HJ AUTOMATIC CONTROL TECHNOLOGY CO., LTD |

|

Verified Suppliers

|

|

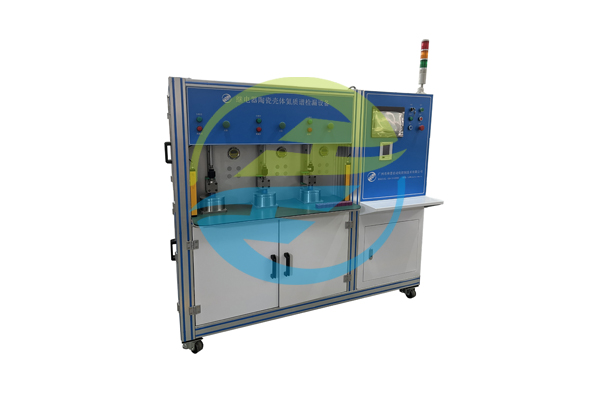

Ceramic Shell Helium Leak Detection System

Ceramic Shell Helium Leak Detection System Leak Rate 1.0*10-9Pa·m3/sec

Introduction of Ceramic Shell Helium Leak Detection System:

According to the basic principle of helium leak detection, using helium as a tracer gas, the system automatically and quickly detects the leakage of the workpiece. If there is a leak, the system will give an alarm.

Detection Process of Ceramic Shell Helium Leak Detection System:

1. The operator places the workpiece into the fixed fixture and presses the start button.

2. The vacuum box automatically closes and the fixture automatically seals.

3. The system automatically vacuums the vacuum box and workpiece.

4. The system automatically fills the product with helium.

5. The system automatically performs leak detection on the product.

6. If the test result is qualified:

a. The system automatically exhausts helium.

b. The system automatically opens the vacuum box door.

c. The qualified indicator light is on, and the operator unloads the product.

d. The operator installs the next product to be inspected and starts a new testing cycle.

7. If the test result is unqualified:

a. The system automatically exhausts helium.

b. Manually press the confirm button.

c. Automatic unboxing.

d. The unqualified indicator light is on, and the operator unloads the product.

e. The operator installs the next product to be inspected and starts a new testing cycle.

Feature of Ceramic Shell Helium Leak Detection System:

1. The equipment has three vacuum boxes that operate in linkage, requiring only one operator to operate the equipment.

2. The workpiece automatically completes the entire process in the vacuum box, which adopts a bell-shaped structure and can automatically open and close up and down. The operator only needs to load and unload materials, and the loading and unloading are simple and convenient.

3. The vacuum box fixture can install up to one workpiece at a time. If it is not necessary to install the workpiece, the corresponding workpiece installation hole can be blocked with a plug.

4. The helium detection adopts an imported leak detector, with a maximum leak detection accuracy of 5 * 10-13Pa · m3/s. The leak detection process can identify large and small leak workpieces, saving helium gas consumption.

5. The equipment is randomly provided with a simulated leak of 1.0E-9 Pa · m3/s, with a certificate issued by the national metrology institution for the leak.

6. The distance between the helium filled valve and the workpiece is short, the gas consumption is low, and the production cost is reduced.

7. The system is controlled by PLC. And display various information on a color touch screen.

8. Equipment operation safety, with safety protection and emergency stop, reset function.

9. The equipment design complies with ergonomic requirements.

Parameter of Ceramic Shell Helium Leak Detection System:

| Model | HJ122 |

| Tested workpiece | Ceramic shell |

| Number of vacuum boxes | 3 (only one product is tested per box) |

| Tracer gas | Helium gas |

| Helium pressure | 0.5MPa |

| Helium recovery | No recycling |

| Cycle time | 205 pieces/hour |

| Alarm leakage rate | 1.0*10-9Pa·m3/sec |