KingPo Technology Development Limited |

|

Verified Suppliers

|

|

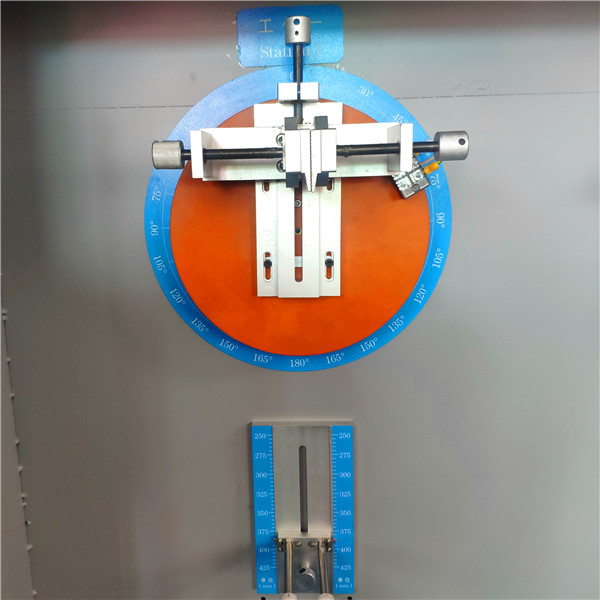

4 Station Flexing Test Apparatus

Instrument Introduction

1.1 Main uses

This instrument is mainly used to test the flexural fatigue strength of AC power cords and plug leads. It is suitable for rocking motion testing of plug power cords under a certain load.

The instrument has no-load (only measures life, does not make open circuit judgment) On-off (makes open circuit judgment), external load (also equipped with load machine, L, N line with large current and voltage load, can make open circuit judgment), internal load test function.It has the advantages of reliable detection, stable operation, and the ability to test four products of the same type at the same time. It is an ideal instrument for the laboratory and quality control department to test related performances such as plug wires and connectors.

1.2 Design standards

This instrument complies with IEC60335 ,UL817, IEC60884, VDE0602, GB2099 and other standards.

| No. | Items | Specifications |

1 | Input power | 220VAC±10%, 50/60Hz |

2 | fuse | 10A/250VAC |

3 | Output Power | 2000W |

4 | Number of sample cores | 3-core |

5 | Test station | 4 station |

6 | Fixture | Can be selected according to need |

7 | Inside | 0-25A |

8 | External load | 0-300V 0-20A |

9 | Bending angle | ±(5°~ 180°) |

10 | Bending accuracy | ±0.5° |

11 | Bending speed | ±(5°~90°), 5~60 times/min arbitrary setting; ±(91°~180°), 5~40 times/min arbitrary setting |

12 | Testing frequency | Arbitrary setting from 1 to 999999 times (error: ±0.1 time) |

13 | Failure alarm | The buzzer alarms when the test sample line is broken, and the touch screen has a corresponding prompt |

14 | Qualification tips | The sample to be tested bends to the set number of tests, the touch screen has corresponding prompts and warnings |

15 | Dimensions | 1450 X 800 X 1400 (width X depth X height) |

16 | weight | About 300 Kg |

Installation Instructions

2.1 Disassembly and inspection

1. Check whether the instrument has been injured or damaged during transportation;

2. Check whether the instrument is upside down;

3. Check whether the specifications on the nameplate of the instrument are consistent with the order;

4. Check whether the packing list is consistent with the actual product.

If the above phenomenon occurs, please do not use the instrument and contact us in time.

2.2 Safety regulations

1. Before using the instrument, please read the manual carefully and understand the relevant safety signs and operating procedures to ensure safety.

2. Check whether the power supply voltage is consistent with the specifications provided on the nameplate. The power supply must be well grounded.

3. Non-professionals should not open the door or cover of the instrument to prevent electric shock.

4. The instrument panel display cannot be scratched with sharp objects.

5. The user must not change the circuit or parts of the instrument by himself, otherwise the quality guarantee will be invalid and suppllier will not be responsible for the consequences.

2.3 Installation requirements

1. The instrument should be placed on a level and stable work surface. If there is any unevenness, it should be adjusted first.

2. The ambient temperature used by this instrument is 25±10°C, and the relative humidity is 50±30%RH.

3. The instrument should be kept away from heat and corrosion sources.

4. The instrument is connected to a 220V/50Hz±10% power supply with good grounding.