Zhangjiagang HuaDong Boiler Co., Ltd. |

|

Verified Suppliers

|

|

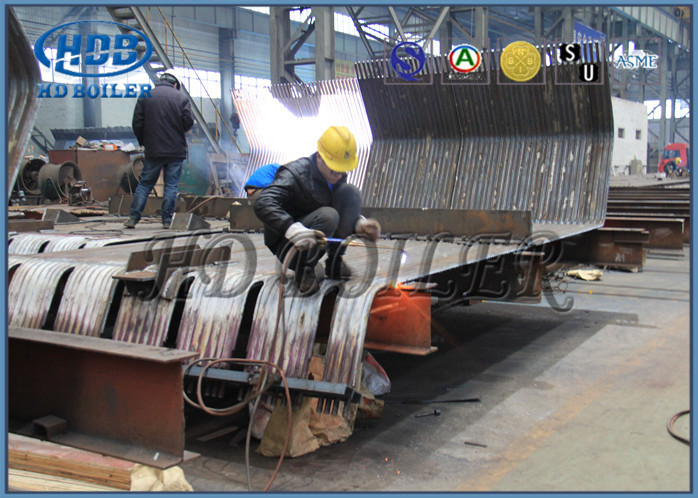

Panel bending turning radious press forming boiler water wall panel 100% penetrant inspection

Description

| 1 | Membrane walls were originally introduced for land power stations and are being increasingly used in marine boilers. |

| 2 | Originally, experience gained when making the lower parts of furnaces sufficiently tight to hold liquid ash, proved that this could be done by welding in steel strips between the floor tubes. |

| 3 | Further development of this technique resulted in completely gas-tight furnace wall panels being constructed by welding together either finned tubes or normal tubes with steel strip interspaced between them. |

Basic panel characteristics

| -Max.length of a membrane wall:20000mm |

| -Diameter of tubes:Customized |

-Width of fin:Customized |

| -Welding type:submerged arc welding |

| -Min.bending radius:Press forming,lower than D |

Relevant data

| 1 | Calibraion machine which ensures straightening of strip steel. |

| 2 | Bending of membrane walls is provided the panel bending machine. |

| 3 | If necessary,membrane walls are heat treated in an electrical furnace. |

Corrosion protection

| 1 | Improving boiler performance and reliability is an ongoing challenge for boiler operations maintenace teams. |

| 2 | In addition to our shop cladding facility we provide onsite weld overlay services to our global client base, protecting boilers and components from corrosion and erosion by applying our weld overlay solutions, often in harsh and challenging environments. |

| 3 | With continued focus on safety,quality and ever demanding schedules,our highly skilled teams have executed numerous projects on waste-to-energy and biomass plants,reducing maintenance costs by providing an effective boiler protection. |

Function

| 1 | Water walls are used in water tube boilers to contain the heat of the furnace and reduce the amount of refractory material required. |

| 2 | They also contribute to the evaporation rate by receiving radiant heat; indeed, in radiant heat boilers the water walls provide the bulk of steam generation. |

Advantages

| 1 | The walls for the entire furnace and, if necessary, the convection sections can be prefabricated in the shop. |

| 2 | They are stronger and more gastight than any other type. |

| 3 | Maintenance is low as refractories are practically eliminated. |

| 4 | Water washing of furnace walls and tube banks is facilitated. |

| 5 | The gas-tightness of the furnace eliminates the possibility of corrosion of the outer casings by corrosive gases (see figure below). |

NDT and inspection services

| Our level II and/or level III QA Inspectors will provide a comprehensive report for existing overlay to establish scope requirements or on the completion of a weld overlay project. |

Product