Wuxi Jianlong Packaging Co., Ltd. |

|

Verified Suppliers

|

|

Bag Robotic Palletizer, Robot Palletizer, Automatic Flour Bagging Palletizing System

Introduction:

Robot palletizer is use for packing bags, cartons even other kinds products on one by one pallet. No problem make program to realize different pallet type according to your requirements.The palletizer will pack 1-4 angle pallet if you set. One palltizer is ok working along with one conveyor line, 2 conveyor line and 3conveyor lines.Its optional.Mainly use in automotive, logistics, home appliances, pharmaceuticals, chemicals, food and beverages industries,etc.

The palletizing robot is mainly designed for palletizing applications. The articulated arm has a compact structure and can be integrated into a compact back-end packaging process. At the same time, the robot realizes the item handling through the swing of the arm, so that the previous incoming material and the following palletizing are connected, which greatly shortens the packaging time and improves the production efficiency.

The palletizing robot has extremely high precision, precise picking and placing of items, and fast response. The robot's palletizing action and drive are realized through a dedicated servo and control system. It can be repeatedly programmed through the teach pendant or offline programming to achieve different codes for different batches of products Fast switching of stacking modes, and can realize the palletizing operation of a single machine on multiple production lines!

| Weighing range | 10-50kg |

| Packing speed (bag/hour) | 100-1200bag/hour |

| Air source | 0.5-0.7Mpa |

| Working temperature | 4℃-50℃ |

| Power | AC380V,50HZ, or customized according to the power supply |

Characteristic:

1. Simple structure, few parts, low failure rate and convenient maintenance.

2. It occupies less space, which is good to the layout of the production line and leaves a larger warehouse area.

3. Strong applicability. When the size, volume and shape of the product change, only need to be modify the parameters on the touch screen. Different grippers can be used to grab bags, barrels and boxes.

4. Low energy consumption and reduced operation cost

5. The operation is simple, only the starting point and the placement point need to be located, and the teaching method is simple and easy to understand.

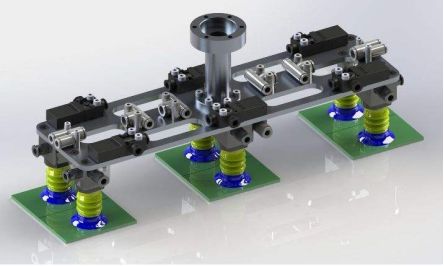

Robotic gripper

Customize different robotic grippers according to different needs of various industries.

Grab gripper

Splint gripper

Vacuum gripper, robot suction gripper

Cooperation partner: