YANTAI BAGEASE PACKAGING PRODUCTS CO.,LTD |

|

UV Resistant Preserve Silage, Hay, Maize Protection Wrap Film Agriculture Silage Grass Bale Pack Silage Stretch Film

Plastic Hay Bale UV Resistant Grass Bale Silage Protection Wrap Film Agriculture Silage Grass Pack Silage Stretch Film

Please inquiry us

Bagplastics@vip.163.com

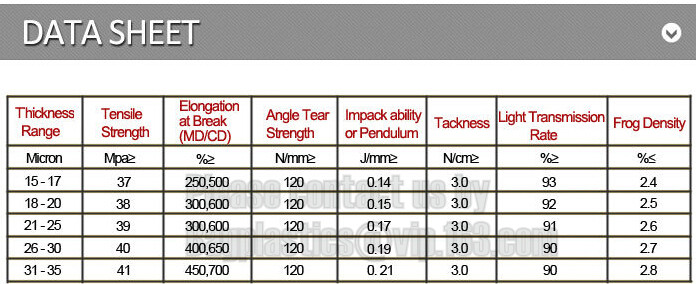

Date sheet

| Projects | Unit | 250mm*25µm | 500mm*25µm | 750mm*25µm | |

| Elongation | Lengthways | % | ≥450 | ≥450 | ≥450 |

| Lateral | % | ≥700 | ≥700 | ≥700 | |

| Tearing Stretch | Lengthways | g | ≥200 | ≥200 | ≥200 |

| Lateral | g | ≥350 | ≥350 | ≥350 | |

| Tensile Stretch | Lengthways | Kgf/cm2 | ≥300 | ≥400 | ≥580 |

| Lateral | Kgf/cm2 | ≥280 | ≥280 | ≥280 | |

| Prestretching | % | >350 | >350 | >350 | |

| Sticky Limit | gm/25cm | 200~250 | 200~250 | 200~250 | |

| Colour | WHITE,BLACK,LIGHT GREEN,GREEN | ||||

| Outdoor Storage Period | 12 MONTHS Please inquiry us Bagplastics@vip.163.com | ||||

High Quality UV Resistant Agriculture Grass Bale Plastic Silage Wrap Film

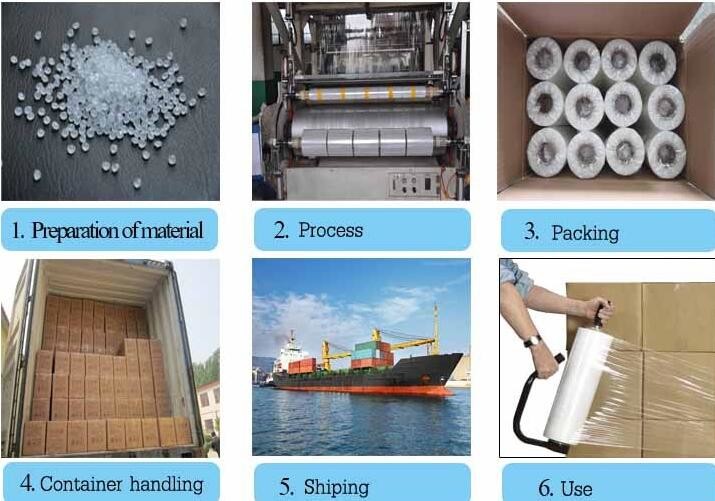

1. About Us

We are the professional manufacturer specializing in LLDPE silage film since 1990. Bagease.cn

We have various production lines, great production capability, which make sure 250 tons per month.

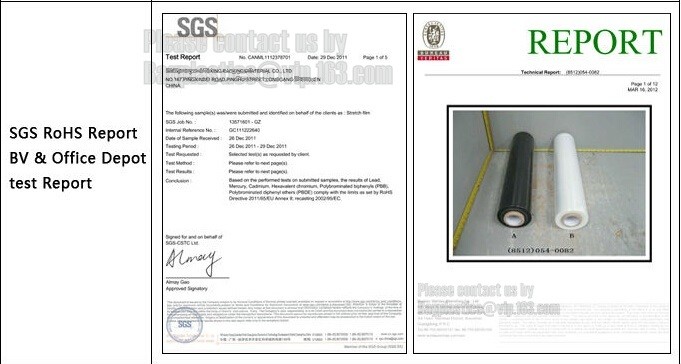

Our products have passed SGS certificate.

