Zhangjiagang City Bievo Machinery Co., Ltd. |

Automatic Rotary Type Viscous Liquid/Cream/Lotion/Cosmetic Filling Machine

Introduction of Automatic RotaryType Viscous Liquid/cream/lotion/cosmetic Filling Machine::

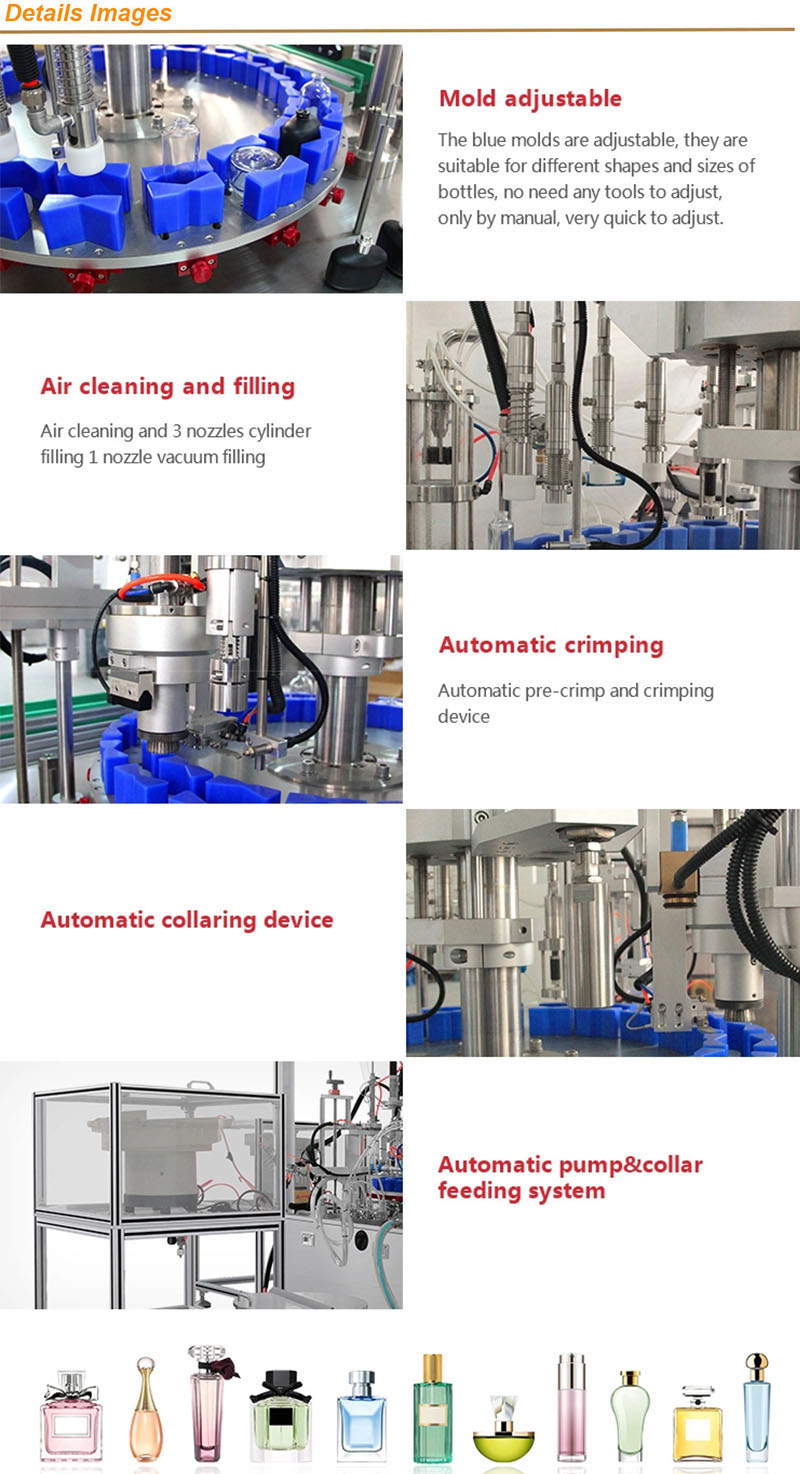

This machine is including air cleaning- filling- inner cap

inserting- capping system. It is suitable for lotion, shampoo,

cream and so on.

