Mineral Water Blowing-Filling-Capping Machine Pure Water Filling

Bottling Machine

This series of Automatic PET Bottle Filling Line are applied to used in production of PET bottle-packing water ,such as mineral

water,pure water,drinking water and other non-carbonated beverage, it integrates bottle washing, filling and capping into one body of

this machine. It is very convenient to change bottle size by means

of advanced bottle conveying technology--bottleneck clamping &

bottle suspending technology.

Main Feature:

- This machine has a compact structure, perfect control system, easy

to operate and highly automated.

- The parts contact with product is made of quality SUS,

anti-corrosive, and easy to clean.

- By adopting high speed filling valve, the liquid level is precise

and no waste. That guarantees the demand of filling technology.

- The capping head adopts constant torque magnetic device to

guarantee capping quality and impact cap.

- This machine has a high efficient cap arranging system, perfect cap

feeding and protection device.

- Equipped with perfect clean management system to ensure the bottle

clean.

- Only by changing the star-wheel, can realize to fill the changed

bottle shape.

- The machine adopts perfect overload protective device can ensure

the operator and machine safe.

- This machine adopts adjustable frequency converter.

- The main electric components, frequency, photoelectric switch,

proximity switch, electric control valves all adopt imported

components, which can ensure the quality performance.

- The control system has many functions, such as control producing

speed, cap shortage detection, bottle block automatic stop and

production counting etc.

- The electric components and pneumatic components are all introduced

from world famous brand products.

Final Products

Bottled Water Filling Machine |

Application | Mineral water and other bottled water etc. |

Applied Containers | PET bottles with various capacities and shapes. |

Filling System | Mechanical valve or flow-meter valve. |

Capacity | 2000-24000BPH. |

Bottle Size | From 0.1 L to 1.5 L, 1 L |

Product's Scope | Blowing molding system, air compressor system, filling system ,