We have established a mutually longterm business relationship with customers from Japan, US, New Zealand, Australia, Finland, Norway and so on. Please inquiry us

Bagplastics@vip.163.com

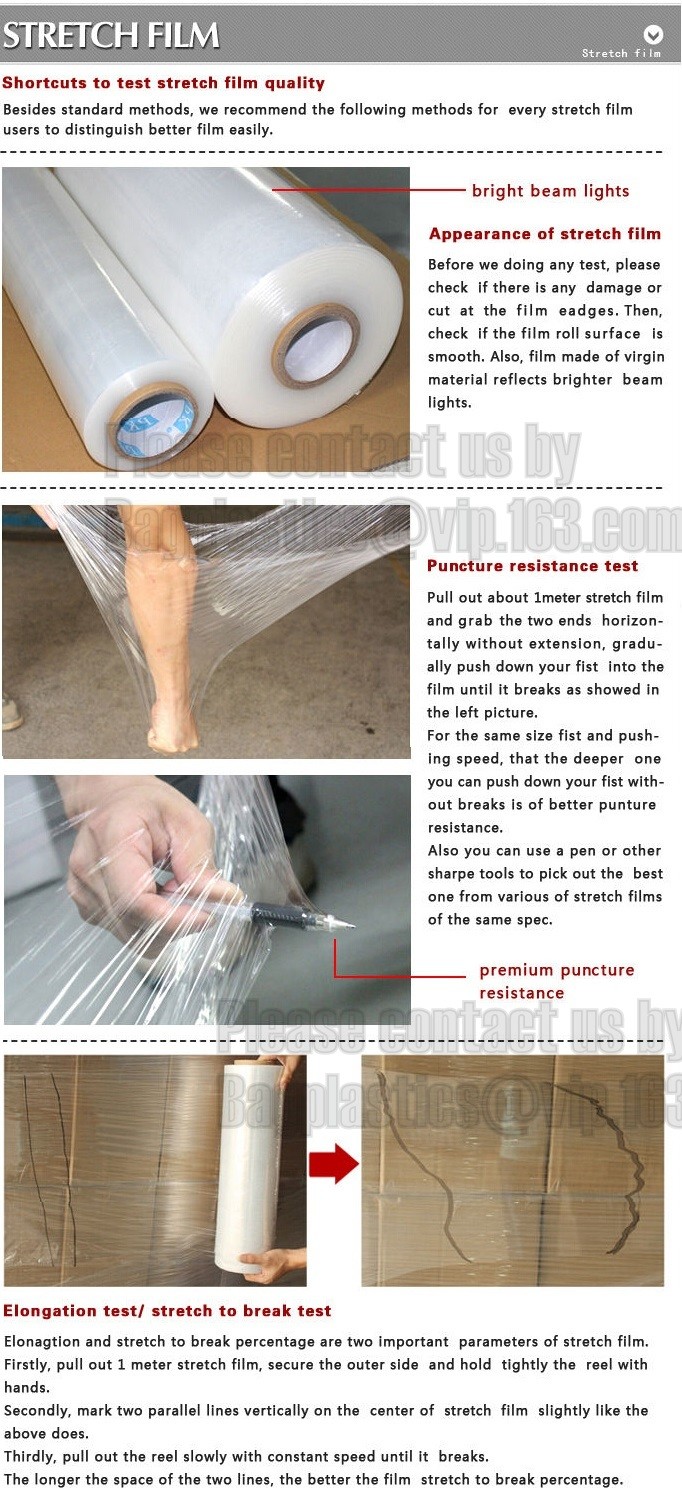

2.Features of Silage film

1) High tack plus high puncture and tear resistance

2) High load retention (for bale integrity)

3) Guaranteed to withstand the harshest climates

4) Made to International Quality Standards for extreme conditions

5) More bales per roll. Greater wrapping efficiency

6) Provides an airtight and weatherproof shield

7) 12 month guarantee against UV degradation

8) Stretch level at approximately 300%

9) Good thickness distribution in the film at 25 microns optimum

Please inquiry us

Bagplastics@vip.163.com

3. Silage film Instructions

1) Do not overstretch the film,ensure the maximum stretch rate of 70% is not exceeded.

