Guangdong XWELL New Energy Technology CO., LTD. |

|

Verified Suppliers

|

|

Semi Automatic 8000A Double Sides Spot Welding Cylindrical Lithium Battery Spot Welding Machine

Product Description

The Automatic Battery Pack Spot Welder is a general platform of

automatic processing technology based on CNC, suitable battery pack

spot welding and assembly in the factory. Compared with manual spot

welding machine, the efficiency and accuracy of welding have been

greatly improved. Humanized design makes the operation and

debugging very easy and convenient. Design of components built-in

makes appearance more concise. We can also offer CNC welding

machine. Welcome your inquiry to us for more details.

Product Features

1. Support break point start, support automatic start and manual

start mode conversion.

2. It has a false spot welding and out of spot welding alarm

function.

3. Programming is simple, and it supports any point programming and

array programming. 99 groups can be saved programming files.

4. Welding needle replacement forecast reminder.

5. Own welding current monitoring system, real-time monitoring of

welding current.

6. Suitable for electric car battery, car battery module, balance

the car battery, scooter battery, mobile power supply, start the

battery module, power tools batteries, laptop batteries, etc.

Various battery combinations!

7. The welding efficiency is about 8 times higher than that of

manual workers, with high stability, labor saving and time saving.

Product Advantages

1) Induce load voltage, control voltage by feedback, and realize

high quality welding.

2) Preheat, Main Heat's power mode, preheating before welding, to

ensure stable welding quality.

3) Keep the continuity of energy density, shorten the welding time,

and reduce the deformation and color of base metal. (Welding time

controlled in microseconds, continuous output mode)

4) Easy to change from low current to high current, suitable for

precision welding.

5) The upper and lower limits of current can be set to simply judge

whether the welding quality is good or not, which is suitable for

welding automation platform.

6) The welding current rises with the time of electrification to

ensure the welding effect.

Product Specification

X-axis stroke | 500mm (customizable) | Operating system | Embedded system + HMI |

Y-axis travel | 350mm (customizable) | Transmission mode | Screw rod+precision linear guide rail |

Max spot welding rate | 0.5S/point; 1500-1800pcs/h | Driving mode | Hybrid servo motor |

Max speed of motor drive | 1500mm/S | Nickel welding thickness | 0.1mm-0.3mm |

Max loaded cell (18650) | About 500pcs (20 * 25) | Dimension | 900L*1100W*1930H |

No. of file groups saved | 99 groups | Positioning accuracy | ±0.02mm |

Weight | 300KG | Horizontal bearing weight | 35kg (OEM) |

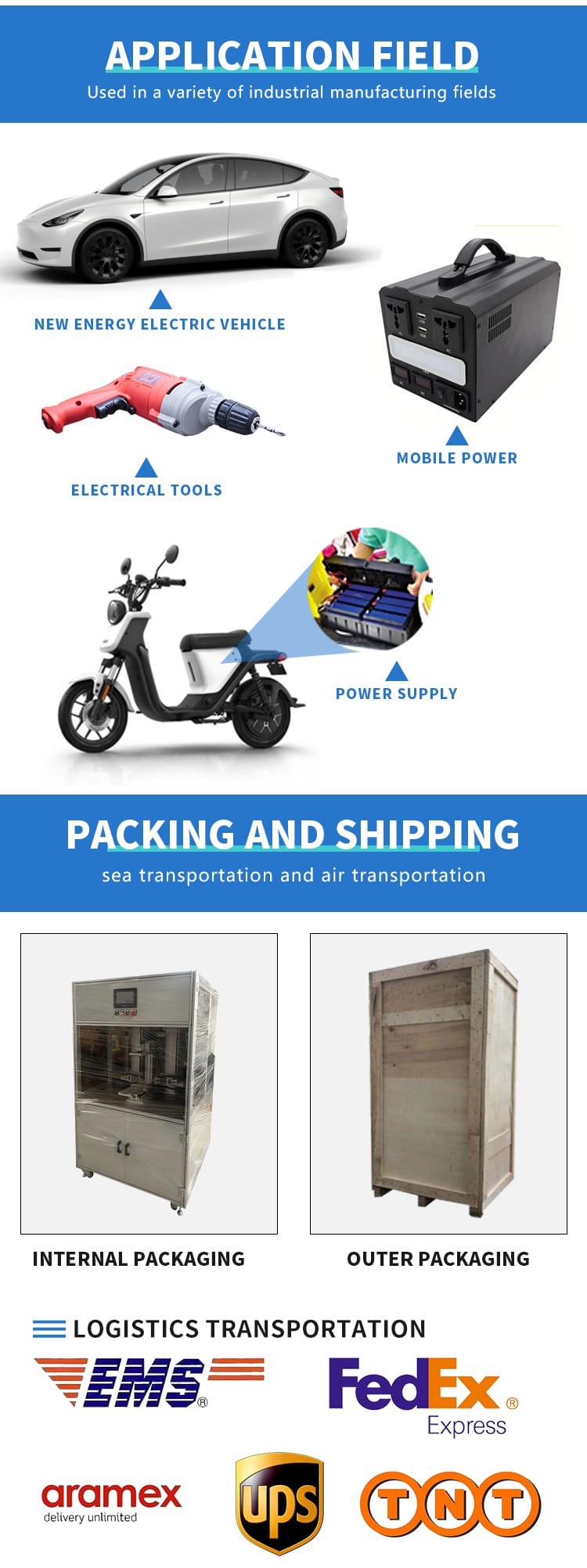

Product Application

Power Battery 18650 / 26650 series-parallel combination of

batteries, multi-parallel multi-series combination, electric tool

battery, torsion car battery (1 die spot welding 6 groups) , energy

storage battery pack, 18650 Battery Group, 26650 Battery Group,

32650 Battery Group, Electric Bicycle Battery, solar Street light,

Ternary Lithium Ion battery, digital lithium ion battery, lithium

iron phosphate battery, etc. .

Product Operation

1. Setting the parameters of welding on the touch screen. (The same

product only need to be set once)

2. Put the fixture with the battery pack on the quick clamping

position.

3. Press the start button, MD-ADW automatically complete all

welding actions.

4. MD-ADW sound to prompt operator replacement of new fixture

(battery pack).

Spot welding machine details