ZhongHeng Machine Manufacture Co.,Ltd |

|

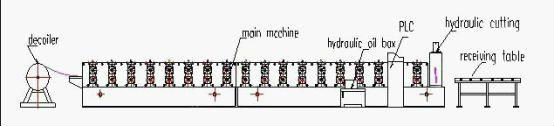

Metal suqare gutter roll forming machine with 11.5kw motor

Description

High standard aluminum downspout water gutter rolling forming

machine includes in unpowered decoiler unit, sheet guiding

equipment, roll forming system, cutting equipment, hydraulic

station, electric controlling system and product supporter.Curving pipe forming machine is the complementary equipment for

down pipe forming machine. It can make curve for down pipe to meet

the requirement of practical engineering projects.

Specification

NO. | ITEM | PARAMETER | NOTE | |

1. | Suitable | Type | Pre-painted sheet, |

|

Width(mm) | 300mm |

| ||

Thickness(mm) | 0.3-0.8mm |

| ||

Yield stress(mm) | G220-G300 |

| ||

2. | Product | Detail as the attached file | ||

Length | Any length |

| ||

3. | Power | Type | 380v/3ph/50hz | Motor brand shanghai Lichao |

Main Motor power | 11.5kw | |||

Cutter power | 7.5kw | |||

4. | Forming speed(m/min) | 8-10m/min | Not include the time of cutting | |

5. | Manual Decoiler | Type | Manual |

|

Max capacity | 5t |

| ||

Suitable coil OD(MM) | 1000 |

| ||

Suitable coil | 508 |

| ||

6. | Forming stand | 14 | Depend on actual design | |

7. | Thickness of structure | 16mm |

| |

8. | Forming shaft diameter(mm) | 70solid |

| |

9. | Type of cutting | Roll formed and |

| |

10. | Control system | Panasonic PLC and inverter |

| |

11. | Install dimension(depend on the final design) | 5.2m×1.1m×1.3m | Without panel length | |

12. | Total weight (Approx) | 3T | Depend on final design | |

Flow chart

Uncoiling→Feeding material into machine→Roll forming→Measuring length→

Auto cutting→Products receiving

Competitive Advantage:

1. Low cost

2. Welded iron type

3. Single cylinda

4. excellent quality

5. Operate easily

Packaging Details

a.need one 20ft container;

b.Fit for ocean shipping;

c.Main body of Automatic Chrome Plated Steel Roof Profile Cold Roll

Forming Machine fixed to container by 8mm diameter steel wire;

Rollers and shaft is covered with anti-rust oil; Spare parts in

carton box.

Delivery Time

within 30 days after our bank receives your deposit

FAQ

Q. Why your price is higher than others?

A.---- As we persist on that each factory should put quality at the

first place. We spend time and

money on developing how to make machines much more automatic, accurate and high

quality.

We can make sure that our machine could use more than 20 years

without any problem. We can

provide 2 years free quality assurance.

Q:what is the delivery time

A:---- Normally speaking, welded pipe making machine could be made

without 45 working days. Ifyou need machines in a hurry, we can

make it for you less than a month.

Q. How to visit your company?

---

A.Fly to Beijing airport: By high speed train From Beijing Nan to

Cangzhou Xi (1 hour), then

we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao

to Cangzhou Xi(4.5 hours), then we can pick up you.