2) Apply a minimum of 4 layers at 50% overlap

3) Inspect the bales regularly and repair any holes or other damage immediately with an approved repair tape.

4) Store wrapped bales on ends only

5) Do not roll the wrapped bales as damage may occur

6) Ensure no chemicals come into contact with the films as this will cause premature breakdown

7) Use only approved baling twine.

8) Prevent roll damage as this will cause the film to break when wrapping

9) Keep livestock away from wrapped bales

10) Store bales clear of vegetation that can damage the film

11) Inspect and repair any damage caused by rodents or other animals.

12) Store unused film in a cool,dark and dry area.

13) This film will last for a minimum period of 12 months from time of wrapping when used in accordance with the bove instructions.

14) Take care handling this product as the weight exceeds 20kgs.

Please inquiry us

Bagplastics@vip.163.com

4. Silage film data sheet

| Projects | Unit | 250mm*25µm | 500mm*25µm | 750mm*25µm | |

| Elongation | Lengthways | % | ≥450 | ≥450 | ≥450 |

| Lateral | % | ≥700 | ≥700 | ≥700 | |

| Tearing Stretch | Lengthways | g | ≥200 | ≥200 | ≥200 |

| Lateral | g | ≥350 | ≥350 | ≥350 | |

| Tensile Stretch | Lengthways | Kgf/cm2 | ≥300 | ≥400 | ≥580 |

| Lateral | Kgf/cm2 | ≥280 | ≥280 | ≥280 | |

| Prestretching | % | >350 | >350 | >350 | |

| Sticky Limit | gm/25cm | 200~250 | 200~250 | 200~250 | |

| Colour | WHITE,BLACK,LIGHT GREEN,GREEN | ||||

| Outdoor Storage Period | 2 YEARS Please inquiry us Bagplastics@vip.163.com | ||||

