VIIPLUS INTERNATIONAL |

|

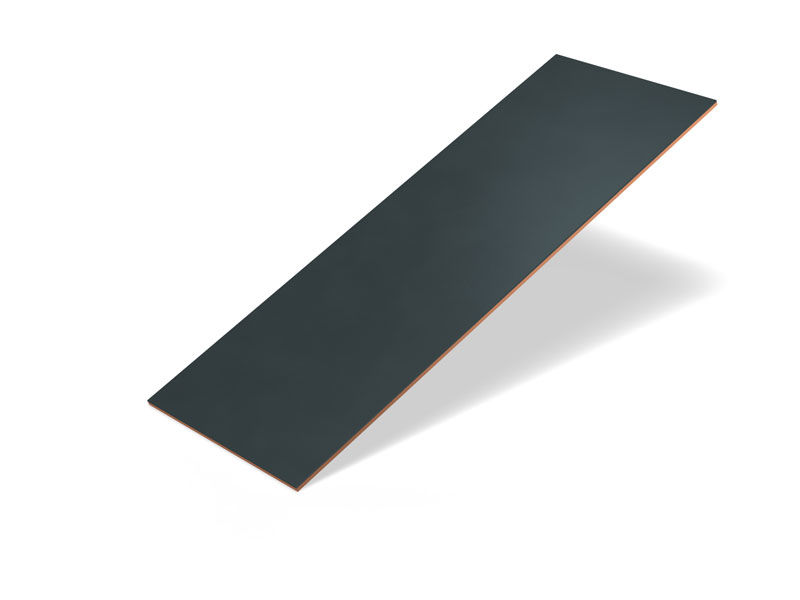

PTFE skidway plates or skidway plates VSB-11 Dry Sliding Bearing Strips are specifically designed for oscillating and rotating movements. These bearing strips are made of polytetrafluoroethylene (PTFE), also known as Teflon, which possesses excellent properties such as low friction, high chemical resistance, and high temperature tolerance.

The VSB-11 Dry Sliding Bearing Strips are commonly used in various industrial applications where oscillating or rotating motions are involved. Their dry sliding properties eliminate the need for lubrication, thus simplifying maintenance and reducing the risk of contamination.

The skidway plates feature a smooth surface that ensures consistent and reliable sliding, even under high loads and varying temperatures. They are also lightweight and easy to install, making them a convenient choice for a wide range of applications.

Overall, PTFE skidway plates or skidway plates VSB-11 Dry Sliding Bearing Strips are an effective solution for supporting oscillating and rotating movements in various industrial settings.

Bronze base bearing self-lubricating bearing tin bronze is of high

safety factory,and is particularly appropriate for high temperature

environment where no oil is effcient and where the machine must be

under successive long period working condition.

This is widely used in steel metallurgy industry such as bushes for

roller grooves of successive casting machines.cement grouting pumps

and screw convery ers for cement.It can also be composed in steel

housing or fabricated into Flanged bushes which can move both in

radial and in axial directions.

Bronze base bearing self-lubricating bearing tin bronze, bearing sleeve for metallurgical iron and steel industry, bearing sleeve for continuous caster billet raceway, bearing for equipment in front of high temperature furnace, bearing sleeve for cement grouting pump and screw conveyor.

Bronze base bearing is made of tin bronze as matrix, sintered

bronze spherical powder in the middle, rolled PTEE on the surface

and high temperature resistant filler material.

It has a high safety factor, in the continuous work can not stop

repair places and high temperature can not be refueled in places.At

present, it has been widely used in metallurgical iron and steel

industry, continuous casting machine billet runner,

high-temperature furnace equipment, cement grouting pump and screw

conveyor.It can be combined with steel sleeve, also can be made

into flanging, to achieve the end face, inner hole friction effect

at the same time.

The grouting pump is designed to overcome the shortcomings of the above existing technologies, provide a kind of ground source heat pump ground pipe backfilling equipment that is convenient to transport, install, operate and use, easy to maintain and repair, and can meet all grouting filling requirements in the environmental protection geothermal application construction.

The pump head of the grouting pump is mainly composed of the pump head, bearing, shaft sleeve, self-lubricating bearing, ball valve seat, inlet valve cover, exhaust valve cover, steel ball and so on. In order to ensure the smooth next grouting, please be sure to clean the pump and pipe after grouting.

