ZHANGJIAGANG HUA DONG ENERGY TECHNOLOGY CO.,LTD |

|

Verified Suppliers

|

|

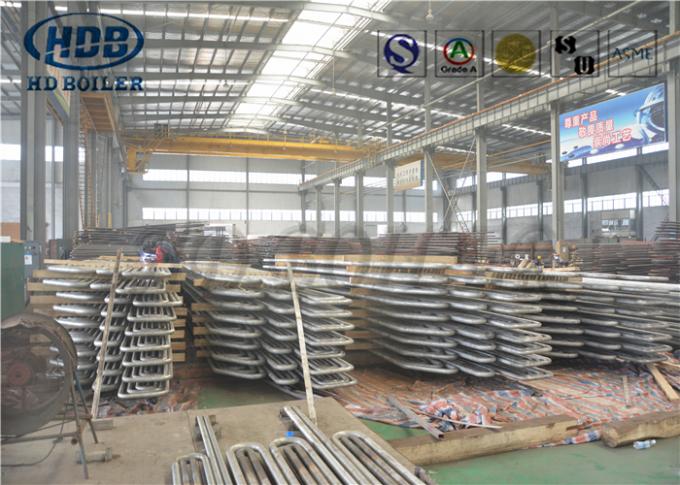

Carbon Steel Boiler Superheater Tube Superheater Coil For Power Industrial

Working Principle

Serpentine tube is that makes many twists and turns in a plane. As the convection heating surface of the boiler, such as economizer, superheater and reheater, etc., it normally adopts the structure of snake tube with horizontal and vertical arrangement.

Superheater is one of its applications. It is the part that heats the steam from the saturation temperature to the superheater by the boiler. It is also called the superheater. Superheater can be divided into convection type, radiant type and semi-radiant type according to heat transfer mode; According to the characteristics of the structure, it can be divided into serpentine tube type, screen type, wall type and wall type. They all consist of a number of parallel pipes and inlet and outlet manifold. Most industrial boilers do not have superheaters because many industrial processes and utilities require only saturated steam. Superheaters are generally installed in power stations, locomotives and Marine boilers to improve the thermal efficiency of the entire steam power plant.

Super heater types:

1. Radiant super heater: it is the earliest type of super heater

and it is located above or behind banks of water tubes to

protection them from direct flam or fire.

Parameters that increases the convection

a. Increasing the fuel-and air flow (combustion gas flow)

b. Increasing the mass flow rate of the steam

Radiation is mainly dependent on the flam temperature. as the steam flow rate increases the exit temperature become lower.

Radiant super heater

They are placed exposed to the heat source whcih requires the

improvement of metal temperatures.

Radiant and convetive super heaters and reheaters are used for high

temperature steam.

The accessory of high temperature radiant steam super heater in

boiler. It is made up of snake-like tubes (carbon steel, alloy steel or

heat-resistant steel, etc.) and collection boxes and other

supporting material. Tubes generally have φ32, φ38, φ42 or other

types of specifications, according to user's needs separately.

Reheaters

They are the sane as the super heaters but as their exit

temperature is a little bit less than super heaters and their

pressure is 20% -25% less than the super heater, they can stand

less quality material alloys.

Application:

Steam super heater is consisted of dense tube coils and is placed

in the flue under the tempearture 450ºC-1000ºC.

For power plant boiler capacity over 10Mpa, platen and coiled

superheater are usually adopted.

What are the differences of Superheater And Reheater?

| Type | Advantages | Disadvantages | Supporting method |

| Pendant-type | 1.Firm structural support | 1. Flow blockage by condensed steam 2. Needs slow restart to purge the water that accumulates in the bottom. | supported from above |

| Inverted-type | 1.Proper drainage of the condensed steam | 1. Lack the structural rigidity, especially in high speed gas flow | Supported from below |

| Horizontal -type | 1. Proper drainage 2. Good structural rigidity. | 1. They do not view the flam directly so they are mainly from the convective type | Usually supported in the vertical gas ducts parallel to the main furnace. |

Details

| Setting Information | |

| process | welding |

| structure | horizontal or vertical |

| material | carbon steel, alloy steel |

| tubes | φ32, 38, 42, etc. |

| size | customized |

| brand | HTEG |

| Warranty | 18 months |

Design structure

1. heating saturated steam, temperature up to 900 degree C.

2. high efficiency, >90%.

3. high speed heating.

4. design with stainless steel.

5. long design service life, 15 years.

Send us required technical data, such as steam capacity, presure, required temperature etc. We will design accordingly.

HD Boiler offers a best in class facility

For over 30years, Hua Dong Boiler has been consistently innovating and improving our boiler superheaters and reheaters.The improvements in bending,welding and design ensure our products meet both Euorpean and American standards, ensuring a relabile performance.