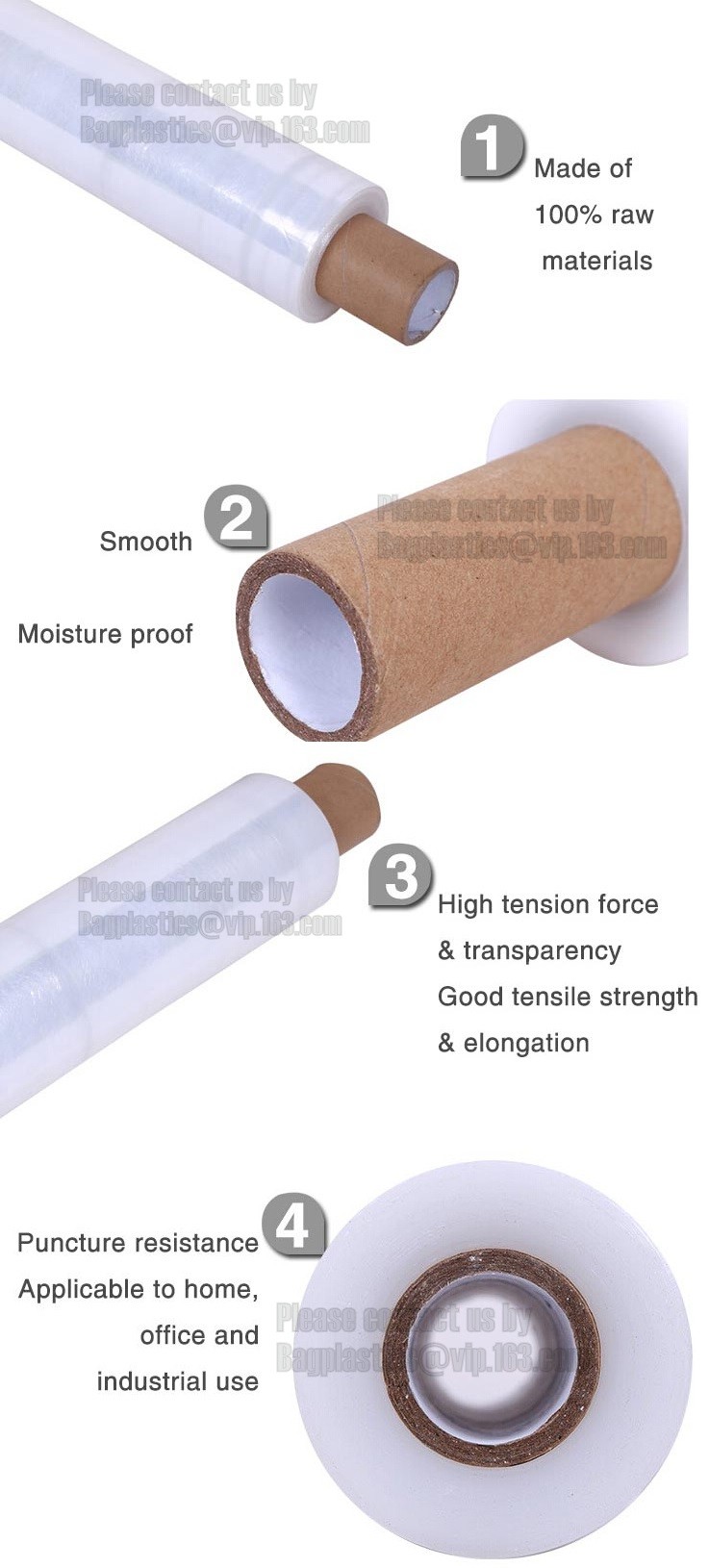

5. We guarantee :

Please inquiry us

Bagplastics@vip.163.com

1) 12 months guarantee on the bale.

2) No recycled raw materials are used.

3) Minimum of 1500 metres per roll.

4) Silage film is at least 25 microns thick.

5) Silage film comes on a light cardboard core wrapped in a plastic bag.

6) Any queries will be handled in a speedy and efficient manner.

If you are in need of our products, please feel free to contact us!

Please inquiry us

Bagplastics@vip.163.com

We will reply you within 24 hours!

Specification:

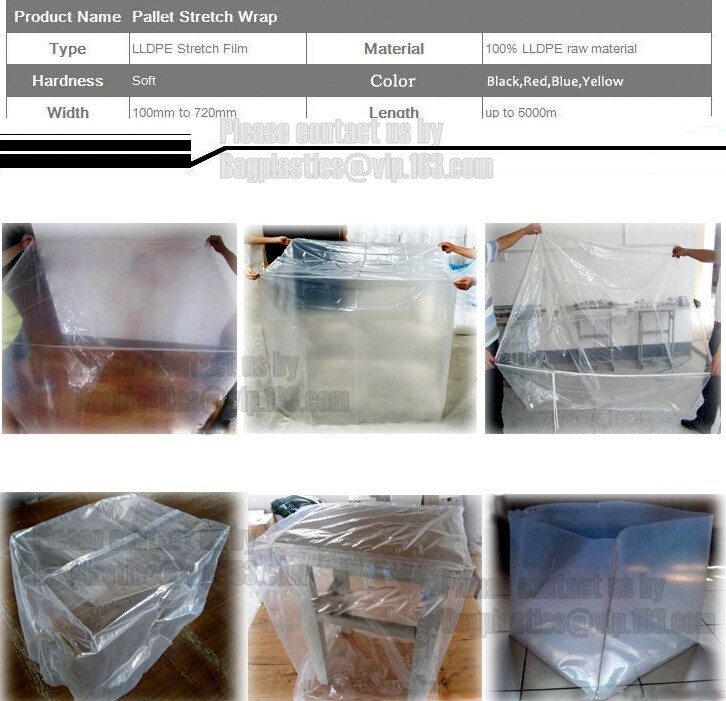

| Type: | LLDPE |

| Usage: | Agriculture |

| Hardness: | Soft |

| Processing Type: | Blown |

| Thickness: | 20-35 microns |

| Raw Material Supplier: | DOW Chemical |

| Plastic Core Diameter: | 76mm (3") |

| Grade: | Machine Grade |

| Width: | 250mm,375mm, 500mm, 750mm |

| Length: | 1500m, 1800m |

| Color: | Green/White/Black |

Please inquiry us

Bagplastics@vip.163.com

Product Model Details:

