Changzhou Bextreme Shell Motor Technology Co.,Ltd |

|

Verified Suppliers

|

|

12v 24vdc DC mini Submersible water pump Brushless Small Circulating pump

2 series electronic water pump is a low energy consumption and high efficiency water pump launched by our company. The characteristics of this pump are: small size, light weight, compact structure, wide application environment, and platform development design.

constant power:

Power supply voltage change between DC12V ~ 18 v, and the water

pump power basically remain unchanged.

The voltage between the DC24V ~ 32 v change, pump power basically

remain unchanged.

overvoltage protection:

18 v, pump power supply voltage is higher than the pump into the

outage protection, voltage return to normal, the pump back tonormal

work. Water pump, power supply voltage is higher than 33 v pump

into the outage protection, voltage return to normal, the pump back

to normal work.

Stall protection:

When the pipeline has caused by impurities in the water pump

blocked binding, water pump stop running (water pump motor after

the restart 20 times in a row, if the state is still not eliminate

locked-rotor pump stop working), locked-rotor state after

eliminating the water pump power to restart the pump recovery was

often work.

Dry running protection:

Not connected to the circulation medium in pipeline, water pump

speed reduction operation, running, shut down after 15 min after

downtime need power heavy qi; The dry operation of the water pump

in the stage of reducing the speed, the water supply is restored,

the water pump returns to normal work.

■ Technical description (related parts in contact with the liquid)

Pump head housing: Die casting aluminum alloys

Impeller: PPS+GF

Shield cavity: PPS+GF

Shaft sleeve: carborundum composite materials

Shaft: stainless steel(3CR14) shaft

Magnet housing: PPS plastic capsulation

Seal ring: EPDM

EMC: Grade 3

Noise:≤60dB

■ Driving device (Including motor)

Driving rotor: PPS plastic capsulated magnet

Screws and nuts: SUS 304 stainless steel

Driving Motor : brushless DC motor

Motor wire frame :PPA GF

Pump housing: Die-casting aluminum case with sandblasting and anodizing +PE powder coating..

Bracket: steel

Bracket hoop: US 304 stainless steel

Waterproof based on IP68 rating (en60529)

Connector model: 325304061AAH (matched Plug 325304061AMH)

Nozzle diameter:41mm (1.61 inch)

■ Mounting instruction

OWP-BL43-402CAN series pumps are centrifugal pumps which require pre-filled,

The pump installed in the lowest position of the system to ensure that the impeller is always immersed in the liquid, or pre-filled the pump before power on .

1: Pump should not be dry-running, even though it can dry-running for 15 minutes (after 15 minutes dry-running, it will automatically stop), Dry running will makes noise, also increasing abrasion to the shaft and shaft sleeve.

2:Use the recommended diameter pipe connecting the pump inlet, if you use a smaller diameter hose pump inlet, Due to the negative pressure in the pump, the outside air easier enter to the pump through the pipeline, it will make the pump performance degradation, and also the air bubbles make damage to the pump.

3: As viewed from the pump inlet direction, the impeller rotates clockwise (see the arrow on the outlet port).

4: The pump can be installed vertically or horizontally mounted (see figure 1 ) When installed vertically, the outlet port should be upward .

5:In order to avoid the dry- running (air get stuck in impeller),the water pump outlet port should be vertical or in the upper of the impeller. (see figure 1 )

6: The connected pipe should be vertically mounted (or no elbow in 20cm )to make the air discharged easily, the outlet pipe should not be used less than 90 degrees elbow (see figure 2).

7: Can't use the seawater or other heavy pollution with big grain impurity liquid as the liquid medium .

figure 1 figure 2

■ Temperature parameter

Medium liquid temperature: -40℃ to +85℃ (-40°F to + 185°F)

Working ambient temperature: -40℃ to +85℃ (-40°F to +185°F)

Storage temperature: -40℃ to +70℃ (-40°F to +158°F)

(up to 100 ℃, but it will shorten the service life)

■ System pressure

-0.2 to 2.5 bar ( 100℃ (212°F).

The service life is more than 20,000 hours based on the rated voltage and 36℃(86°F) ambient temperature.

■ Voltage range

Rated 24V water pump, workable range 18V - 32V

Although the motor can be used in a wide range of voltage and temperature, but excessive or too low voltage and temperature will affect the service life of the motor, the pump can not be exposed to thermal radiation ambient.

Medium liquid: liquid mixture (Water with below 60% glycol)

■ Electrical parameter

Working Voltage (VDC) | Rated power (W) | Rated flow (L/H) | Dimensions (mm) | Weight (g) |

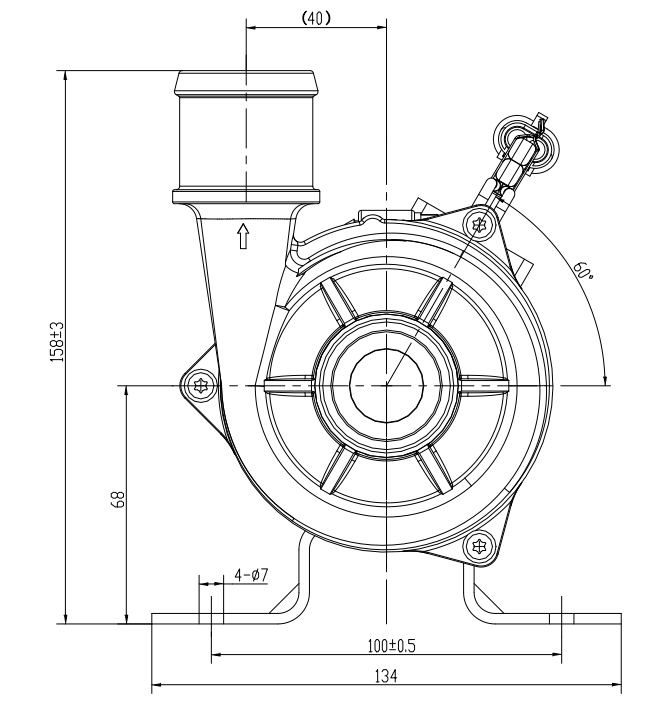

| 18V-32V(24V) | 240W | Q=2400L/H, H=17m | 185*134*158 | 2200g |

Attentions

1. Working ambient temperature:-40℃--120℃, should try to avoid close to three-element catalytic, gas discharge pipe system and engine during the installation, ensure the working environment temperature.

2.The installation position of the water pump should as much as possible close to the low water level , to extend the service life of the pump.

4. Please use the pump far from the dusty environment, the dust is harmful to reduce the service life

5. Pay attention to the purity of the water, avoid to jam and impeller-blocked to reduce the service life of pump

Performance parameter

■External dimension