Allwin Machine & Equipment Co.,Ltd |

|

Verified Suppliers

|

|

HZ50 Bead Mill 37kW Water Base Paint Ink High Viscosity Slurry Products

HZ series is disk type structure with Dynamic discharge, could meet all kinds of micron fineness griding,, widely used in paints coating, chemical fiber,food,cosmetic and namo materials industry. this series are general structure with flow discharge, super wearable materials for micron fineness demands.

Allwin brand grinding mills are easy to install, and operation is rather humanized considering the safety, working comfort level,etc. All mills are tested before shipping, which makes sure of availability after mills reach to your side. The installstion can be operated with attached installation and maintainence instructions. If there are other problems need our assistance, contact us, we offer on-line assistance as soon as possible.

The Main parameter

| No | main parameters | HZ 50 | Note |

| 1 | Explosion-proof motor kW | 37kW | ( Ex-proof) |

| 2 | Effective volume of Grinding chamber (L) | 50L | |

| 3 | Water pressure (MPa) | 0.3 | |

| 4 | Cooling water consumption (L/min) | 2.0-2.5 | Advise offer the Cooling water less 10°C |

| 5 | Dimension*W*H (mm) | 1900*1200*2000 | |

| 6 | Weight (kg) | 1500 |

The Main instructions:

| NO | Items | HZ 50 | Notes | |

| 1. | Core technologies | Mechanical sealing | Intelligent double mechanical seal with mandatory with self-lubricating-cooling system | Allwin technology |

| Inner Chamber | Silicon Ceramic | Super wearable | ||

| Grinding system | SUS304 stainless steel | Disc type | ||

| Static discharge screen ring | Axis discharge and SUS304 Screen (Dynamic rotation) | |||

| 2. | Feeding and discharging end covers on the Chamber | 304 stainless steel | Easy Clean | |

| 3. | Bearing | NSK Bearing | ||

| 4. | Feed pump | 1” Pneumatic diaphragm pump with Buffer tank | ||

| 5. | Outer chamber | 304 stainless steel | ||

| 6. | Dispersing shaft | 40Cr with hard chromium plating | ||

| 7. | Electrical appliances | Motor | 37kW Ex-proof | Brand:Pinxing or Wannan |

| Safety protection system | Material temperature, chamber pressure, sealing liquid level, sealing liquid pressure | |||

| Electrical components | Electrical box, pressure gauge, thermometer, solenoid valve, winding pipe with EX-proof | |||

| Light alarm system | with | |||

| Electrical brand | Delixi | |||

| 8. | Cooling water pipeline | Hose+ Hard tube | ||

| 9. | Trace slide | 1 sets for free | ||

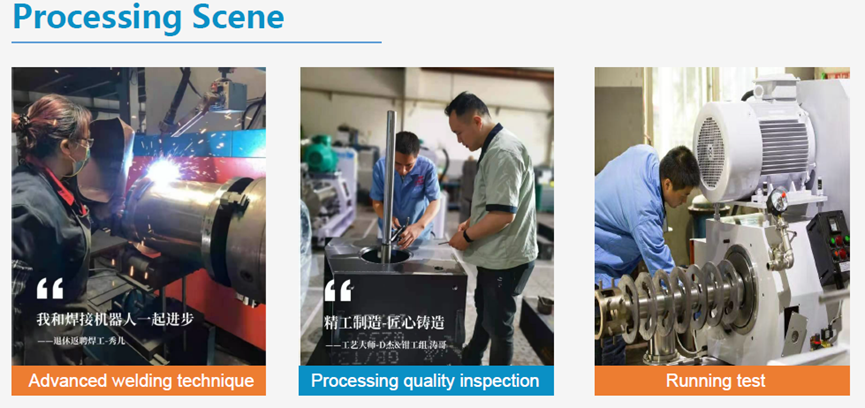

Pictures of Customers visit our plant

Related products:

Allwin also offer related grinding mediums and dispersing machines for grinding and dispersing processing.More informations can contact our sales manager.

The After sales service:

1. Video instructions for installation and commissioning, if need, we will arrange engineer to your factory.

2. 12-24 hours feedback any customers questions, firstly offer the video help you solving, if need arrange maintenance engineer for you.

FAQ:

Q1:Trading company or manufacturer?

A1: We are the manufacturer.

Q2: Is it available if we want to visit your plant?

A2: Yes, of course. Warmly welcome you to visit our factory to know our process, our technology.and communication face-to-face is rather benecial to built trust degree.

Q3: Do you have own R&D team?

A3: Yes, we have 12 engineers, and our products could be customized for your requirements.

Q4: How about the quality?

A4: We have professional engineers and a strict QA& QC system, Our factory comply with the IS09001 standard strictly. Warranty of all new disperser is one year free.

If need more detailed information and price ,please contact us soon and warmly welcome to visit us!