| Product No. | Color | Size | Weight/Roll | Rolls/Pallet | Loading(Rolls) | |

| 20 feet | 40 feet | |||||

| AGRI W500 | White | 25mic*500mm*1800m | 22.0kg | 56 | 560 | 1120 |

| AGRI W750 | White | 25mic*750mm*1500m | 28.0kg | 50 | 500 | 900 |

| AGRI G500 | Green | 25mic*500mm*1800m | 22.0kg | 56 | 560 | 1120 |

| AGRI G750 | Green | 25mic*750mm*1500m | 28.0kg | 50 | 500 | 900 |

| AGRI B500 | Black | 25mic*500mm*1800m | 22.0kg | 56 | 560 | 1120 |

| AGRI B750 | Black | 25mic*750mm*1500m | 28.0kg | 50 | 500 | 900 |

Please inquiry us

Bagplastics@vip.163.com

Features:

Please inquiry us

Bagplastics@vip.163.com

1)With good mechanical, easy for strapping silage.

2)With high adhesion, forming an oxygen-detested environment inside the package.

3)Strong stength including stretch, tear resistance and puncture resistance.

4)Very flexible and low light-through rate, avoiding heat accumulation.

5)Stable, resistant to sunlight(UV)damage, long usage period and bundle up more than one year.

6)You can get a reasonable price and high quality from our factory.