purification system, caps sterilization system, sterile air system,

filled bottle conveying system, labelling machine, carton/film

packing machine, palletizer, electric control, engineering design

and construction. |

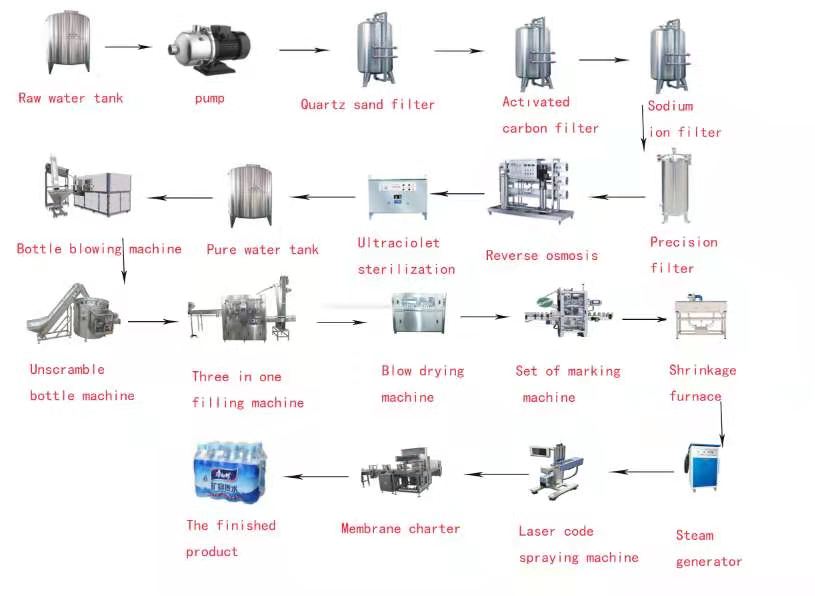

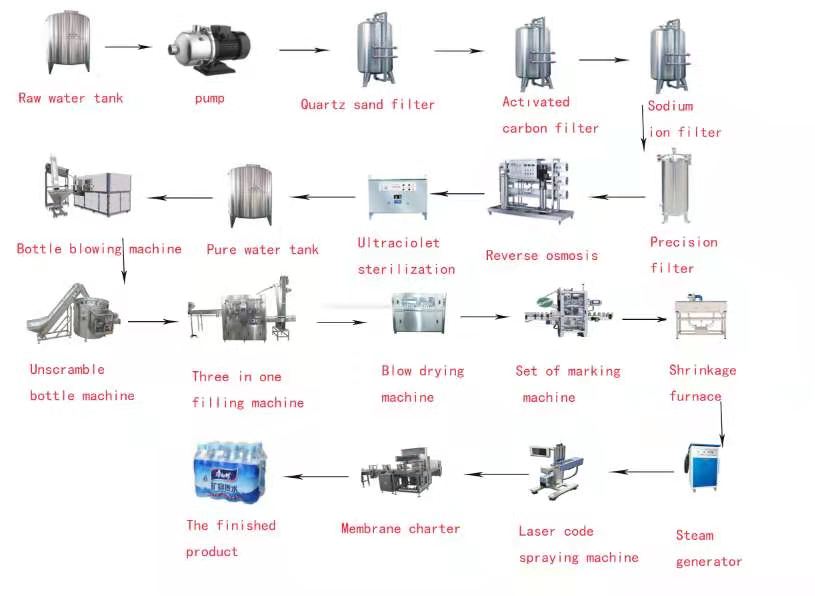

Water Treatment.

* Raw water tank + Raw water pump

* Silica sand filter + Active carbon filter + Sodium ion exchanger

+ Precision filter + Security filter

* Reverse Osmosis (one level)

* UV sterilizer

* Finished water tank + Pure water pump

Air Conveyor.

- Air conveyor is fixed on the floor, with fan installed on the

top.

- Air filter is positioned at every entrance of air fan, to prevent

dust blown into bottles.

- Bottles are held on the neck in the conveyor and transported into

filling machine by blowing power.

- All are made of stainless steel SUS 304 /316.

- Rack made by high quality carbon steel welded.

Full automatic blow molding machine is suitable for producing PET

plastic containers and bottles in all shapes. It is widely used to

produce the carbonated bottle, mineral water, pesticide bottle oil

bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

Optional Equipment :1)Heat shrink sleeve labeling machine

2)OPP Hot gule melt labeling machine

3)Self-adhesive labeling machine

Package Machine

The Machine is developed for mineral water,pop-top cans,glass

bottle,beer etc.combination packing with stable function,and the

packed articles tight and orderliness.This is a fully automatic

production line integrated with such processed as automatic

conveying,feeding,tube management,cutting shrinking and cooling

shaped-fixing flow.For large collectively counted case (box or

can)packing,it is preferred to encase with PE or PVC Shrinking film

before shrink package.

Bottle Blow Molding System

1.Water Bottle Series - 2000-24000bph on 500ml

2.Hot Fill Series - 1000-12000bph on 500ml

3.Large bottle series - 1000-5000bph on 5L

4.Extra Large bottle series-150bph on 20L

Filling System

1.5000-36000bph Bottle Water Production Line

2.5000-36000bph Carbonated Soft Drink Production Line

3.5000-36000bph Juice/Tea/Milk Beverage Production Line

4.3000-24000bph Oil/Viscous Liquid Production Line

5.1000-24000bph Glass Bottle Production Line

6.100-600CPM Can Filling Line

7.5000-36000bph Beverage Middle Temperature/Ultra-clean Production

Line

8.100-3000BPH 3/5 Gallon Barrel Water Production Line

9. 1000-3000bph water filling machine

10.3000-6000bph water filling machine

Processing System

1.1-100TPH Drinking Water Treatment System

2.1-30TPH Beverage Processing System

3.1-30TPH Beverage Sterilizer System

Post Packing System

1.5000-36000Shrink Sleeve / Hot Glue / Sticker Labeling Machine

2.5000-36000Secondary Packing Equipment