DEZHOU FEITENG ROAD CONSTRUCTION EQUIPMENT CO., LTD. |

|

Verified Suppliers

|

|

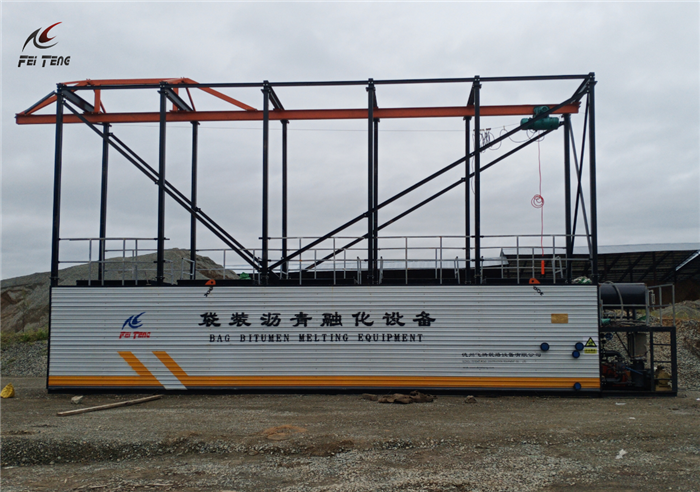

Steel Plate 5 Tons Per Hour Bitumen Melting Machine With High Density Rock Wool Insulation

Description

YDLR bitumen melting equipment is developed by us which uses diesel oil burner as heating device to heat, melt, dump and dewater bitumen.

Bag bitumen melter components

The equipment mainly consists of melting tank, lifting system, diesel burner, exhaust flue heating system, thermal oil heating system, bitumen pump, pipe system and electric control system.

Working principle

This equipment is specially designed for the melting and heating of 1 ton bag asphalt. The shape is square tank. The top of the equipment is equipped with a electric hoist. The bag asphalt is lifted by the hoist to the feeding port at the top of the equipment. The bottom bag is cut by knives, then the asphalt block in the bag will be taken out and dropped into the equipment through the feeding port to be heated. There are 5 feeding ports, each port will be with one movable lid for insulation and rain proof

Features

1. The bag lifting operation is made by the electric hoist system.

2. The heating required to melt the bitumen is provided by heat conducting oil and exhaust flue.

3. The equipment consists of upper and lower two rooms, the upper one for melting the bitumen blocks, cutting them into small pieces. The lower room is mainly for increasing the heating temperature of the bitumen till reach to (110 degree), then Bitumen outlet pump will transfer the bitumen outside to be ready for use if extend the heating time can be obtained a higher temperature to (160 degree).

4. Easy to put the bags inside the equipment without any platforms with high efficiency.

5. No need for trolley or any wrench to carry the bag inside the plant.

6. Simple structure, compact design, easy to maintain.

7. Environmental protection and good, enclosed structure, no pollution.

8. Facilitate the relocation: container structure assembled quickly.

| Item | Unit | Parameter | Remark |

| Product rate | t/h | 5 | Air over 25 degree |

| Diesel consumption | kg/asphalt per ton | 6-8 | |

| Asphalt output temperature | degree | >110 | |

| Asphalt storage capacity | m3 | >30 | |

| Thermal oil working temperature | degree | 200-250 | |

| Asphalt pump flow rate | m3/h | 16 | |

| Total power | kw | 15 | |

| Outer size(length*width*height) | m | 11.9×2.2×2.55 | Shipping size |

Our advantages

Our factory, DEZHOU FEITENG ROAD CONSTRUCTION EQUIPMENT CO., LTD., specializes in designing and manufacturing asphalt equipment, mainly including asphalt melting equipment for drum/box/bag packing, asphalt tank, asphalt emulsion equipment and asphalt sprayer, also we have the big advantages as below,

1. Independent design and professional manufacturer.

2. Production capacity over 200 sets per year.

3. All equipments with compact structure, suitable for container load.

4. Select premium steel with high quality.

5. Complete production control with detailed record and video.

6. Our factory had passed ISO system authentication, including ISO9001, ISO 14001, OHSAS18001.

7. We manufacture our standard equipment, also welcome OEM and ODM.

Our service

Our factory, DEZHOU FEITENG ROAD CONSTRUCTION EQUIPMENT CO., LTD., specializes in designing and manufacturing asphalt equipment, you may get as below,

1. Design drawing as your requirement

2. Equipment solution as your real condition

3. Quality equipment as your order

4. Quick response as your time

5. Fast delivery as your demand

6. Complete warranty as your expect

Quality product, quick response and cost saving.

Delivery and shipping

1. Production time around 5-15 days per set

2. Suitable for 40 HQ container loading

3. Trade terms EXW, FOB, CFR, CIF

After sale service

1. Warranty one year

2. Online support service and video technical support

3. Free spare parts

4. Field installation, commissioning and training, field maintenance