Halstec Engineering Co., Ltd |

|

Verified Suppliers

|

|

High Grade Face Brick Production Automatic Brick Making Machine with 1 Year Warranty, Twice Setting System

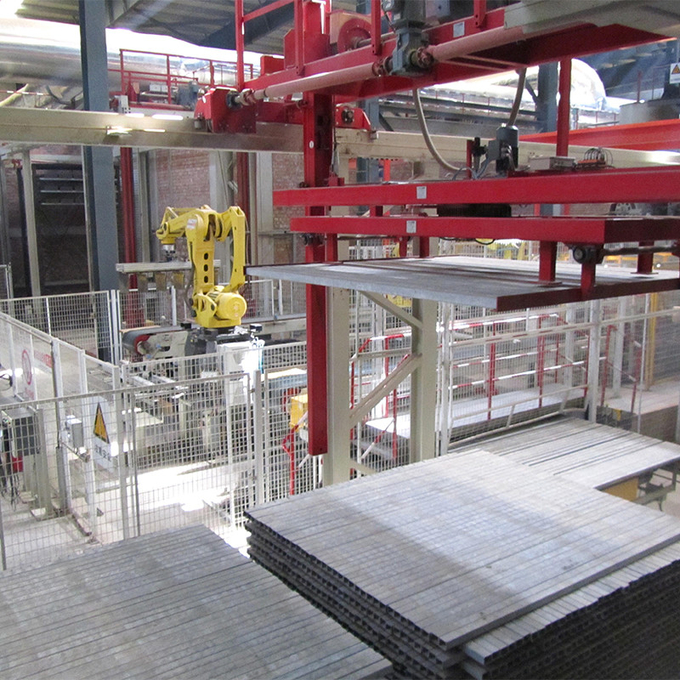

The Halstec Twice-setting loading and unloading sytem is the important machine for producing high-grade face bricks and wall materials, this sytem combined by the vertical cutting machine, pallet loading system, transporting device, pallet unlaoding system, automatic control system, etc. All designs combine into one system and controlled by the programm to finish the brick stacking by layers.

The Twice-setting System is perfect solution for those who want to out-wall bricks, wall panels. Because the face bricks has a high quality standard, the surface should be smooth, with even color, can not have the stacking indentation. According to these requirements, then the wet bricks must be separate and place on the pallet, then to dry on the pallets.

This design is mainly for the good quality brick production, not for the higher output production. So when you have plan to make higher-grade bricks, such as face bricks, hollow bricks, wall panels etc.

The Halstec Twice-setting loading and unloading sytem is the important machine for producing high-grade wall materials, this sytem combiend by the cutting, pallet loading system, transporting device, pallet unlaoding system, automatic control system, etc. All designs combine into one system to produce high-grade face bricks, hollow bricks, wall panels, etc.

| Property | Value |

|---|---|

| Structure | Pallet Loading And Unloading System |

| Warranty | 1 Year |

| Size | 6*40’ Container |

| Power | 50-200KW |

| Certification | CE, ISO9001 |

| Feature | Fully Automation System |

| Function | Stack Bricks By Pallets |

| Service | Overseas Installation And Commissioning |

| Name | Brick Loading And Unloading System |

| Pressure | 0.5MPa-0.75MPa |

Our team of experienced professionals provide technical support and services to ensure that your Automatic Brick Making Machine is running properly and efficiently. We offer a wide range of services, from installation and training to troubleshooting and maintenance.

We offer installation and training services to ensure that your Automatic Brick Making Machine is set up correctly and running smoothly. Our team will work with you to determine the best setup for your needs and provide the necessary training to ensure that your employees are comfortable and confident with the machine's operation.

Our team is available to provide troubleshooting and maintenance services for your Automatic Brick Making Machine. We offer routine maintenance and repairs to keep your equipment running smoothly and efficiently. If a problem arises, our team is available to provide fast and effective solutions.

We provide customer support services for our Automatic Brick Making Machine. Our team is available to answer questions and provide guidance. We are committed to providing excellent customer service and ensuring that our customers are satisfied with their purchase.

Clay Brick Making Machines are tested and packed before delivery. Most cargoes are directly loaded into the container, then will be fastened by the steel wire, and fasten belt. Some small spare parts will be packed in the wooden box or the iron boxes. Then loaded into the container or the heavy trucks by the forklift.

During the production, if any spare parts are in urgent need,

Halstec will arrange DHL, FedEX, UPS, or by air to your project

location as soon as possible, to ensure your continuse production.

Choose Halstec, choose an easy way to success!

Finished Brick Samples

According to different usage purpose, finished bricks can be divided into out-wall decoration bricks, and inner-wall construction bricks.

Out-wall decoration bricks come with smooth surface and uniform color , and normally burning fuel is natural gas or coal powder, which is showered into the burning kiln by specific tube system. Out-wall decoration bricks also can be called as Face bricks.

Inner-wall construction bricks, normally featured with rough surface, but higher strength. Burning fuel for inner-wall construction bricks is coal, which can be added into the raw materials, or threw from the top of burning kiln.

Below is the sample for finished bricks, the size, shape and hole rate can be customized as the production requirements of clients.

Customers Show

With around 20 years experience of international trading, Halstec has set up more than 200 brick factories all over the world, such as Indonesia, Uzbekistan, India, Myanmar, Vietnam, South Africa, Zimbabwe, Bangladesh, etc. Below is the glimpse of our clients, hope can be your partner in very soon future.