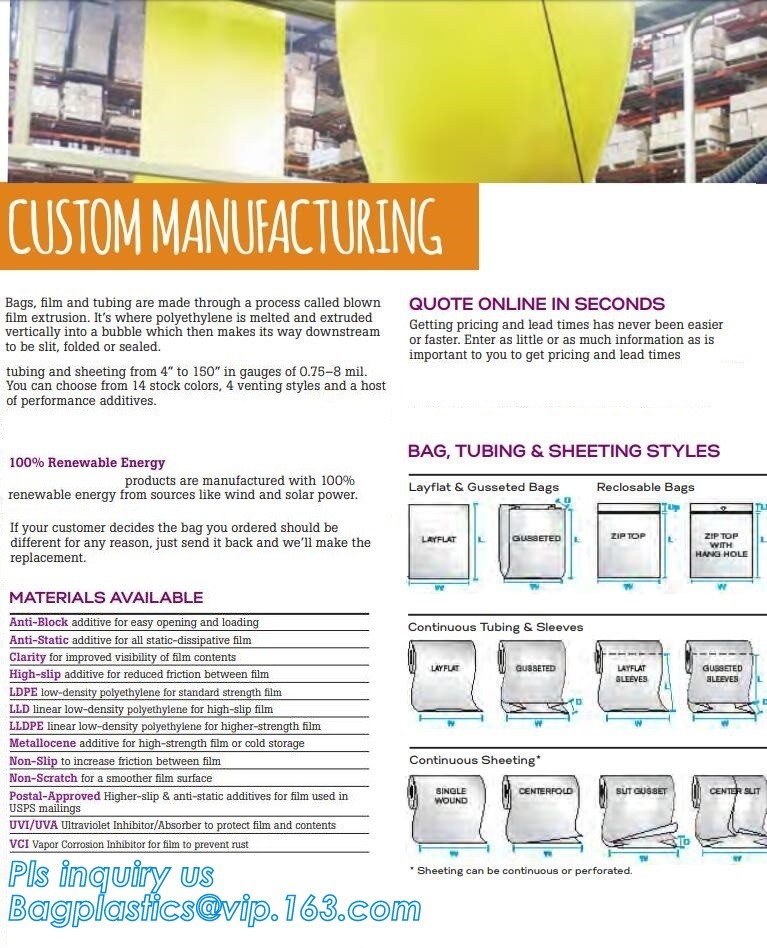

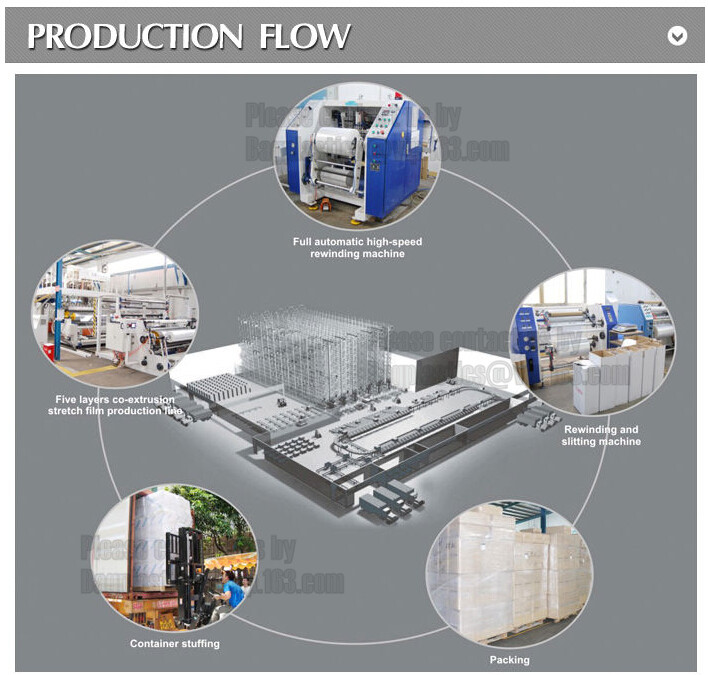

Advanced 5-layers co-extruded blown film line from Europe with globally leading technology, large-scale production factories, complete QC test process, and Intelligent color matching system, supply excellent and environmental packaging products to the world.

Please inquiry us

Bagplastics@vip.163.com

| 1. Q: How many months of the silage wrap? |

| A: Standard includes TapeMMonths, 6 months and 12months are common in most counties. Rival silage wrap with a very high UV rating can up to 24months. Accept custom as your specification. |

| 2. Q: How about the packaging? |

| A: - Each roll with a carton, the carton accept custom printing. - 60-80 cartons put one pallet, and pallet wrap with 3 layer stretch film. |

| 3. Q: What is your silage film color? |

| A: Green, white and black are both popular colors. Accept custom your colors |

| 4. Q: Do you produce silage sheet? |

| A: Yes, the silage sheet is also our important products. Our 5 layers greenhouse film lines can produce a large size silage sheet. Welcome to your inquiry. |

| 5. Q: What is your material? |

| A: The material component includes LLDPE, UV, and other additives with 5 layers co-extrusion blown film technology from Europe. |

| 6. Q: Where your customers from? |

| A: At present, being used in Australia, New Zealand, America, and Europe widely for many years, extreme in most harsh and bad environment cities. |

| 7. Q: Can I visit your factory? |

| A: Very welcome, we trust our factory strength and service can enhance our cooperation process |

| 8. Q: What is the paper core? |

| A: Standard 3 inch paper core. Other bigger paper core includes 6 inches and 8 inches. |

| 9. Q: our silage film can wrap any grassy? |

| A: Yes, Rival silage film has excellent tensile strength, sufficient elongation, and large width coverage. 98% of clients feedback they are easy to use and the hay bales with great quality. |

| 10. Q: What is your standard specification |

| A: Standard sizes 500mm x 1500m x 2TapeMMic, 750mm x 1500m x 2TapeMMic. Your customized specification very welcome. |

we focuses on every production process quality control and recording so that there will be no defects in the delivery of each order. Sampling is conducted every 3 hours from production beginning, middle and end to make sure 100% meet customer requirements.

5 layers co-extrusion blown film is the most popular and latest packaging technology in the world. The significant advantage is this new technology makes the film more flexible, that means we can design the special formula for each layer according to the client’s specification to produce an excellent film. On the other hand for stretch wrap film, 5 layers technology has perfect mechanical properties, even better than 11 layer cast film. The application such as greenhouse film, heat shrink film, stretch wrap film, silage film, and other flexible packing.

| Item | White Green Color 25 micron good quality silage wrap film for hay bale wrap |

| Material | LLDPE / mLLDPE / UV |

| Temperature | From -30 up to 70℃ |

| Thickness | From 20mic to 50mic |

| Color | Green/White/Pink/Black or other colors (as your requirement) |

| Lifespan | Basic film for 6 months, customized up to 12 – 24 month. |

| MOQ | 40FT Container |

| Port | Tianjin port or other ports of China |

| Samples | Free sample accepted |

| Advantages | 1. Blown 5-layer film provide max mechanical strength 2. The guaranteed stretch of up to 300% without the problem 3. High UV-stability, effective protection from the sun even during full exposure 4. The film should not lose its clinging ability in hot weather 5. Excellent wrapping properties |

