Guangdong XWELL New Energy Technology CO., LTD. |

|

Verified Suppliers

|

|

Single Side Fully Automatic Electric Lithium Battery Spot Welding Machine For Cylindrical Battery Pack Welding

Product Description

MD-ASW with welding head rotation function, is suitable for battery

pack spot welding and assembly in the factory for 14500 / 18650 /

21700 / 26650 / 32700 multi-parallel multi-series combination.

The Automatic Battery Pack Spot Welder is a general platform of

automatic processing technology based on CNC, suitable battery pack

spot welding and assembly in the factory. Compared with manual spot

welding machine, the efficiency and accuracy of welding have been

greatly improved.

Product Features

1. Support break point start, support automatic start and manual

start mode conversion.

2. It has a false spot welding and out of spot welding alarm

function.

3. Programming is simple, and it supports any point programming and

array programming. 99 groups can be saved programming files.

4. Welding needle replacement forecast reminder.

5. Own welding current monitoring system, real-time monitoring of

welding current.

Product Advantages

1. High stablity

2. Strong generalty

3. Production control

4. Long maintenance

5. Efficient and precise

6. Welding pulse width is adjustable, welding machine is firm and

spatter is small, welding spot is not colored.

7. 7 Inch Touch screen, more convenient operation, more clear

display

8. Three file programming modes, manual input, array and CAD DXF

schema import, simple and fast response to various complex program

editing

9. The welding head has the function of air cooling or water

cooling, which can effectively reduce the influence of the

temperature of spot welding needle on the welding quality.

10. It can store 99 groups of files, which are easy to call and do

not need complicated wiring and shunting process.

11. One-button calibration function for whole deviation of solder

joint, which can be used to calibrate point deviation caused by

needle replacement or other reasons.

12. Spot welding efficiency is higher, welding speed per spot is

less than 0.35S (according to different speed of the selected

welding machine), single side spot welding machine can reach 2800

cores per hour.

13. The core parts are imported from Japan and Taiwan. The

accuracy, stability and service life of the machine are more than

twice that of other parts made in China.

14. Welding automatic alarm and stop function, after clearing the

fault can continue spot welding

15. Machine with power cut or breakpoint continue function, can

manually adjust any position for spot welding

16. Welding machine can be optional, according to different

requirements of customers, different welding machines can be

selected to effectively meet customer needs.

Product Specification

| Model No. | MD-ASW |

| Y-axis travel | 500mm (customizable) |

| X-axis travel | 350mm (customizable) |

| Max spot welding speed | 0.35s/point (1 hour:about 2800 units18650 cells) |

| Motor drive speed | 1000mm/S |

| Max load electric cores | X direction: 26; Y direction: 26 |

| Capable file group storage | 99 groups |

| Operating system | embedded system human-machine interface |

| Transmission mode | Taiwan precision screw with guide rail |

| Driving mode | stepper servo motor |

| Repeat positioning accuracy | ±0.02mm |

| Dimensions | L: 900mm, W: 900mm, H: 1750mm |

| Power | 4000W |

| Machine weight | 200KG |

| Max bearing weight of Y-axis | 35KG |

| Input power supply | single-phase AC 220V/50Hz |

| Air Source | 0.4-0.6 Mpa |

Product Application

With the corresponding fixture, the spot welding machine can weld

18650, 26650, 32650 and other cylindrical batteries, can also be

customized for a variety of cylindrical battery, square battery,

button battery and etc.

Product Operation

1. Setting the parameters of welding on the touch screen. (The same

product only need to be set once)

2. Put the fixture with the battery pack on the quick clamping

position.

3. Press the start button, MD-ASW automatically complete all

welding actions.

4. MD-ASW sound to prompt operator replacement of new fixture

(battery pack).

