Active Member

|

[China]

Address: 1708#, No. 1 building, Lane 2742, Pudong Avenue Road, Pudong, Shanghai

Contact name:Mrs. Lotus

Higee Machinery (Shanghai) Co.,Ltd |

|

Precision Olive Oil Filling Machine And Capping Machine With Labeling Machine

Olive oil filling machine and capping machine with labeling machine, detergent liquid filling machine for glass bottle

Olive oil filling machine features:

The machine is compact and reasonable in design, simple and

beautiful in appearance, and convenient in filling volume

adjustment. Suitable for making different viscosity agent and

cream. Multi head filling at the same time can increase or reduce

the number of filling heads as required. Quick cleaning, quick

adjustment, and stepless speed regulation of volume cylinder body

are suitable for filling different specifications and liquids. Once

the filling volume is adjusted, each volume cylinder can be

adjusted separately, with high accuracy and good consistency. The

imported speed reducer servo motor stepless speed control to fill

the piston cylinder is not only suitable for all kinds of water,

but also suitable for viscous liquids. The imported electromagnetic

clutch works with the electromagnetic brake to eliminate inertia

and high filling accuracy. The man-machine interface and PLC

communication, adjust the filling volume, debugging equipment or

replacement varieties only need to be set on the screen. Bottle

feeding, positioning, filling filling and discharging bottles are

automatically operated. The equipment will be automatically

protected when the bottle is not in place, the bottle is blocked or

the liquid outlet pipe is not inserted into the bottle. The use of

excellent quality components ensures its excellent quality and

durable and stable performance. The filling head can automatically

adjust the upper and lower adjustment convenience, convenient

maintenance, without any special tools. Humanized design, truly

adjust the convenience, no bottle, no filling, accurate loading. It

adopts the filling and filling system for preventing dripping and

drawing, the filling and lifting system for preventing high foaming

products, the positioning system and the liquid level control

system for ensuring the positioning of the bottle mouth.

(appearance can be customized according to customer requirements)

Technical parameters:

Canned capacity: 100-5000ML (custom-made)

Tank speed: 25-35 bottles / minutes (10 heads)