FREE SAMPLE CAN BE OBTAINED BY CONTACT with Please inquiry us

Bagplastics@vip.163.com

EMAIL: Please inquiry us

Bagplastics@vip.163.com

Application

The method of silage packaging originated in the 1970s, and the first use of forage film was by herdsmen in Australia and Britain, they used wrapped hay film (4-8 layers) in a specific packaging equipment to compact baled straw bale, and fermented it under anaerobic closed conditions. High quality nutritious feed is obtained by silage, especially in winter. This silage method is more flexible than traditional cellar storage, which has the features of lower labor cost and more nutritious feed after storage. Straw bales of different sizes and weights can be obtained by selecting appropriate packaging equipment according to different width of pasture film. Flexible and efficient silage ways can help reduce the cost of raising livestock and provide them with nutritious feed during cold, grassless winters. To ensure high quality meat and dairy products. Please inquiry us

Bagplastics@vip.163.com

As the world's most advanced silage technology packaging products, silage film has been widely used in Europe, the United States, Australia and other countries and regions and has more than 10 years of mature experience, we usually has three colors such as white, black and green for selection. White, black and green silage films had no significant difference in silage quality and storage time. White film reflected more heat than black one, which could reduced the thermal damage, while green film had less visual stimulation.

Please inquiry us

Bagplastics@vip.163.com

The silage film developed and produced by our company is mainly made of imported LLDPE and metalized PE, etc., and is processed by three-layer co-extrusion casting equipment with unique formula and technology.

Specification

25cm*25um*1500m/1800m

50cm*25um*1500m/1800m

75cm*25um*1500m

Please inquiry us

Bagplastics@vip.163.com

Colour: white, green, black(customized)

Package: 1 roll/carton

Please inquiry us

Bagplastics@vip.163.com

Features

1. Viscosity on film surface, good bonding between layers, oxygen resistance, water resistance, the formation of internal anaerobic environment, reduce deterioration.

2. The film has sufficient strength, including tensile strength, tear resistance and puncture resistance, which can ensure the herbage ensilage without damage and to maintain anaerobic environment.

3. Soft and resistant to low temperature.

4. Opaque, ensuring low light transmittance and avoiding heat accumulation.

5. Long working life, Packed bales can be stored in the field.

6. Stable in quality, resistant to sun light (uv) damage (exposed outdoors for more than one year)

7. High loading capacity (keep the package firm)

Please inquiry us

Bagplastics@vip.163.com

Advantages

1. Low investment, quick effect, high comprehensive benefits.

2. Excellent silage quality, high crude protein, low crude fiber, high digestibility, good palatability, fragrant smell, greatly improve the quality and yield of livestock meat and milk.

3. Little loss and waste, mildew loss and feeding loss were greatly reduced.

4. Long storage and fresh period.

5. Do not suffer seasonal, insolation, rainfall and ground water influence, can be piled up in the open air.

6. Convenient for storage and taking feed.

7. Convenient to transportation and commercialization, waste stretch film can be recycled, environmental friendly and no pollution, no liquid leakage into the ground.

Please inquiry us

Bagplastics@vip.163.com

Using Guide

1. 50-70%.During the use, it should not be overstretched. Recommended stretch ratio is 50-70%.

2. When wrapping, the latter layer should cover the former layer by 50%. After wrapping, the end part should be inserted into the straw layer. 6 layers is recommended .

3. If obvious damage on the surface, it is suggested to seal it with suitable adhesive tape immediately.

4. Silage bales can not be rolled on the ground. Keep away from toxic and dangerous chemicals.

5. Silage film bale should be kept away from plants and livestock, and frequently checked whether it is gnawed by rodents, such as mice, if damaged should be immediately sealed with appropriate tape. Please inquiry us

Bagplastics@vip.163.com

6. When used on the machine, check the upper and lower part surfaces damaged or not, small end surface damage can cause the interruption during the using process.

7. Unused silage film should be stored in a cool, dark environment and protected from moisture and surface mechanical damage.

