Shenzhen Best Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Automatic lithium battery pack assembling line 5000pcs per hour

Equipment name: Automatic production line of power energy storage battery pack

Specification model: BT-2113-18650

I. Scope of application and function introduction

1. Scope of application:

Mainly used in automotive battery modules. Fully automated production of power battery, energy storage battery, power tool battery pack and other application batteries

2. Only 3 operators are required to operate the battery pack from the box to the completion of welding. Due to the difference in technology, some positions cannot be operated by machines, so the number of operators varies

3, optional cell scan code function, the state of the cell data into the bracket or combined battery, the battery data can be traced, can also be used as cell OCV comparison, select defective products

4, 4 axis Yamaha robot automatic support, stable and reliable performance

5, using Hikvision series CCD battery polarity identification, to ensure that the battery into the bracket without polarity error phenomenon.

6, the use of cell spacing combination mechanism, suitable for different spacing of the battery, to solve the problem of opening multiple fixture due to different spacing

7. Use 2 sets of laser to clean the stains on the anode and cathode surfaces of the cell to ensure the welding quality

8. Device support functions:

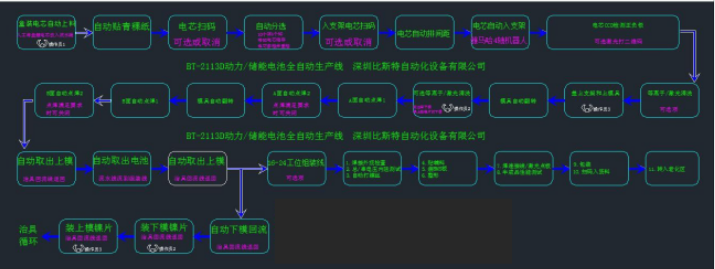

18650 Automatic boxed cell (10*10) automatic feeding → automatic veneer → automatic code scanning →

Automatic sorting (10 grades OK, First gear NG) → automatic cell sorting → automatic scanning → robot into the bracket →CCD vision positive and negative pole detection → laser cleaning Side A → mold turnover 1→ Spot welding on Side A 1→ Spot welding on side A 2→ mold turnover 2→ Spot welding on side B 2→ spot welding on side B 2→ Automatically take out the cover → automatically take out the battery → battery semi-finished assembly line (spot welding appearance detection → paste accessories → protection plate connection → shaping → comprehensive performance test, etc.)

9. Maximum stroke of the equipment: 430MM in the X-axis direction, 270MM in the X-axis direction, 21 cores in the X-axis direction and 13 cores in the X-axis direction at 20.5mm spacing

10. Production efficiency: 5000-6000pcs /H

Introduction to equipment combination

Unit 1

◎ Electric core part) : 18650 automatic box electric core (10*10) automatic feeding, one-time 6

Box (600PCS18650 cell)

◎ Automatic finishing pad

◎ Automatic code scanning → automatic sorting part (10 OK files,

one NG file, 2 /3 /4 /5 can be set as the same file, increase the

number of cell storage, each slot is 100PCS, two slots are in the

same file, then 200PCS, 3 slots are in the same file, then 300PCS)

Unit 2

◎ Automatic code scanning → automatic spacing → robot into the bracket →CCD battery positive and negative electrode detection → Laser cleaning on Side A (optional) → mold turnover 1→ Laser cleaning on Side B (optional) → Spot welding on Side A 1→ Spot welding on Side A 2→ Mold turnover 2→ Spot welding on Side B 2→ Spot welding on Side B 2→ Automatically take out the cover → automatically take out the battery → battery semi-finished product cycle assembly line (spot welding appearance detection → paste accessories

→ Protection plate connection → shaping → comprehensive performance test, etc.)

