HJ AUTOMATIC CONTROL TECHNOLOGY CO., LTD |

|

Verified Suppliers

|

|

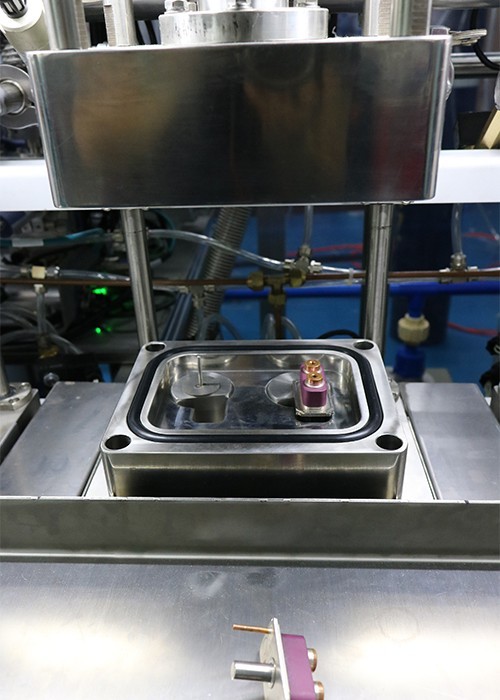

Vacuum Helium Leak Test System for Power Relays With 3 Vacuum Chambers

Basic Functions:

Operator inserts copper tube of the product into the fixture hole and presses the start button, the functions of closing the chamber, vacuuming the chamber, vacuuming the product, filling the product, vacuum leak detection, and venting the chamber can be automatically finished.

Special Sealing Fixture:

Adopts a special sealing structure design, which can solve the connection and sealing problem between the workpiece and the system. The sealing performance can reach leakage ≤1×10-9Pa.M3/s, which ensures that the helium gas detected during the leak detection process is possible from the workpiece. Leak Testing Equipment

Background Cleaning Technology:

HJ AUTO's patented helium background noise cleaning technology can effectively remove the helium background noise of the vacuum chamber system, provide a clean and stable reference background environment for the system, and avoid the system's radon background noise level to excessively affect the stability of the system operation, and improve the operating efficiency of the system.

Specification:

| Workpiece | Electric Automotive Power Relays (The surface of the product to be inspected needs to be cleaned and dried.) |

| Vacuum Chamber Type | Bell type. Leak Testing Equipment |

| Vacuum Chamber Size | 140*450*140mm |

| Quantity of Vacuum Chamber | 3 |

| Quantity of Fixture | 3 sets, 1 set per each vacuum chamber One to five products can be installed on 1 set of fixtures at a time, the vacant positions are plugged with plugs If only one work piece is installed in the chamber, the installation holes of the other four workpieces are plugged with plugs. The connection between the fixture and the workpiece is fast and automatic. The fixture needs to be replaced when the product is changed (the exchange of fixtures needs to be completed in 10 minutes) |

| Gas for Fine Leak Test | Helium |

| Gas Pressure for Fine Leak Test | <0.7MPa, adjustable |

| Helium Recovery | No (Optional) |

| Test Cycle | 90s/5pcs (3 vacuum chambers work linkage, each chamber contains 5 pcs, on average every 90 seconds to finish 5 chamber detections, including 20s loading & unloading time) |

| Rejection Rate | 1.0×10-9Pa.m3/sec |