Zhangjiagang HuaDong Boiler Co., Ltd. |

|

Verified Suppliers

|

|

In order to improve the boiler efficiency, boilers are gradually developed into tubular boilers to increase heat transfer area. The pot water flows from the pot barrel to the lower box through the downward tube, and is distributed to each tube bundle by the box body. The water in these tube bundles continuously absorbs heat energy and collects into the upper box body and then flows back into the pot barrel. We call the upper and lower box body headers. Header is an important part of the boiler, which is divided into upper header and lower header.

The main function is to collet working fluids or redistribute working fluids to other pipelines through headers. That is, to collect, mix and distribute working fluids, so as to ensure the working fluids are evenly distributed and heated. Lower header, also called coke-proof box, is located on both sides of the grate and directly contacts with the burning coal seam. Its function is to cool the coking slag without bonding with the side wall.

Details

Header is not an independent component, but a part of water wall, economizer, super-heater and other components, that is, there are water wall header, economizer header, super-heater header. The function of header is to collect or distribute steam and water working fluid, reduce the pipeline of working substance transportation and connection, and reduce the numbers of holes in the drum, which is conducive to improving the safety performance of the drum. The lower header of the water wall near the grate on the both sides of the furnace wall prevents coking on both sides of the grate, so it is called the coke-proof box.

The header is actually a thick diameter tube connected with many heating surface pipes. It is made of seamless steel pipe and welded flat heads(end caps) at both ends. There are many holes in the box for welding or expanding the pipe. Both ends of the economizer tube and the superheater tube are connected to the header, and the lower end of the water wall is connected to the header. The upper end can be connected to the header, and a few pipes can be drawn from the head to the drum, or the upper end of the water wall tube can be directly connected to the drum.

Types

According to its location, there are upper header and lower header or inlet header and outlet header. According to the types of bundles collected, they can be divided into water wall headers, super-heater headers, economizer headers and so on.

Functions

Header is a pipe fittings for mixing working substances of boilers and ensuring uniform heating of working substances. Usually the furnace wall of industrial boilers is composed of rows of tubes(water-cooled walls), but the size of boilers is huge, and the structure is complex. It can not guarantee that the working substances in all tubes absorb the same heat. There are many differences in heat absorption in different parts. Installing headers can let the working substance in each tube converge here, and distribute to the next level of each pipe so as to reduce the thermal deviation so that the heat absorption, flow of the working fluid and cooling and thermal efficiency of the boiler are optimized and improved; in addition, the size, number and layout of the pipes in the upper, middle and lower parts of the boiler are different. The header is responsible for connecting each section to ensure smooth flow of working substances.

Features

The pressures and temperatures that headers have to withstand depend on the component to which they are connected. A header connected to an economizer or to water wall panels is subject to less severe requirements on the material than a header connected to superheaters or reheaters.

Depending on the temperature and pressure of headers, Vallourec supplies tubes in carbon steel to high-alloy ferritic steels such as T/P91 or T/P92, with sizes ranging from 88.9 mm to 406.4 mm.

Classification

| Material | Carbon steel,Alloy steel,Stainless steel. |

| Length | According to costumes requirements. |

| Temperature Range | 300℃~1500℃ |

| Diameter(OD) | 76mm~914mm |

Factory Workshop

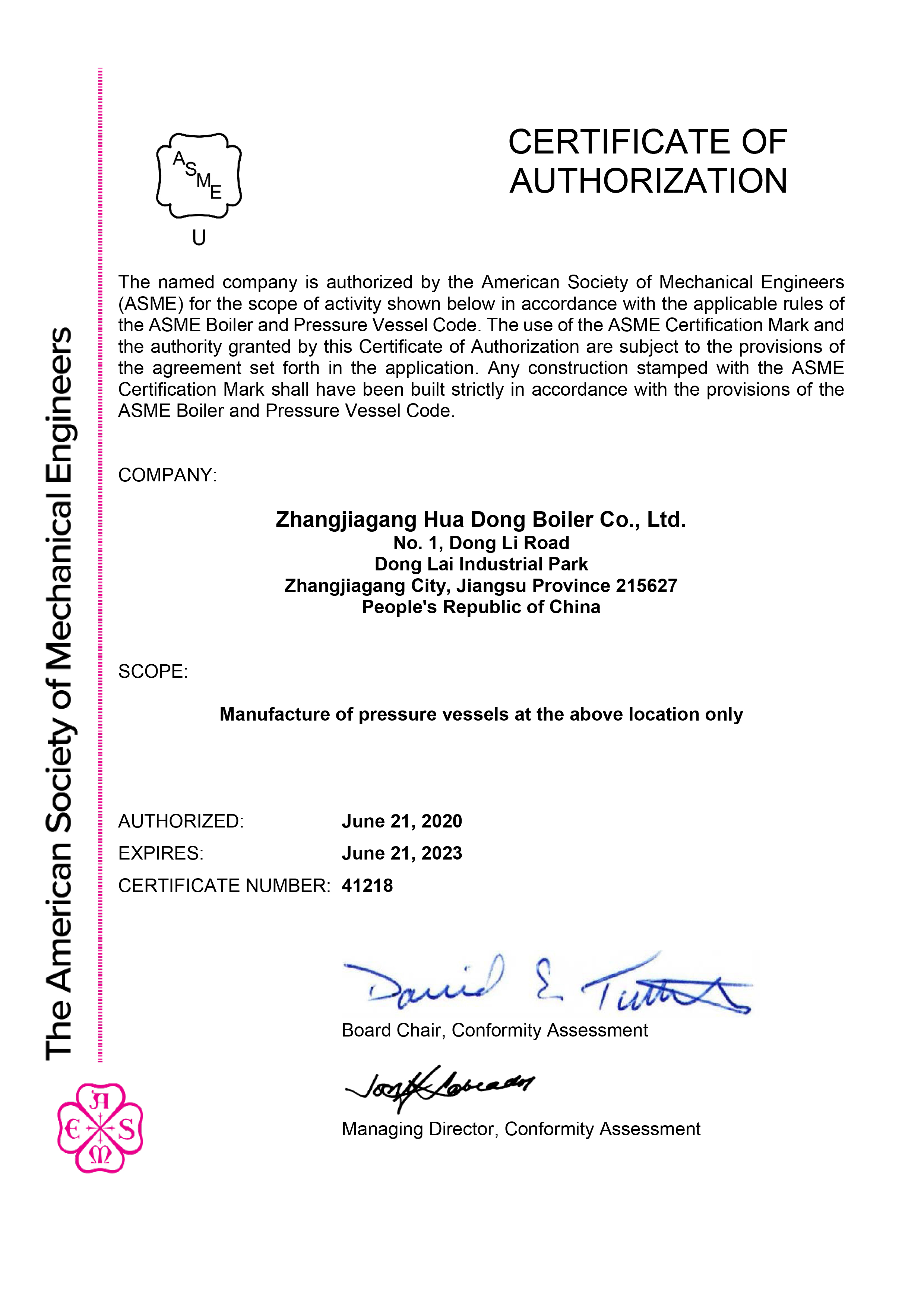

Certification