The rolling part of the bridge support is to replace the pure PTFE

plate with the thickened vsb-11 wear-resistant layer.Up to 130N/mm

carrying requirements.

SF-1B bronze-based material is made of tin bronze plate as the

base, sintered bronze spherical powder in the middle, surface

rolled PTFE and high temperature resistant filler. It has a high safety factor and is particularly suitable for use

in places where continuous work cannot be stopped and where it

cannot be refueled at high temperatures. At present, the material

has been widely used in the metallurgical steel industry,

continuous casting machine billet rolling, high temperature furnace

front equipment, cement grouting pump and screw conveyor. It can be

combined with steel sleeves on the outside or flanged to achieve

the effect of friction between the end faces and the inner holes.

The sliding part of the bridge support is to replace the pure PTFE

board with the SF-1B wear layer thickening product. Meet the

requirements of 130N/mm2 load bearing.

Maximum load pressure: 140N/mm2

Friction coefficient μ: 0.03~0.18

Applicable temperature range: -195 ° C ~ 300 ° C

Maximum sliding speed: 5m/s

Allow the highest PV value (dry): 4.3N/mm2.m/s

Allowable maximum PV value (oil): 50N/mm2.m/s

Cylindrical bushes Collar bushes

Thrust washers Strips

Table of Contents

Material information

Plain bearing production

Characteristics:Material information

Material composition

Models and tables of dimensions

More information

VSB-11 Metal-Polymer Bronze Backed PTFE Plain Bearing

Bronze + Bronze Powder + PTFE/Fibre

CHARACTERISTICS

· VSB-11

· Very good wear and low friction performance over a wide range of

loads, speeds and temperatures in dry running conditions

· Suitable for lubricated applications

· Suitable for linear, oscillating and rotating movements

· Bronze back offers improved corrosion resistance in humid/saline

environments

· Suitable for dry running, low coefficient of friction, lower

wear, good sliding characteristics, the transfer film created can

protect the mating metal surface, suitable for rotary and

oscillating movement. Very high chemical resistance, low absorption

of water and swelling, also performs very good lubrication feature,

the bronze backing provides the improved corrosion resistance

comparing with VSB-10.

1. PTFE/fibre mixture thickness 0.01~0.03mm, provides an excellent initial

transfer film, which effectively coats the mating surfaces of the

bearing assembly, forming an oxide type solid lubricant film.

2. Sintered bronze powder thickness 0.20-0.35mm, provides max.

thermal conductivity away from the bearing surface, also serves as

a reservoir for the PTFE/Fibre mixture.

3. Bronze backing, provides exceptionally high load carrying

capacity, excellent heat dissipation and very good corrosion resistance.

· Metal-Polymer Composite Material

· Bronze Back + Porous Bronze Sinter +

· PTFE + Lead

| Sliding layer PTFE |

| Max. load | Static | 250N/mm2 |

| Dynamic | 140N/mm2 | |

| Max. speed | Dry | 2m/s |

| Lubrication | >2m/s | |

| Max. PV (Dry) | Short-time | 3.6N/mm2*·m/s |

| Continuous | 1.8N/mm2*·m/s | |

| Temp. | -195℃~+2800℃ | |

| Friction coefficient | 0.03~0.20 | |

| Thermal conductivity | 70W (m·k)-1 | |

| Coefficient of thermal expansion | 17*10-6k-1 | |

OPERATING PERFORMANCE | |

Dry | Very Good |

Oil lubricated | Good |

Grease lubricated | Fair |

Water lubricated | Good |

Process fluid lubricated | Fair |

* Depending on operating conditions

Bearing forms available in standard dimensions

· Cylindrical bushes

· Flanged bushes

· Sliding plates

Bearing forms made to order: standard forms in special dimensions,

thrust washers, flanged thrust washers, half-bearings, special

shapes obtained by stamping or deep drawing, customized bearing

designs

The typical applications covered Steel metallurgy industry such as

bushes for roller grooves of successive casting machines, cement

grouting pumps and screw conveyers for cement and so on.conducts

the thermal build up away from the bearing surfaces.

3. Low-carbon steel.Setting the foundation of the bushings, the steel back provides

exceptional stability,load carrying and heat dissipation

characteristics.

START YOUR

PROJECTWITH AN APPLICATION ENGINEER