TANGSHAN MINE MACHINERY FACTORY |

|

Verified Suppliers

|

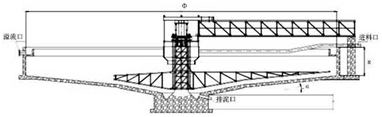

Tailing Mining Ac Motor Thickeners In Mineral Processing For Metal Industry

1. Product introduction:

Out overflow weir instead of inner overflow weir increases the

sedimentation area and not easy to block;

Oblique feeding instead of horizontal feeding solves the blockage

problem;

A tranquil flow device reduces material flow rate, so that the

overflow becomes more uniform with lower turbidity.

| Name | Mineral Tailing Mining Thickener For Metal Industry |

| Model | High-Rate Thickener |

| Material | Zinc Lead |

2. The main features are:

The degassing box is equipped to avoid the solid particles attaching to the bubbles remained in the feeding pulp which settle as the parachutes.

The outlet end of the feeding pipe is installed below the solution level to avoid air mixing the pulp during the feeding.

3. Appearance and main parameters:

3. Appearance and main parameters:

| Model | Bridge structure | Angle | Diameter φ | Depth H | Inlet port | Overflow | Mud outlet | Motor Power |

| α m m kw | ||||||||

| NXZ-09 | Full bridge | 8° /9.5. | 9 | 2.5 | DN100 | DN100 | DN80 | 4 |

| NXZ-12 | 12 | DN150 | DN150 | DN100 | ||||

| NXZ-15 | 15 | 3 | DN200 | DN200 | DN150 | |||

| NXZ-18 | 18 | 3.5 | 5.5 | |||||

| NXZ-20 | 20 | DN250 | DN250 | DN200 | ||||

| NXZ-24 | 24 | |||||||

| NXZ-30 | 30 | DN300 | DN300 | DN200 | 7.5 | |||

| NXZ-35 | 35 | |||||||

| NXZ-38 | Half bridge | 6°+12°/9.5° | 38 | 3.5 | DN400 | DN400 | DN250 | 11 |

| NXZ-40 | 40 | |||||||

| NXZ-45 | 45 | DN500 | DN500 | DN300 | 15 | |||

| NXZ-55 | 53 | |||||||

| NXZ-60 | 60 | DN600 | DN600 | DN350 | 22 | |||

Company introduction

Tangshan Mine Machinery Factory is a specialized manufacturer that produces complete sets of equipment for metallurgy, mining, building materials, environmental protection, as well as the design and manufacture of complete sets of sand and gravel materials, and the design and manufacture of dry tailings discharge. The company was founded in 1971 and turned into a joint-stock enterprise in 1997.

Various processing and testing equipment: 8 meters, 5 meters, 4 meters vertical lathes, 8 meters, 5 meters, 3.15 meters gear hobbing machine, 6 meters planer, precision boring machine, medium frequency quenching and other larger processing equipment and automatic welding, ultrasonic welding More than 300 sets of flaw detectors, W15-23 material testing machines, aging vibration devices, etc.

FAQ

Q1: Hi, are you a mining machinery manufacturer?

Answer: Yes, we are a professional manufacturer of mining machine.

Our company welcomes customers to visit our factory at any time.

Q2: How long is the warranty period of your equipment? Does your

company provide spare parts?

Answer: The warranty period of our machine is one year. For those

wearing parts, we guarantee to provide high-quality parts for a

long time.

Q3: How long does it take to deliver?

Answer: Production usually starts after receiving the advance

payment. Small machine is guaranteed to be delivered within one

month. Large-scale machine is guaranteed to be delivered within 2-3

months.

Q4: Do you provide machine operation guidance?

Answer: Yes. We have professional engineers for installation,

commissioning and operation guidance.