The precision of canning: < 0.3%

Power: 380V 60HZ

Air pressure: 4-6MPa

Shape size: 3000mm x 1500mm x 2200mm

Weight: 800kg

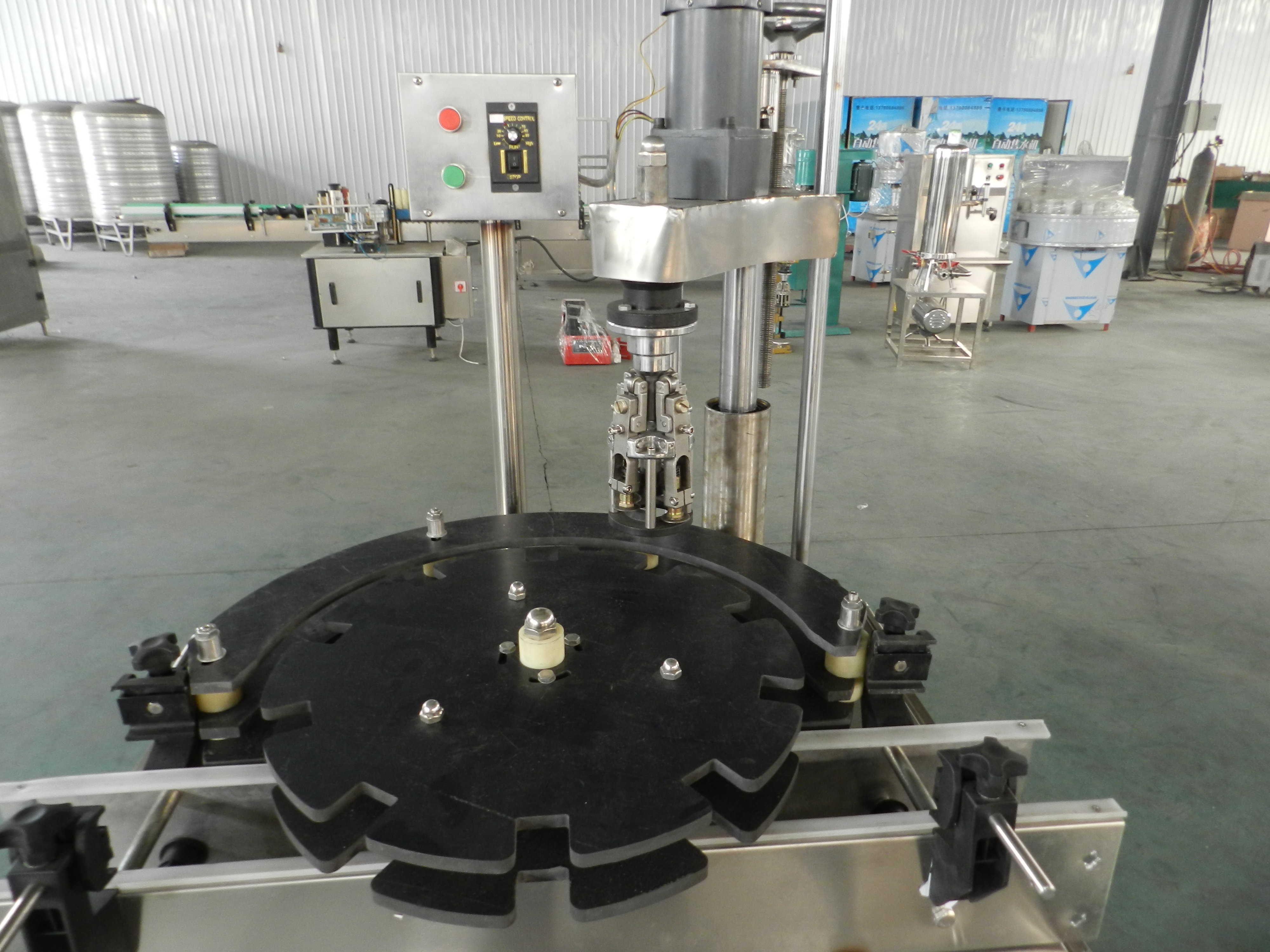

Our machine pictures :

Our service:

After sales service:

1.Installation & adjustment

After the equipment are arrived at the customer’s site, the

customer is responsible for unpacking and arranging the equipment

according to the placement drawing; and does under our

install-adjust technicians’ guidance. Costs of the staff are

decided at last.

2.Training

We are responsible for offering the technical training to user. The

training content includes the structure and maintenance of the

equipment, control and operation of the equipment. Through

training, users' technical staff can grasp and the skill of

operation and maintenance proficiently, and deal with the general

troubles in time. We will appoint qualified technical staff for the

guidance.

The buyer can send staff to our company for learning.

3.Quality assurance

We guarantee the goods offered are brand-new, not used, with latest

design and suitable material made, and we guarantee the

specification of the equipment is consonance with the contract.

We guarantee the line achieve product technical performance

indicators within 5 days after feeding operation through the

correct guidance of the installation and commissioning.

We are responsible for the fault and damage of the production line

caused by our design, technology, manufacture, installation,

adjustment and material defect etc. that all belong to our

responsibility.

The warranty period is 12 months after acceptance check of the

production line. If there is any different between the furnished

equipment in the customer’s factory and the equipment concerned in

the contract, the users have the right to pass the inspection book

to the legal department to claim for compensation to our company

within goods warranty period.

4.Warranty

Offer 12 months maintenance period to the problem that caused by

our design, manufacture and the material quality, and offer the

relevant parts and effective service for free for above reason. We

will offer a widely and favorable technical support, after service

all the time after guarantee period.