Halstec Engineering Co., Ltd |

|

Verified Suppliers

|

|

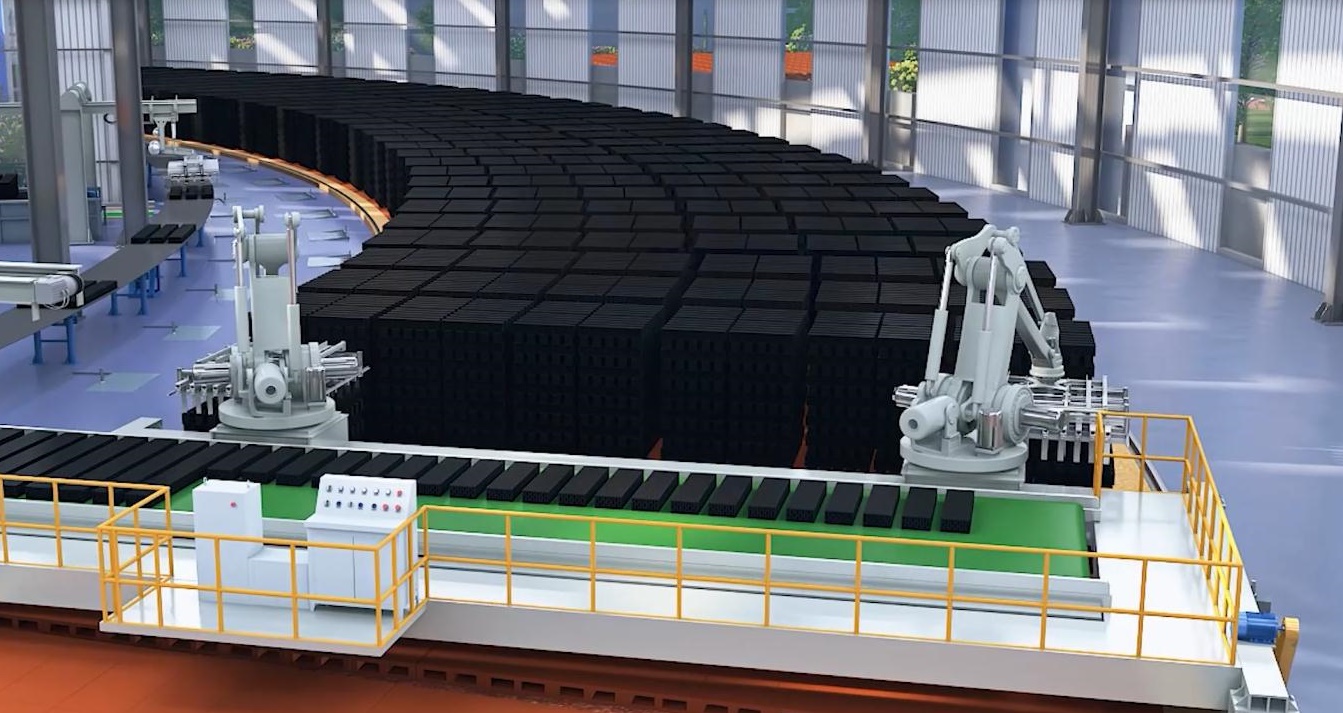

Movable Rotary Kiln Easy Operation Tunnel Kiln, Dry and Burn Bricks, 12.98m section

Movable Rotary Tunnel Kiln is a type of kiln with movable drying and burning design that is used for clay brick production line. It has a capacity of up to 100000 to 200000 bricks per day. It is mainly used for wet bricks drying and buring. It is energy efficient and has a one year warranty. It also has a low carbon emission rate. It is reliable and durable for many years of use. It is easy to operate and maintain and provides high quality products. It is also safe and environment friendly. Movable Rotary Tunnel Kiln is a perfect choice for those who want a cost-effective and efficient way to produce bricks.

Halstec is a famous brand of tunnel kiln from China. Our rotary tunnel kilns are used to dry and burn bricks with a capacity of 100000 to 200000 per day. The kiln has been certified with CE and ISO, and is easy to operate. The raw material for the brick production line is clay, and all the kilns are packaged in containers. Halstec tunnel kilns are the perfect solution for the clay brick production by the automatic method.

| Parameter | Description |

|---|---|

| Method | Movable Rotary Tunnel Kiln |

| Environmental | Friendly |

| Warranty | One Year |

| Processing | Brick Production Line |

| Certification | CE ISO |

| Capacity | 100000 To 200000 Per Day |

| KILN SECTION | 7.2m 10.8m 12.98m 16.8m |

| Features | High Efficiency |

| Operation | Automatic |

| Brick Raw Material | Clay |

| Tunnel Kiln | Rotary Tunnel Kiln, Electric Tunnel Kiln, Rotary Tunnel Kiln, etc. |

We are committed to providing the highest quality technical support and services for our Tunnel Kiln products. Our team of experts is available to answer any questions you may have about installation, maintenance, and repair of our Tunnel Kiln products.

We offer a comprehensive range of technical services, including on-site installation and maintenance, online troubleshooting and remote diagnostics, as well as telephone and email support.

We are proud to provide a dedicated after-sales service team, available 24/7 to ensure your Tunnel Kiln products are running smoothly and efficiently.

For more information about our Tunnel Kiln technical support and services, please do not hesitate to contact us.

Clay Brick Making Machines are tested and packed before delivery. Most cargoes are directly loaded into the container, then will be fastened by the steel wire, and fasten belt. Some small spare parts will be packed in the wooden box or the iron boxes. Then loaded into the container or the heavy trucks by the forklift.

During the production, if any spare parts are in urgent need,

Halstec will arrange DHL, FedEX, UPS, or by air to your project

location as soon as possible, to ensure your continuse production.

Choose Halstec, choose an easy way to success!

Finished Bricks

According to different usage purpose, finished bricks can be divided into out-wall decoration bricks, and inner-wall construction bricks.

Out-wall decoration bricks come with smooth surface and uniform color , and normally burning fuel is natural gas or coal powder, which is showered into the burning kiln by specific tube system. Out-wall decoration bricks also can be called as Face bricks.

Inner-wall construction bricks, normally featured with rough surface, but higher strength. Burning fuel for inner-wall construction bricks is coal, which can be added into the raw materials, or threw from the top of burning kiln.

Below is the sample for finished bricks, the size, shape and hole rate can be customized as the production requirements of clients.

Customer Show

With around 20 years experience of international trading, Halstec has set up more than 200 brick factories all over the world, such as Indonesia, Uzbekistan, India, Myanmar, Vietnam, South Africa, Zimbabwe, Bangladesh, etc. Below is the glimpse of our clients, hope can be your partner in very soon future.

A1.Tunnel Kiln is a continuous indirect fired kiln used for high volume production of ceramics and refractories.

A2.The brand of Tunnel Kiln is Halstec.

A3.Tunnel Kiln is from China.

A4.The certification of Tunnel Kiln is CE/ISO.

A5.The packaging Details of Tunnel Kiln is Nude in the container.