Hebei Greens Building Material Technology Development Co.,Ltd |

|

Fiber Cement Board Machine| calcium silicate board making machine

calcium silicate boar products and properties:

1. year output provided:

million sqm one year 3-5million sqm one year.

2. main materials:

silicon materials: quartz powder, diatomite, fly ash, etc.

calcium materials: hydrated lime powder, cement, calcium carbide

mud, etc.

3. the power supply:

A mechanical and electrical capacity of 700-1200KW or so explosive filling, high and low voltage switch gear.

4. calcium silicate board main dimension:

standard size: 1220*2440mm 1200*2400mm

Thickness: 4-30mm

suspended ceiling: 595*595/600*600/603*603mm

Density: 900-1200kg/m3

Edges: square /beveled

Installation: match with ceiling grids

calcium silicate board production line machine:

Calcium silicate board is a new type of waterproof board. It has lots of advantages such as sound insulation, fireproof, waterproof, mouldproof, heat insulation, light, etc.

The main raw materials are quartz powder(pulp), cement, hydrated lime powder, asbestos,

paper pulp, wollastonite and others( mica, glass fiber, etc.)

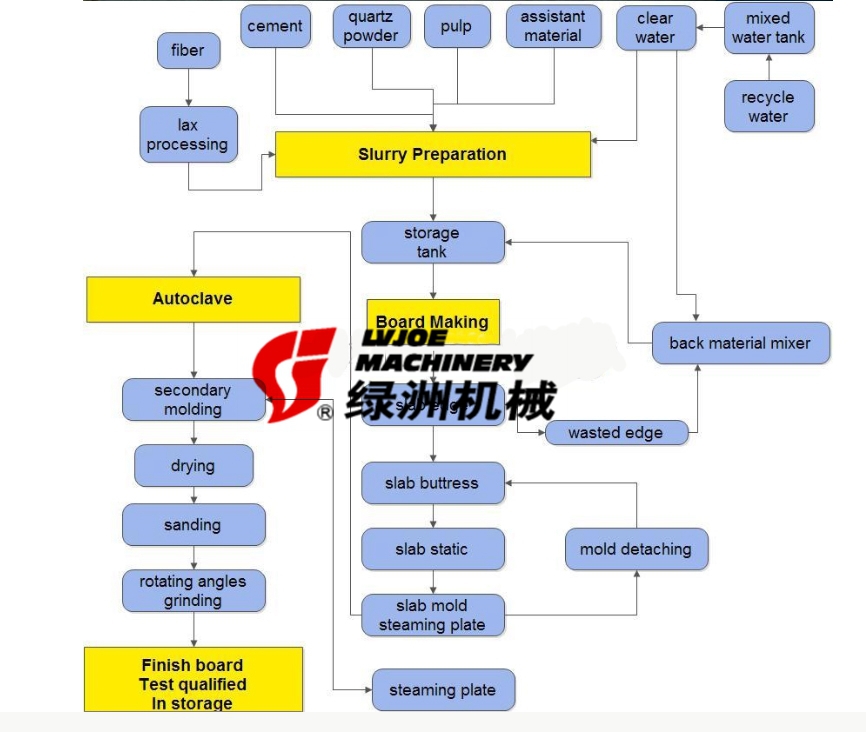

The production process of calcium silicate board:

1. Quartz plasma processing

2. Paper processing

3. Pulping

4. Seperation, mixing and slurry control

5. Molding, answer the billet and stacking

6. Maintenance and stripping

7. Autoclaved maintenance

8. Drying

9. Sanding, edging and chamfering

Standard calcium silicate board dimension:

Length: 2400-2440mm

Width: 1200-1220mm

Thickness: 4-30mm

It adopts slurry flowing method or hatschek method. We will provide one-stop service.

The flow chat of calcium silicate board production line

calcium silicate board application:

widely applied in the suspended ceiling system of business building, entertainment facility, supermarket, hotel, restaurant, hospital, theater, warehouse, apartment building and so on.

1) The machine guarantee1 years except the easy worn parts such as bearings,

electric buttons.

2) Our company could dispatch professional engineer to buyer’s factory when the machine arrive at the

destination.

3) Our engineers will train the buyers' worker to operate the machine and after

you master the machine then pay us the installation and commissioning payment.

4) In order to ensure the machine working well, each year we will send engineer

to check and develop the technology.