Zhangjiagang HuaDong Boiler Co., Ltd. |

|

Verified Suppliers

|

|

Power Plant Condensing Gas Boiler Water Wall Tubes / Water Wall Panels With Pins,ASME Standard

Product Introduce

Also known as barbed tube type water wall.It is the circular steel with certain length welded on smooth pipe surface according to the requirement, use pin to be able to lay firmly on water cooling wall fireproof coating, with regard to forming defend combustion belt, liquid discharge slag furnace slag pool and melting slag section, and cyclone furnace cyclone barrel.The water cooling wall of the inner threaded pipe is a pipe with single or multiple spiral grooves cut out on the inner wall of the pipe.The inner threaded pipe is used in the high heat load area or the water wall pipe section with high vaporization rate in the furnace of natural circulation boiler for dc boiler and subcritical parameter forced circulation boiler.When the working medium flows in the inner threaded pipe, strong disturbance occurs, which causes the water pressure in the soda mixture to the pipe wall, and forces the bubble out of the wall surface to be carried away by water, thus damaging the formation of the vapor film, preventing the deterioration of boiling heat transfer, and reducing the temperature of the water-cooled wall pipe wall.

Double-side exposure water wall refers to the water wall arranged along the furnace height in the furnace chamber space to absorb radiant heat on both sides.Used in large capacity boilers.Water wall materials are generally carbon steel.Part of the boiler pressure above 14 mpa is also made of alloy steel.Pipe diameter: natural circulation boiler generally used 51 ~ 83 mm;Multiple forced circulation boilers and dc boilers are generally used 22 ~ 60 mm.The water wall of a dc boiler is not necessarily vertical as in a natural circulation boiler, but can also be horizontally surrounded or in other forms.When the parameters are high, especially in the dc boiler, in order to prevent heat transfer deterioration in the high heat load area of the furnace, internal threaded pipe or spoiler is often used in the pipe

Product advantages

1. Guarantee the sealing of the furnace wall,reducing air leakage in combustion chamber .

2.Water Cooling in combustion chamber, so that in the case of

enhanced combustion is helpful to prevent coking.

3. Heat storage capacity is small, the combustion chamber heats up

fast, faster cooling, can shorten the boiler to startup and reduce

the furnace cooling time.

4. Appropriatly using the pipe wall, thereby significantly

reducing the boiler frame load, is advantageous for the suspension.

5.Compared with the light tube, improve the heat absorption

capacity of the pipe.

6.Improve the degree of the boiler parts of combination,

conveniently reduce the workload of the installation.

Specification

| Name | Studded water wall panel |

| Material | Carbon steel,Alloy,Stainless steel |

| Tube size | Φ38 - 76 mm, Customize |

| Standard | ISO , ASME |

| Model | Studded |

| Application | Istallable around the boiler combustion chamber |

Company Introduction

Established in 1985,Zhangjiagang Hua Dong Boiler Co.,Ltd.(trading as HD Boiler),produces power plant; industrial; waste heat; waste incineration; biomass; organic heat carrier and electric steam boilers. Coupled with a comprehensive range of heating surfaces, HD Boiler brings to the market a unique service including boiler design , fabrication, installation, maintenance and replacement of boiler pressure parts.

Quality Control

1. Fabrication area of 200,000 square meters

2. 150 Engineers

3. 600 Coded welders

4. 60 Licensed Inspectors(NDT Level-III instructors)

5. Class-A Licenses for Design and Manufacture Boiler

6. ISO 9001:2008 Quality System

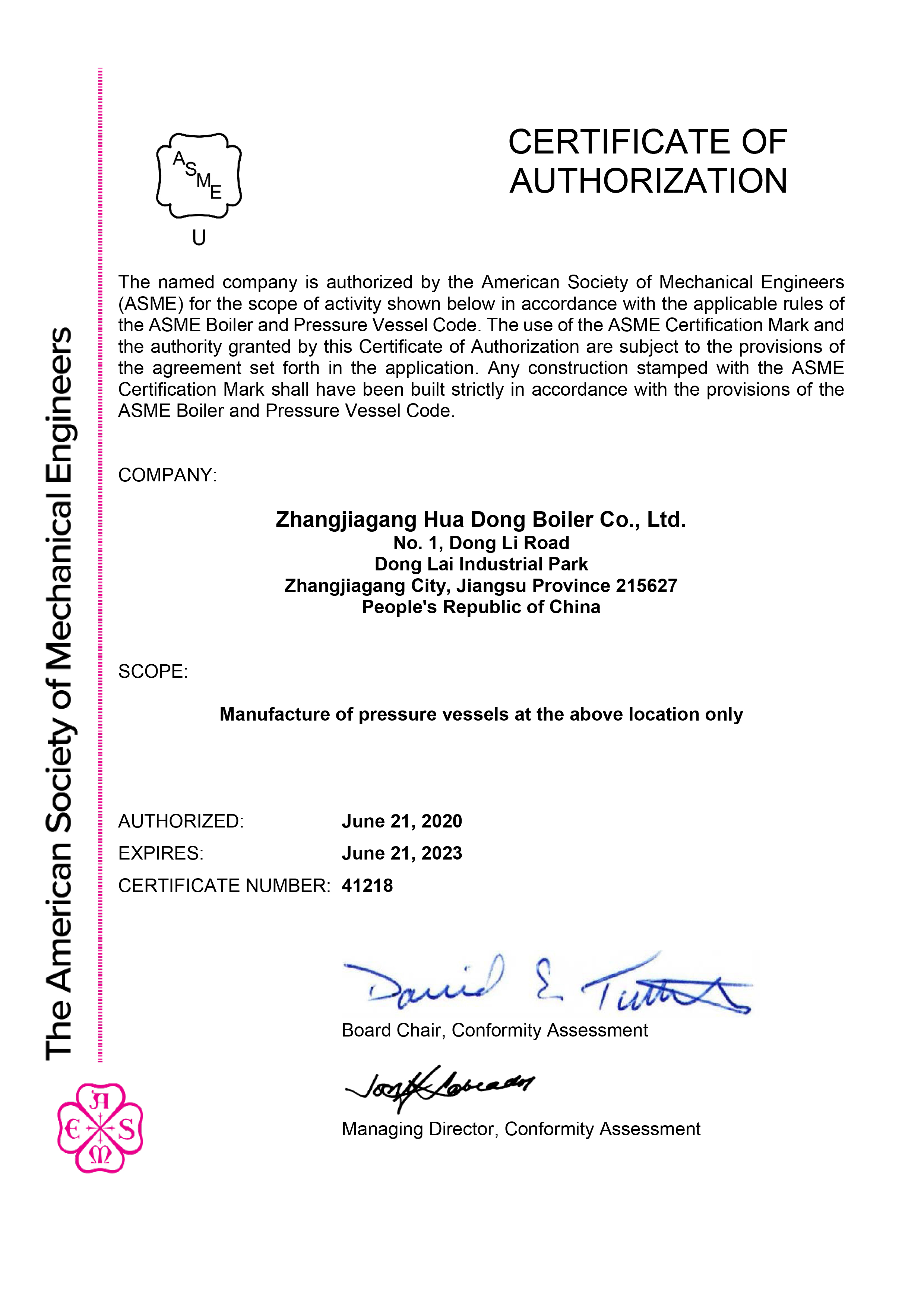

7. ASME Certificate of Power Boilers

8. ASME 'S','U' and NB stamp authorization