ZhongHeng Machine Manufacture Co.,Ltd |

|

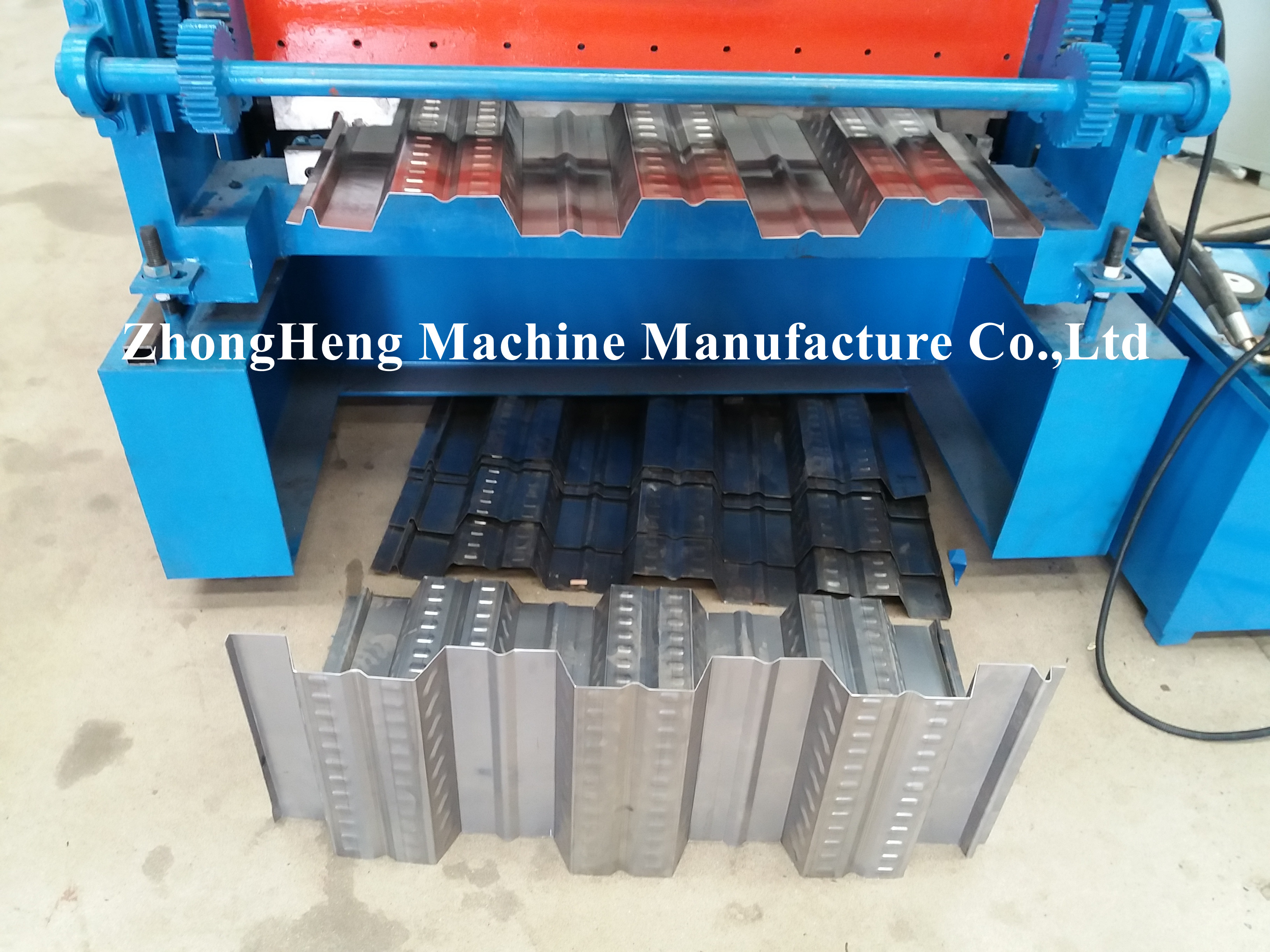

Galvanized Steel Floor Decking Steps Cold Roll Forming Machine /

Equipment

Specifications

Machine components:

No. | Name | Qty |

1. | De-coiler | 1 Set |

2. | Roll Forming Machine | 1 Set |

3. | Hydraulic Cutting Device | 1 Set |

4. | PLC Control Box | 1 Set |

5. | Output table | 1 Set |

Technical description:

Uncoiler | ||

1 | Load Capacity | 5T |

2 | Coil Inner-Diameter | ≤508mm |

3 | Coil Outer-Diameter | ≤3000mm |

Pre-Shearing | ||

1 | Function | It is used for cut the coil when the machine processed a batch of products as required, it can save material well. |

Roll Forming M/C | ||

1 | Material thickness | 0.8 - 1.2mm |

2 | Forming Steps | 30 - steps |

3 | Line Speed | 8 to 15m/min |

4 | Drive | Independent motor and moved by chain |

5 | Material of shaft | high grade No.45 steel after treatment |

6 | Material of Roller | 45# steel polished and coated with chrome HRC55-60° |

7 | Shaft Diameter | 100 to110mm |

8 | Main Motor Power | About 15KW |

9 | Voltage | 380V/50HZ/Three Phase |

Hydraulic Cutting Device | ||

1 | Cutting Die | Cr12, HRC58-62 |

2 | Tolerance | ±2mm |

3 | Hydraulic power | 11kw |

PLC Control System | ||

1 | Type | PLC Frequency Control System with touch screen |

2 | PLC brade | Japan Panasonic |

3 | Encoder Brand | Omron |

Competitive Advantage:

1. operations safety

2. nice appearance, high quality

3. reasonable price

4. CE certification

5. High stength

Description:

A.

We will arrange engineers to supervise installation and make adjustment for the equipment; Buyer should pay

$50 for each engineer every day. The buyer should be responsible for transportation

(including round-trip ticket), insurance, accommodation.

B. Guarantee period:

1.

The warranty will be maintenance, maintain in the guarantee period of one year starting from delivery.

Because of the quality of equipment during guarantee period, we will provide the parts free of charges,

which is in the conditions of correct operation. (Natural disasters or factors which can’t forced by human

are excluded).

2.

If the equipment are out of work in the guarantee period, the buyer needs our repairman to come to buyer’s

factory, the buyer should be responsible for the tickets(including round-trip ticket), the fee of transportation to

the buyer’s factory and the fee of accommodation. Required to change spare parts, the buyer should afford

freight fee and we don’t ask extra fee.

C. Detail Engineering

1. Lay out and general arrangement drawing

2. Funation lay out drawing

3. eration and maintenance instructions

D. Training

During installation and adjustment of the equipment, our engineers shall provide the training to buyer’s

personnel to operate and maintain the equipment. Additional trading can be provided on request.

1.

Foundation construction, electrical works, and civil engineering;

2.

Electrical wire, mechanical tubes, water tubes between machines;

3.

Lubricating oil, recirculation oil, gear box oil, recirculation cooling water;

4.

Safety equipments and non-standard safety items;

5. Testing material;

6.

Engineering service required at the buyer’s site.

Applications:

Floor deck is a lightweight decking system, for car pack construction, comprising steel profile, top-reinforced

by concrete. Floor deck roll forming machine is the essential manufacturer of its production.