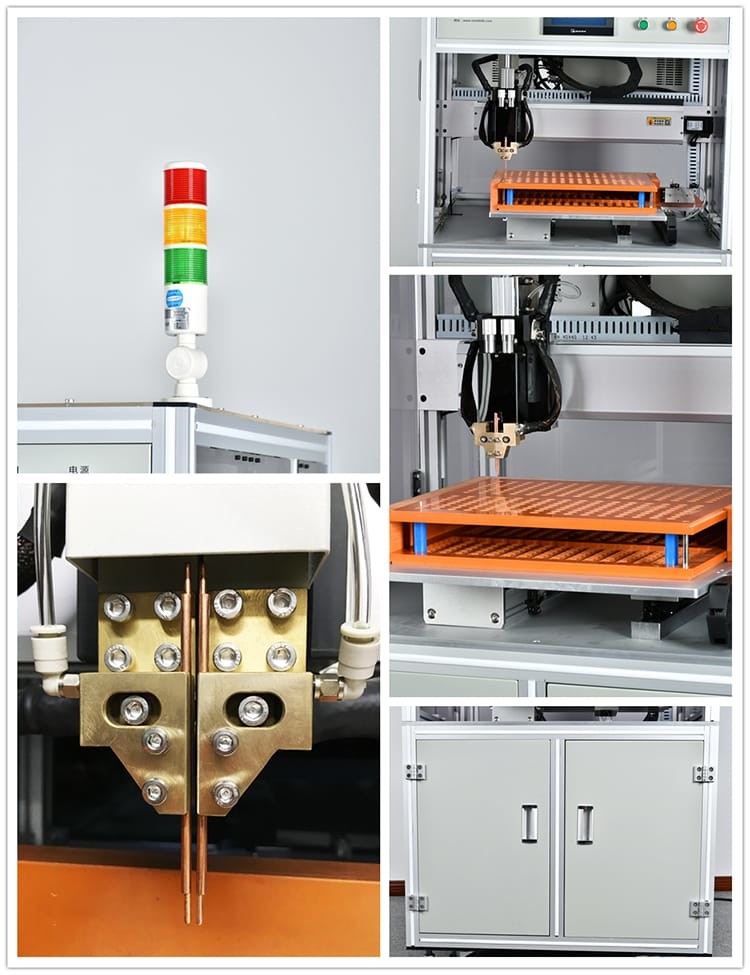

Single side battery welding machine structure

Single side spot welding machine details

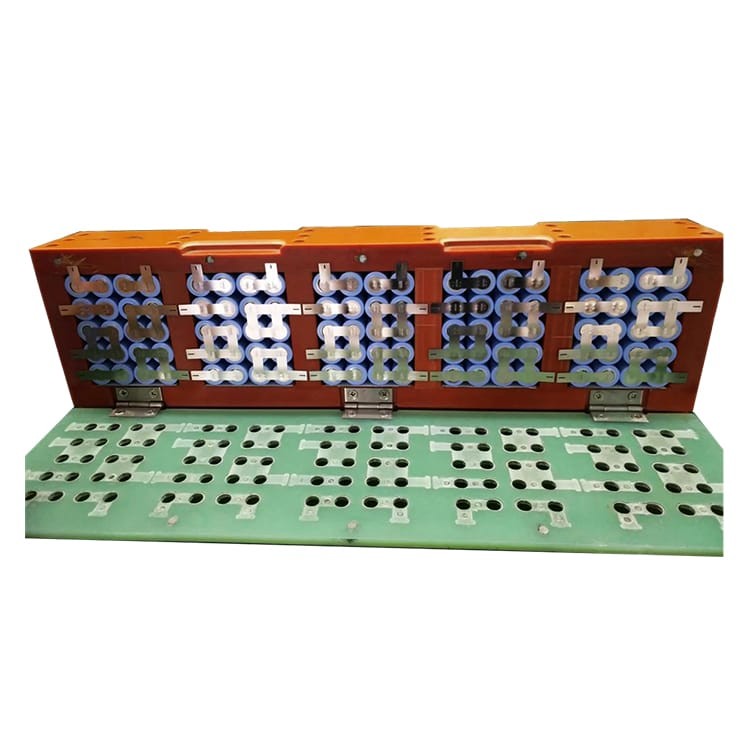

Battery pack welding samples

Our factory