KELI MACHINE Co,. Ltd |

|

Verified Suppliers

|

|

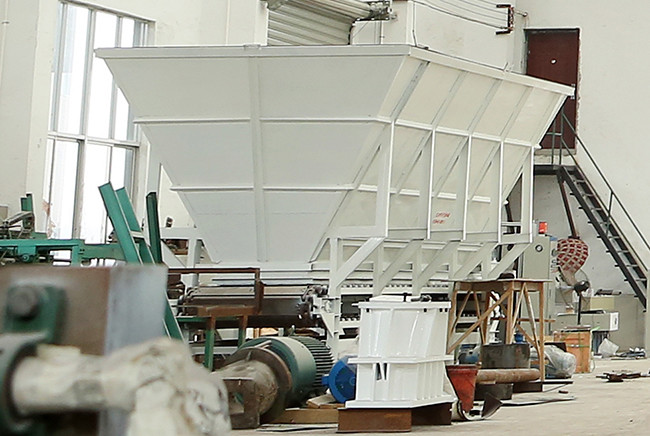

Clay Brick Making Machine Boxfeeder Production Capacity Range 5-150m³/h

| Product Introduction | |||||

Adopting high-quality new steel plate, the channel steel adopts the national standard, and the box type earth-filling box adopts three-speed shifting. | |||||

Product Parameter | |||||

| Name | Unit | GL4.6/1000 | GL6/1000 | GL8/1000 | GL6/1500 |

| Effective width of fender at outlet | mm | 800 | 800 | 1200 | 1200 |

| Distance between shafts | mm | 4500 | 5000 | 6000 | 6000 |

| Loading power | kw | 4 | 4 | 5.5 | 7.5 |

| Distributor power | kw | 2.2 | 2.2 | 3 | 4.0 |

| Weight (incl. Motor) | kg | 6800 | 8800 | 10000 | 14200 |

| Dimensions | m | 5.5*1.8*1.7 | 7*1.8*1.7 | 8.5*1.8*1.7 | 7.5*2.4*1.9 |

| Production capacity range | m³/h | 5-150 (according to different material characters) | |||

| Structure | |||||

It consists of three parts: storage, drive and conveying device for storing clay and continuous uniform feeding. | |||||

| Uses | |||||

It is a device for uniform and quantitative feeding. By adjusting the height of the ram, there is a speed of the conveyor belt, controlling the feed amount of the raw material, and breaking the large loose mud. And through the adjustment system, the speed of the conveyor belt is controlled, the feedstock of the raw materials is controlled, and the mud and the raw materials are proportionally squeezed. This machine has the functions of mixing and shredding, and it is one of the important equipments that must be used by medium and large brick and tile enterprises. | |||||

| Applicability | |||||

It is suitable for uniform feeding of clay, fly ash and scattered shale, coal gangue and other materials with water content not more than 20%. (Applicable to uniform fabrics of clay or loess and coal gangue with a relative water content of 23% and a particle size of not more than 250 mm.) | |||||

After sales service

1. We have many years of work experience and mature operation technology

2. Our engineers can go to the site to guide the installation.

3. We provide 24 hours online guidance.

Before the customer purchases the machine, the company sends engineering and technical personnel to the user's site for free to plan the site, design the best process and solution for the user; After purchasing the machine, dedicated after-sales service personnel will be assigned free of charge to guide customers in installation and debugging, assist customers in planning and managing the equipment, and ensure customer satisfaction. The company not only has a skilled and experienced after-sales team, but also closely follows the trend of E-generation, creating a pioneer in e-commerce in the industry. The implementation of internet sales and tracking services not only extensively promotes the company's products, but also provides convenient after-sales services for customers.