Please inquiry us

Bagplastics@vip.163.com

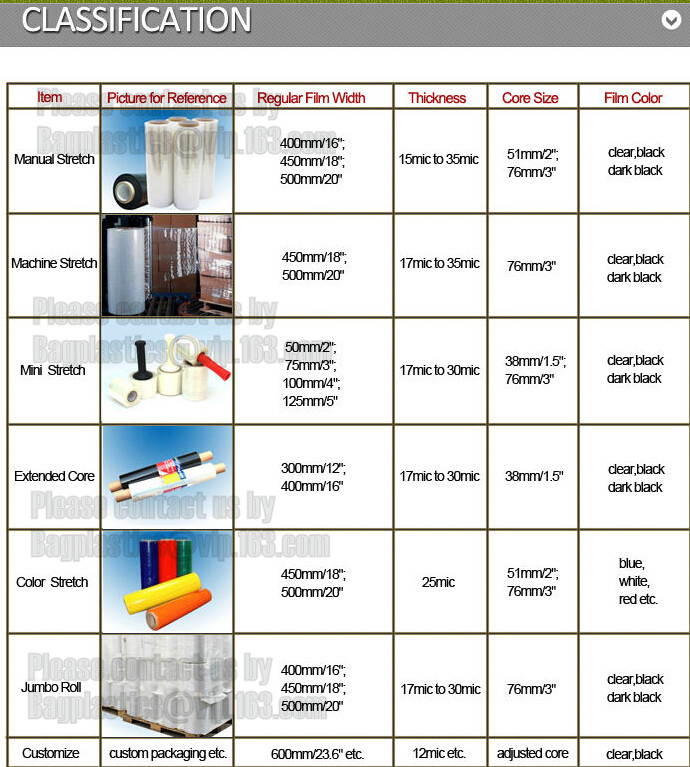

| Product name | Stretch film/wrapping film | |||||

| Product classification | hand use stretch film | machine stretch film | Jumbo roll stretch film | Mini roll stretch film | widened stretch film | colors stretch film |

| Color | clear,colors | clear,colors | clear,colors | clear,colors | clear,colors | red,black,white,blue, yellow,green,pink |

| Length/m | 100-1000m | 800-4000m | 800-4000m | 100-500m | 100-1000m | 200-1000m |

| Width/mm | 50-2000mm | 250-500mm | 50-2000mm | 50-450mm | 500-2000mm | 100-1000mm |

| Thickness range | 12-35um | 18-35um | 18-35um | 12-35um | 18-35um | 20-35um |

| Paper core | 50mm,76mm,offer customized | |||||

| Packing | 4roll/carton | 1roll/carton | 1roll/carton | requirement | / | 4roll/carton |

| Tensile rate | 200%-400% | 300%-600% | 200%-400% | 200%-400% | 300%-600% | 200%-400% |

Delivery Detail: 15days/20ft container, 25days/40ft container

If you are interested in our products, welcome to contact us, thank you!

Classification: Jumbo, Hand, Machine, Mini stretch film

Thickness: 17/18/20/23 micron or customized

Length: 300/500m, or customized

Width: 450/500mm, or customized

Weight: 1.5/2.5/3/5kg, or customized

Application: Industry, Agriculture, Household, etc.

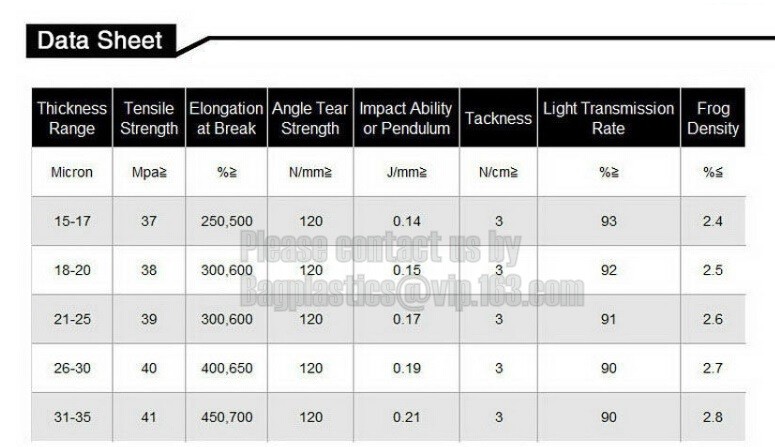

Data Sheet of LLDPE Plastic Wrapping Stretch Film:

| Packaging Details: | 1 ROLL/CTN ; 4/6 ROLLS PER CARTON |

|---|---|

| Delivery Detail: | 7-10 days after deposit |

Food Grade

Reliable,Best Service

Factory Direct Price