Zhangjiagang HuaDong Boiler Co., Ltd. |

|

Verified Suppliers

|

|

Nose arch rear water-wall panels export USA Utility boiler bending radius 16''

Introduction

HDB provides replacement boiler water walls, burner openings, inspection ports and doors for utility and industrial boilers. Recently completed projects include rear and sidewall replacement as part of a complete reheater replacement and the studded burner throat with bifurcated tubes pictured to the right. Inspection ports, camera ports, and access doors of any brand are also available.

Boiler water walls are membrane walls that are made of tubes welded together with or without a strip of metal in between. These walls form the enclosure of the coal combustion chamber. Water wall tubes are also referred to as the evaporator section; they contain water mostly in liquid form which gradually evaporates as it rises in the boiler.

Technical requirements

| 1 | Design and fabrication will be in accordance W/ASME SECTION I,2017 EDITION and approved shop standards. |

| 2 | Inspection will be performed by an independent authorized inspection agency,partial data reports will be issued and signed by an independent authorized inspection agency. |

| 3 | 100% of tube to tube pressure welds will be single shot RT inspected. |

| 4 | A sponge will be blown through each circuit to ensure no foreign substances are within the tubes. |

| 5 | All end preps for tube to tube welding should have a 37.5º±2.5º,Bevel with 0'' to 1/16'' Land. |

| 6 | Ends prepared for field welding will be protected with A coat of Deoxaluminate 2'' from the end and then capped and sealed with tape to provide an essentially water tight seal. |

| 7 | Stencil mark number,tube spec. and heat number on each panel. |

| 8 | All tube would be coated externally with one coat of 'with' primer paint.The inside surfaces will also be protected with a long term protection application such as ''cortected VPCI-609/609S''or equal after hydrotest and prior to shipment equals 0.5 ounces(14 grams)per tube. |

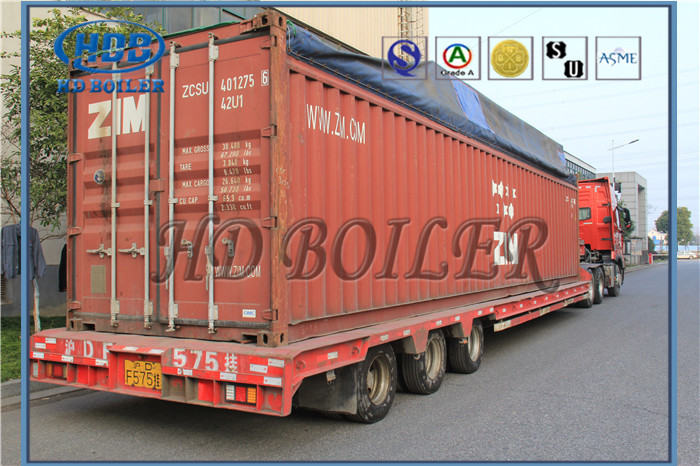

| 9 | All panels will be suitably prepared for ocean shipment and loaded into open top containeers to prevent damage during handling,shipment and storage. |

Application

The water wall is the main radiation heat surface, arranged inside the boiler chamber and proceeds the heat exchange directly with the high temperature flame. The convection tubes are the convection heat surface of the boiler, arranged between the boiler chamber outlet and the end surface and proceed the heat exchange directly with the high temperature fume.

Description

| 1 | Water wall panels are used in Waste Heat recovery boilers. We manufacture Water wall panels. These are fabricated out of carbon steel tubes to customers' drawings and specifications. Special care is taken for ovality and thinning at the bent portion, during fabrication. |

| 2 | We are manufacturing and supplying a comprehensive range of Waterwall Panels. The tubes offered by us are known to withstand a great internal pressure as a continual strip of fin material is wound spirally on the tube. These tubes are known to provide heat uniformly that result in an increased heat output. |

| 3 | The main function of water wall panels in boiler is to absorb the heat generated by high temperature flame or flue and to generate steam or hot water in tubes, hence to reduce the temperature in the chamber. |

The accessories and detailed information

A waterwall in a boiler is any furnace wall that is comprised of refractory and tubes in a water-tube boiler. The tubes are evenly spaced and generally connectto headers which in turn are connected back to the main generating bank of the boiler.

Transoprtation