditional three-layer composite material, the

static load characteristics, wear-resistance, service temperature, dimensional stability and so on under the

condition of non-grease lubrication are better;

Compared with copper inlaid self-lubricating material, it is more

suitable to work under the condition of small Angle swing, and the

price is cheaper.

| GENERAL | Unit | Value | |

| Maximum load, p | Static Dynamic | N/mm2 N/mm2 | 300 140 |

| Operating temperature | Min Max greased Max oil lubricated | °C °C °C | - 40 150 250 |

The products are applied to water conservancy and hydropower industry: hydraulic machinery: horizontal support slide of hydraulic steel gate, support bearing of the hydraulic hoist and closure machine, sandblasting maintenance door bearing, etc. Hydraulic turbine: guide vane shaft sleeve (upper guide, middle guide, lower guide), wheel shaft sleeve, pin shaft sleeve (connecting rod pin, push and pull rod pin, relay piston pin), anti-wear ring plate (thrust ring), anti-wear block, control ringside tile.

Metallurgical industry: die-casting machine bearing, rolling

cutting shears (bilateral shears, fixed-length shears on the

skateboard), etc.

Valve industry: butterfly valve, globe valve, etc.

Others: mining machinery, packaging machinery, construction

machinery, heavy machinery, injection molding machine, automobile

tire mold, wind turbine, thermal power, and other industries.

Wrapped composite sliding bearing

Copper-plated or tin-plated steel/bronze

Low-maintenance

With lubrication pockets

For high load capacity and oscillating movement, as well as for rough operation and temperature load. Long-run lubrication because of lubricant storage.

Support materialSteel copper-plated / tin-plated

Sliding layer CuPb10Sn10

Specific load capacity static≤ 250 [N/mm2]

Specific load capacity dynamic≤ 140 [N/mm2]

Sliding speed≤ 2,5. [m/s] ≤ 5 [m/s] oil lubricated

Reibungswert **0.04 [µ] to 0.12 [µ] depending on lubrication

Temperature strain– 40 [°C] to + 250 [°C]

Max. PV-value2.8 [N/mm² x m/s]

Percentage contact area > 75 [%]

Housing ØH7

Bushing inner-Ø after mountingH9

Shaft tolerancef7 to h8

viiplus bimetal is a low-maintenance composite sliding bearing, but primary lubrication is necessary. Oil or grease lubrication is possible. Due to solid lubricant storages, lubrication clearances are reduced to a minimum!

Special dimensions are available on request

FOLLOW US ON

www.bronzegleitlager.com