Unit 3

◎ One cycle line for double speed chain mold

◎ 15 sets of spot welding mold carrier (L530*380MM)

◎ 15 sets of upper and lower cover plates of spot welding mold for each battery model

Semi-finished battery output line *1

◎ One reflux line for upper mold carrier

Unit 4

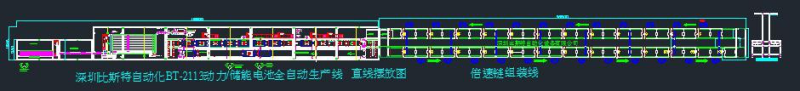

Double speed chain assembly cycle line *1 (L16.5*W1.3*H2 meters)

Bt-2410a, 24 series total/series voltage internal resistance tester *1 set (optional)

◎ Double position laser spot welding *1 set (protection plate and B+B- inspection line)

◎ BT-85V05C50F Battery pack performance comprehensive tester

Unit 5

◎ MES electronic Kanban system (one for main server, one for main display screen, one for SOP sub-kanban, one for each station)

◎ Electrostatic eliminator *2

◎ Assemble the static ring of the cycle line and static alarm, 1 set for each station

Production flow chart

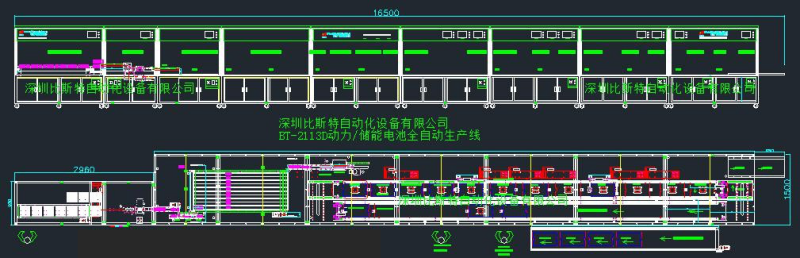

Equipment layout Diagram

Note: BT-2113 power/energy storage battery pack automatic production line L16.5*W1.5* 1.76m

Double speed chain cycle assembly line L16.5*W1.3*2M

Note: BT-2113 power/energy storage battery pack automatic production line L16.5*W1.5* 1.76m

Turning line L4.6 * W1.8 H0.8 M

Double speed chain cycle assembly line L16.5*W1.3*2M

Five, equipment environment requirements

1, power supply: AC380V±10%, 30KW 50HZ±10%

2, gas source: 0.4-0.8mpa, no water mist, no impurities

3, ambient temperature: 10-45℃

4, environmental humidity: no more than 85r.h (no moisture condensation)

5, the environment without strong vibration, no corrosive gas and flammable and explosive gas

Advantages and disadvantages of the equipment

1, BT-2113 power/energy storage automatic production line, the new energy battery industry to achieve the dream of high-end automatic production factory

2, BT-2113 power/energy storage automatic production line, battery size compatible, subject to 18650, X axis direction 21 core (430MM), Y axis direction 13 core (270MM)

3, BT-2113 power/energy storage automatic production line, can be segmented independent use, can also be used in combination

4, automatic line standard: standard type standard with BT-8000A spot welding power supply, optional Miaji series standard with Yamaha robot, standard with Gene scan code accessories, standard with radium Marking machine, radium laser cleaning machine.

5, BT-2113 power/energy storage automatic production line, compact design, reasonable structure, the overall size is (from automatic on the core to automatic spot welding) : L16500MM*W1500MM*H1760MM, the battery pack assembly cycle line is designed as L16500MM*W1300MM*H2000MM, which is compatible with large and small factories, and seamless docking can be achieved between each section without changing the structure.

6. Battery semi-finished product assembly line (spot welding appearance detection → paste accessories → protection plate connection → shaping → comprehensive performance test, etc.) : according to different product requirements and requirements of accessory drawings.

7, the company's production of automatic line, efficiency up to: 5000-6000pcs /H (depending on the balance of cell position), stable quality, low failure rate.

8, high degree of intelligent equipment, simple debugging, easy to learn and understand.

After-sales service

1. Party A is obliged to train party B's equipment users in installation, debugging, use and maintenance for free, so as to ensure that the demander's operators can operate normally and independently, and the maintenance personnel can handle common problems independently

2. The warranty period of the equipment is two years. Party A shall be responsible for three guarantees in accordance with national laws and regulations. After the warranty expires, lifelong maintenance, and at cost price to provide spare parts and wearing parts. If the problem is handled off-site, the supplier shall give a clear reply by email or written form within 4 hours