Suzhou orl power engineering co ., ltd |

|

Boiler Economizer CFB Boiler H finned tube Petroleum Economizer Natural Gas Industry For Power Station

Features: H/HH Fin Tube is formed on both sides of the straight channel, can achieve good blowing effect. The space is compact, the overall weight is reduced greatly, reduce cost; H type fin can flow space utilization effectively, keep the fin area and fin is larger than the thickness of the fin; can choose according to need any abrasion; fins are parallel to each other and independent, no effect of helix angle, which is convenient to ash.

"H" TYPE Finned tube can not only improve the windward side near the stagnation point speed,increase the axial purging,can increase the leeward surface reflux disturbance again.The velocity distribution characteristics make H finned tubes is not easy to dust.

Size and Materials:

| Description | H/HH Type Fin Tube |

| Bare Tube Material | carbon steel, alloy steel, stainless steel, non-ferrous alloys and nickel alloys. |

| Fin Tube Material | Carbon Steel,Alloy steel,Stainless Steel |

| Bare Tube Diameter(mm) | 25.4 ~1600 |

| Type | Welding |

| Length | 0<L≤ 12000 |

| Fin Pitch(mm) | 5 ~ 25.4 |

| Fin Height(mm) | 0.5 ~20.0 |

| Fin Thick(mm) | 0.5 ~3.0 |

| Application | H economizer,H evaporator,H superheater,H air heater and etc. |

Applications:

The main Petroleum Economizer Natural Gas Industry is Widely used for power plant, power station, etc.

1). Add the heat exchange area and reduce the number of tubes, also

increase the fume flow section area to reduce the fume speed and

abrasion.

2). H type fin tube can be made to double H type fin tube, high

rigidness to fit long tube row.

3). H type fin economizer arranged in line to make the space into

many small zones, averaged air flow to reduce the abrasion.

4). With straight channel to gain the best ash-blowing effect.

5). The compact structure to reduce the weight and reduce the

manufacturing cost.

Hot rolled seamless steel tubes and cold rolled seamless steel tubes for steam boiler systems

1.Implementation of the same standard, medium and low pressure boiler tube standards can be used. Hot rolled or cold-rolled (drawn) seamless steel tubes with high quality carbon structural steel.

2.The 2 main 10, 20 steel manufacturing, in addition to ensure the chemical composition and mechanical properties of things do pressure test, curling, flaring and flattening test.

3.Hot rolling in hot rolling, cold rolling (DIAL) in heat treatment delivery.

Competitive Advantage:

Quality control and management to the whole produce process,

including ingot smelting, hot-rolling, heat treatment, machining

and strictly final inspection prior to delivery.

Excellent product quality and service, competitive price, “in-time”

delivery

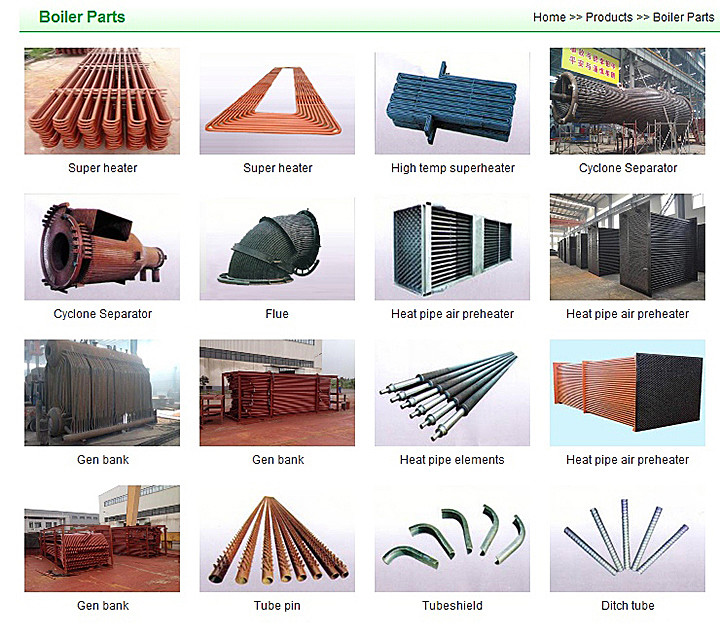

ORL Main products

Contact Information

ADD: No.11 East Renmin Road, Zhangjiagang City, Jiangsu, China

Phone:+86 0512-56770166

E-mail: info@orlpower.com

Website: http://www.orlpower.com