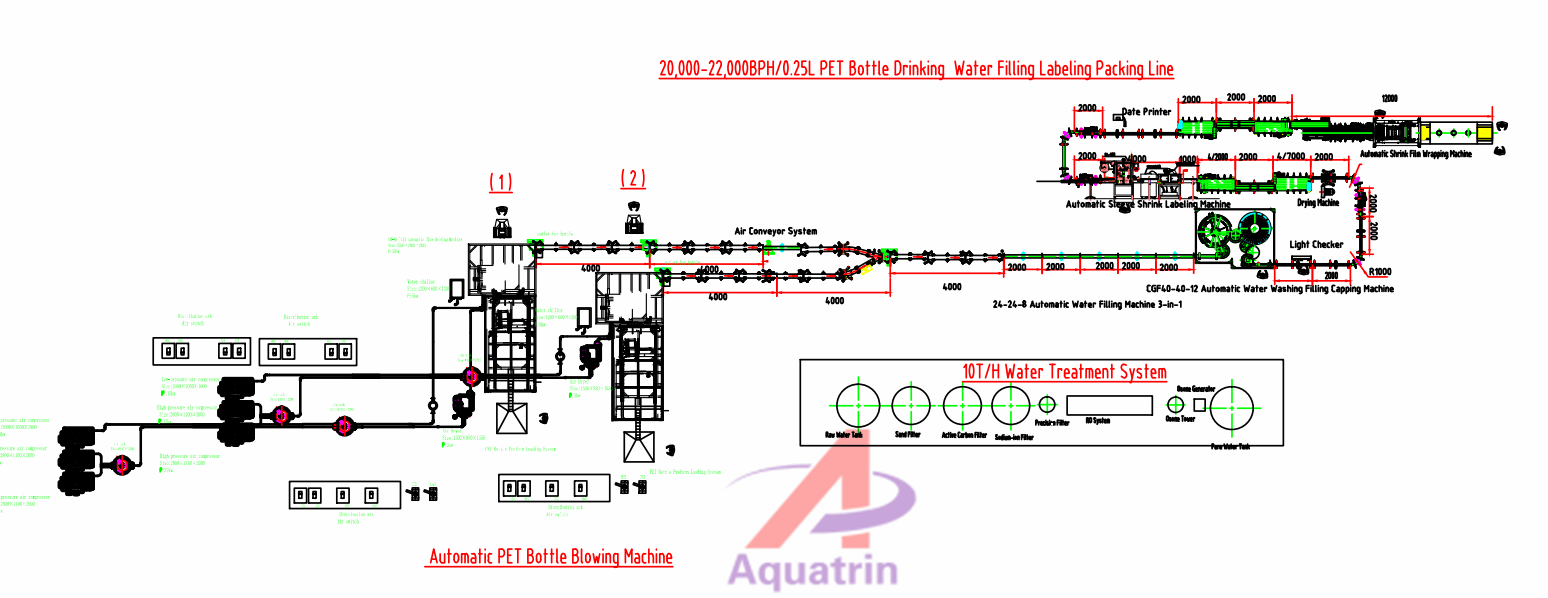

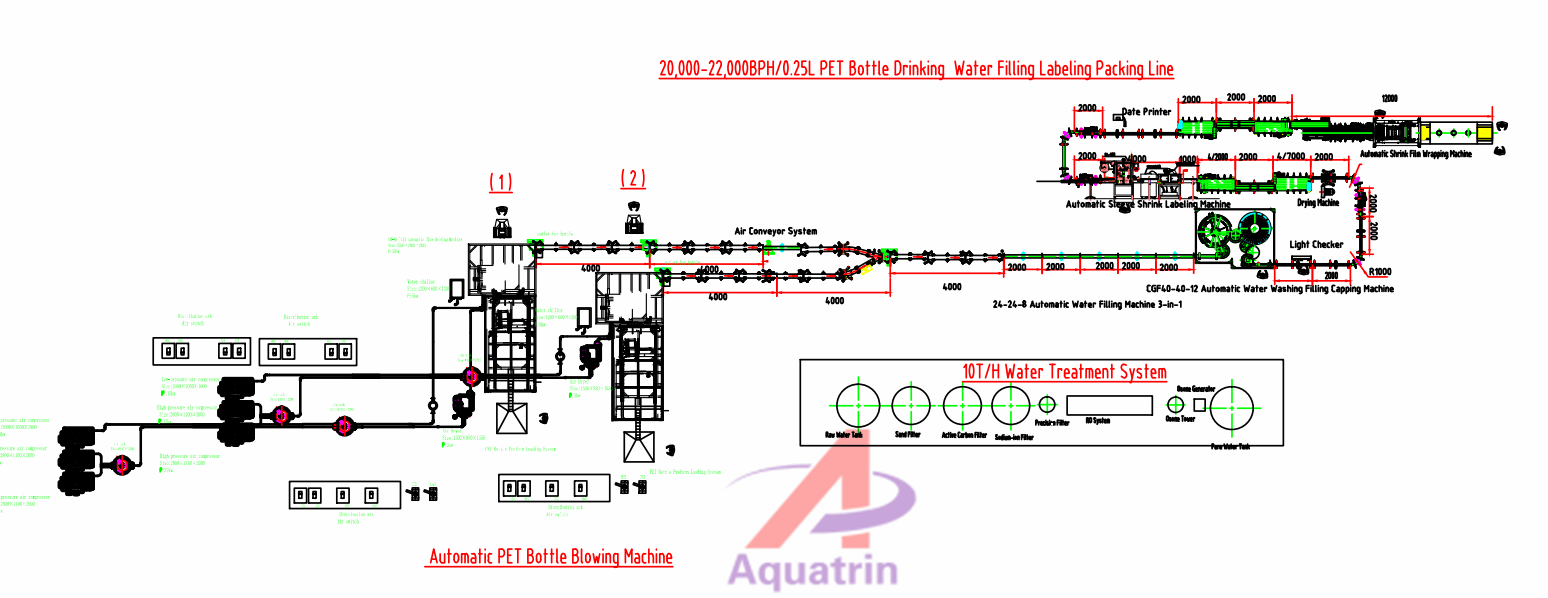

Drinking Water Filling Machine PET Bottled Still Water Filling

Plant Filling Line

Product Application

3-in-1 filling monoblock, combined with rinsing, filling and

capping. It is innovated and designed in the requirement of still

pure water and mineral water, on the bases of introducing,

digesting and absorbing advanced technology from Germany and Italy.

This CGF washing-filling-capping 3-in-1 unit: Beverage Machinery is

used to produce polyester bottled mineral water, purified water,

alcoholic beverage machinery and other non-gas beverage machinery.

The CGF washing-filling-capping 3-in-1 unit: Beverage Machinery can

finish all the process such as press bottle, filling and sealing,

it can reduce the materials and outsiders touch time, improve the

sanitary conditions, production capacity and economic efficiency.

02 - Washing Parts.

- Into bottle way is air conveyor direct connection with bottle

dial.

- All 304/316 stainless steel rinse heads, water spray style inject

design, more save water consumption and more clean.

- 304/316 Stainless steel Gripper with plastic pad, ensure minimal

bottle crash during washing.

- 304/316 stainless steel washing pump make the machine more

durable.

04 - Capping Parts.

- Place and capping system, electromagnetic capping heads, with

burden discharge function, make sure minimum bottle crash during

capping

- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.2%

MACHINE SPECIFICATION

| Model | CGF8-8-3 | CGF14-12-5 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-12 | CGF50-50-15 |

