LeadTop Pharmaceutical Machinery Co., LTD |

|

Verified Suppliers

|

|

Automatic Packing Filling Sealing Machine is separating and packaging one combination, the machine quality is stable and reliable; The machine adopts double vibration cutting material packaging, above the weighing machine with vibration cutting, the other weighing bucket also install a vibration motor, the items in the discharge can follow the vibration, the following packaging Sealing machine also has a vibration with the installation, the material will also be when the vibration, the powder particles can be better products under the packaging, not easy to card material, so that packaging more smoothly.

Filling Sealing Machine for filter cotton paper, composite film, aluminum foil bags, non-woven fabrics, oil paper, heat sealing plastic bags and other heat-sealing packaging materials.

Application

This automatic liquid packing machine is suitable for automatic packaging of liquid of foods,medicine and chemicals,such as pesticide,shampoo,body foam bath lotion, facial cream, ingredient oil,fruit sauce,tomato ketchup and honey etc.

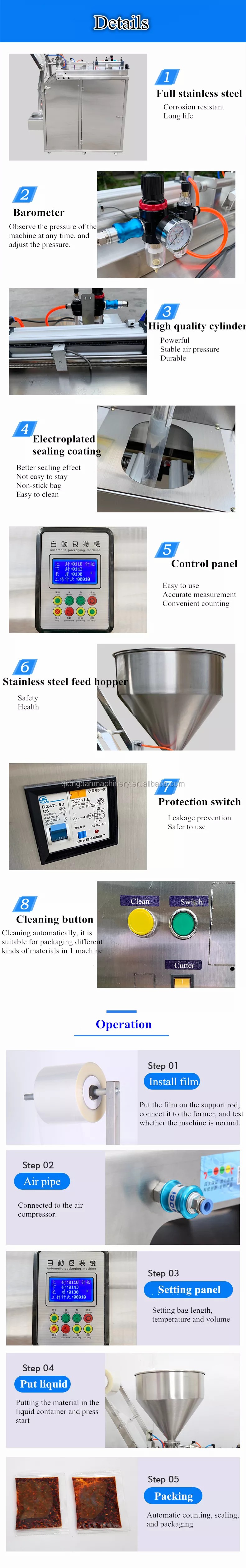

Features

1) Be able to weight, bag-making, filling, sealing, cutting,lot number automatically;

2) It has color control system which can get the complete trade mark design(photoelectricity control system);

3) The machine fix stepper motor controller,its advantage is precise,needless to adjust other parts;

4) Intelligent temperature control by temperature controller to make heat balance better.use bilingual display screen control system and stainless steel cabinet;

5) Fine packaging performance ,low noise ,clear sealing texture and strong sealing performance;

6)With safe plastic box on rotating blade to avoid hurting operator's hands;

7) Need to change new temperature controller,blade& pressing mode only after 3 years continuous operation,2 shifts a day and other parts is still good and safe freely);

8)With printer (to be able to code the date and batch number) and rotating blade(be able to adjust the length of bag and shape of bag notch edge packing.