Zhangjiagang HuaDong Boiler Co., Ltd. |

|

Verified Suppliers

|

|

Power Station Boiler Header Heating Power Chemical Oil Chemical Industry boiler unit SGS

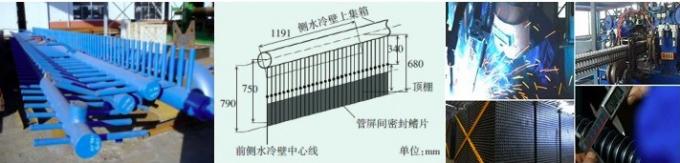

The boiler headers have water wall header, superheater header, economizer header and so on, it acts as collection, mixture, re-distributing working medium. From the structure, it can be classified as the end cover type (end closure) and necking down type.

The critical point to manufacture the end cover is the welding process. We adopt the advanced manufacture process, the complete large size device and mature technology. Especially the welding of the end cover with the header, we adopt the auto submerged welding, this welding method is featured with high manufacturing efficiency, good quality, artistic appearance and safe and reliable operation.

Technical parameters of customer design boiler pressure parts header for CFB boiler

| Diameter(OD) | ¢76mm~¢914mm |

| Length(Max) | 23000mm |

| Temperature(℃) | 300~1500 |

Material

1. Carbon steel:20G,SA-106B,SA-106C,etc.

2. Low-alloy thermal resistant steel:15CrMoG,12Cr1MoVG,SA-335P12,SA335-P22,etc.

3. Middle-alloy thermal resistant steel:SA-335P91,etc.

4. Special material(ultra-supercritical):SA-335P122,SA-335P92,etc.

Features

1. Strength calculation report with applied materials information;

2. 100%NDT(non-destructive inspection) report of steel plate, tube

and welding rod;

3. 100%X-ray inspection report (welding seam): to ensure the

quality of the entire boiler;

4. Hydraulic test report: ensure the standard working pressure and

safet

Workshop

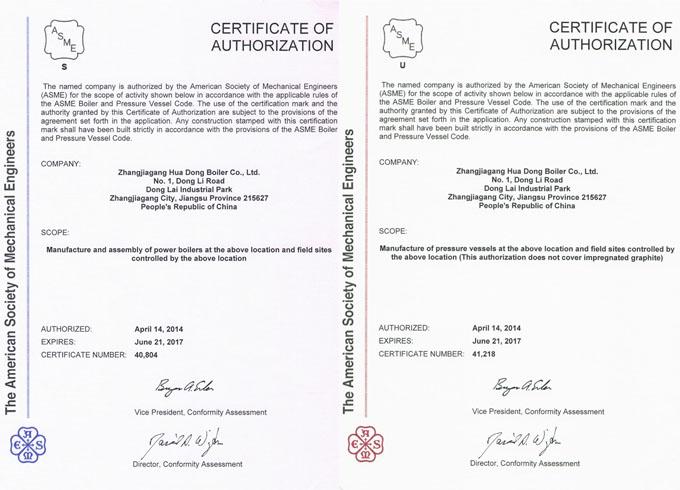

Certifications

Competitive Advantage

Quality control and management to the whole produce process,

including ingot smelting, hot-rolling, heat treatment, machining

and strictly final inspection prior to delivery.

Excellent product quality and service, competitive price, “in-time”

delivery