1. Automatic air cleaning- filling- inner cap inserting- capping,

each part has two heads.

2. Air cleaning system: cleaning dust and impurities.

3. Filling system: Servo motor control, rotary vale filling. High

filling accuracy, suitable filling high foam liquid, can self-suck

when filling water type liquid.

4. The hopper is with liquid level detection system. Simple

operation and adjust

5. Adjustable molds: suitable for different sizes of bottles

6. Screw filling system: suitable for any of the screw caps. The

cap contacting material is soft silicone, this material won’t scrap

cap.

7. Anyone can skillfully operate without training

8. Movable with wheel.

Detergents & Chemical Liquid.

Suitable of Automatic RotaryType Viscous Liquid/cream/lotion/cosmetic

Filling Machine: :

detergent, shampoo, dishwasher, liquid soap,oil, hand santizer.etc

Bottle Material : PE PP Bottle

Bottle Type : Round / Square / Unique

Cap : Screw cap/ Pump cap

Label : Sticker Label

Technical Parameter of Automatic RotaryType Viscous Liquid/cream/lotion/cosmetic

Filling Machine::

1. Capacity: 40-45 bottles per minute

2. Material: Stainless steel304&316

3. Usage: filling for lotion,cream, shampoo,liquid

soap,toner,conditioner, etc

4. Filling volume: 15-250ml

5. Function: automatic air cleaning, filling, collaring and screw

capping

6. Filling accuracy: ±1%

7. Filling nozzle: 2 pcs

8. Air Pressure: 0.5MPA

| Machine frame | SUS304 Stainless steel | |

| Contact material parts | SUS316L Stainless steel | |

| Main Motor | ABB | Switzerland |

| Inverter | Mitsubishi | Japan |

| Air Switch | Schneider | France |

| Contactor | Schneider | France |

| Relay | Omron | Japan |

| OFA | Autonics | Korea |

| Bearing | IGUS | Germany |

| CAM indexer | Shangdong | China |

| Turntable | Plastic POM | Japan |

| Cylinder | AIRTAC | Taiwan |

| Touch screen | Siemens | Germany |

| PLC | Siemens | Germany |

| Servo motor driven | Mitsubishi | Japan |

Zhangjiagang City Bievo Machinery Co., Ltd. is located in a national level development zone - Zhangjiagang Economic And Technology Development Zone, covering area more than 8,000 square meters.We enjoy convenient transportation with Shanghai Hongqiao International Airport and Shanghai Pudong International Airport on hand.Which accumulated a great number of China's top technologists in the liquid beverage industry.We have complete system from designing, manufacturing, installation, training to after service.Our main product water production line, carbonated beverage production line . Fruit juice and milk production line ,3 to 5 gallons production line, daily chemical production line and so on.Plat and tube UHT device, CIP system.All the products are sold well.We devote ourselves to the development, research and production of liquid food and beverage filling and packing industry .

![]()

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

We make the price according to our comprehensive costing. And our price will lower than the trade company because we are manufacture.You will get competitive price and better quality.

Of course. We are the manufacture factory. More important, we put a high value on our reputation. Best quality is our principle all the time. You can be assured on our production completely.

After you place a order,the production handling time is about 30-45 days. We need 7 days to prepare all the stuff then 30 days for manufacturing.

Normally we use shipment to transprot the goods.It is about 25-40 days.It also denpends on which coutry and port you are. If there are some emergencies we can send the goods via air express, as long as you afford the traffic expense.

<1>Installation, debug

After equipment reached the workshop of customer, place the

equipment according to plane layout we offered. We will arrange

seasoned technician for equipment installation, debug and test

production at the same time make the equipment reach the rated

producing capacity of the line. The buyer need to supply the round

tickets and accommodation of our engineer, and the salary.

<2>Training

Our company offer technology training to customer. The content of

training is structure and maintenance of equipment, control and

operation of equipment. Seasoned technician will guide and

establish training outline. After training, the technician of buyer

could master the operation and maintenance, could adjust the

process and treat different failures.

<3>Quality guarantee

We promise that our goods are all new and not used. They're made of

suitable material, adopt new design. The quality, specification and

function all meet the demand of contract. We promise that the

products of this line could storage for one year without adding any

aseptic.