| Capacity(B/h) | 2000 | 5000 | 8000 | 12000 | 15000 | 18000 | 24000 |

| Floor Area | 300m2 | 400m2 | 600m2 | 1000m2 | 2000m2 | 2500m2 | 3500m2 |

| Total Power | 100KVA | 100KVA | 200KVA | 300KVA | 450KVA | 500KVA | 600KVA |

| Workers | 8 | 8 | 6 | 6 | 6 | 6 | 6 |

We suplly Free Factory Layout design

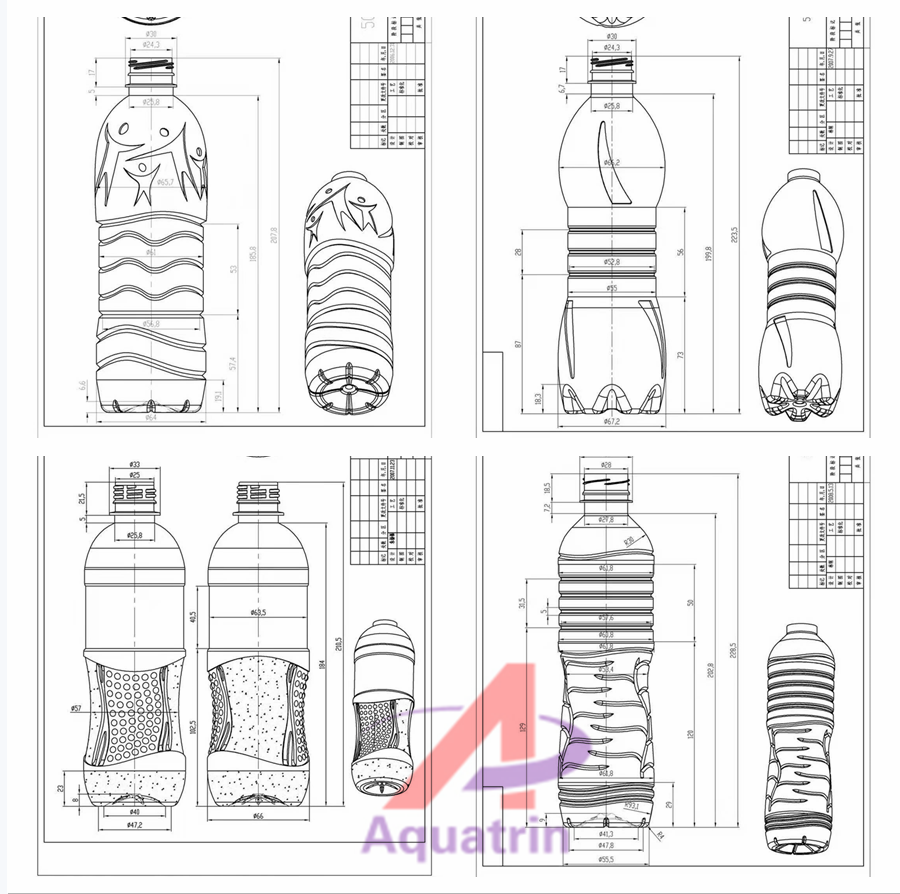

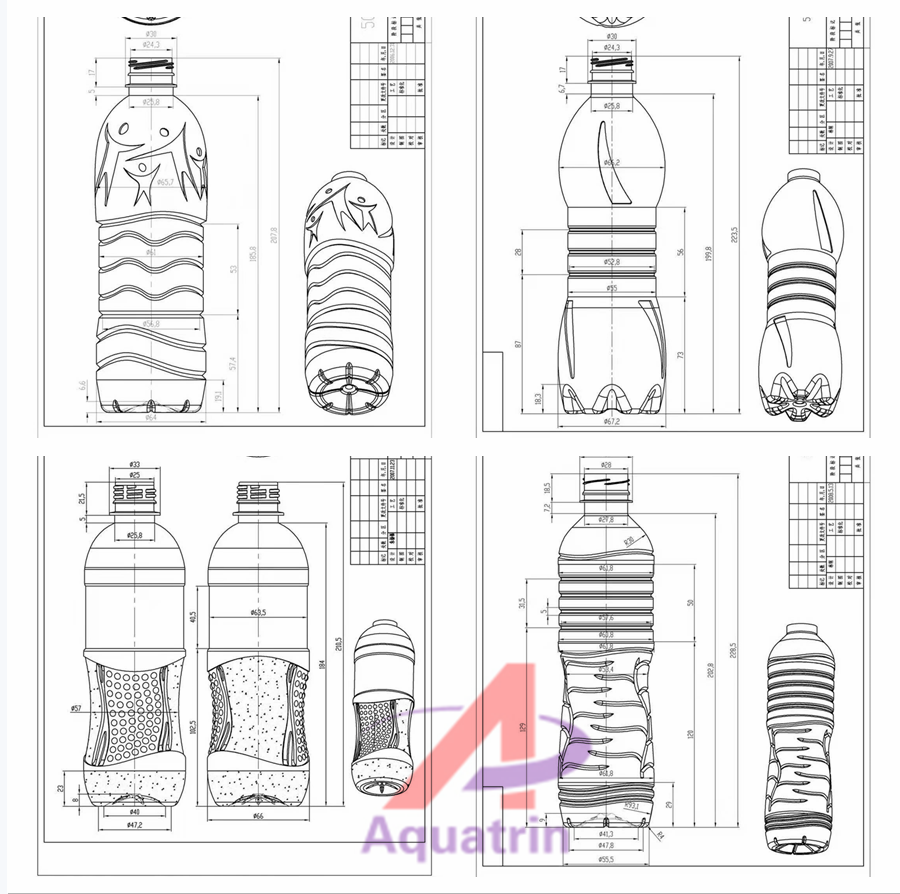

We suplly Free Bottle Shape design