Anhui Aoxuan Heavy Industry Machine Co., Ltd. |

|

Verified Suppliers

|

|

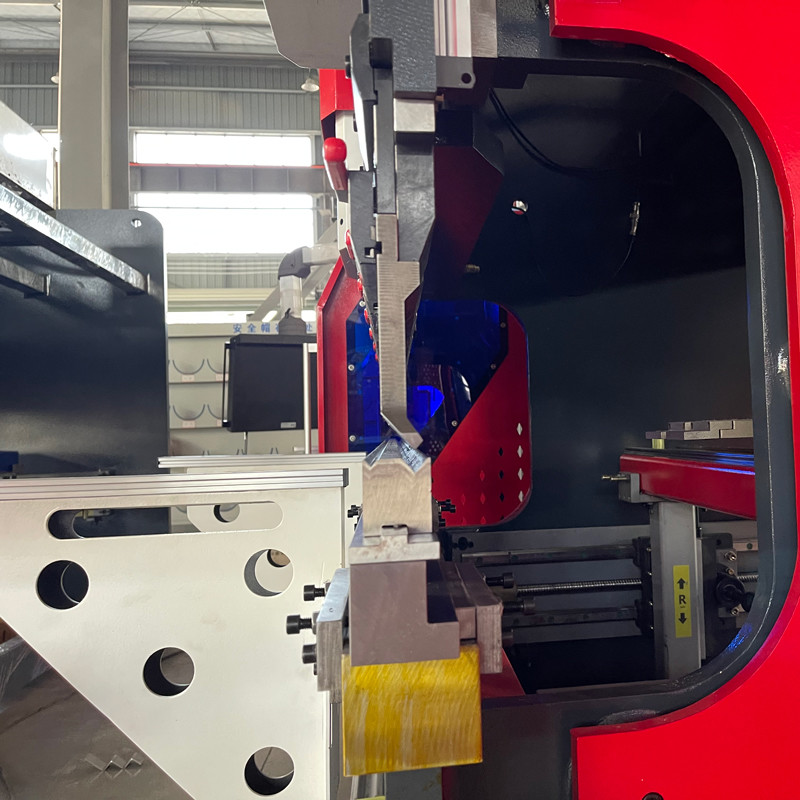

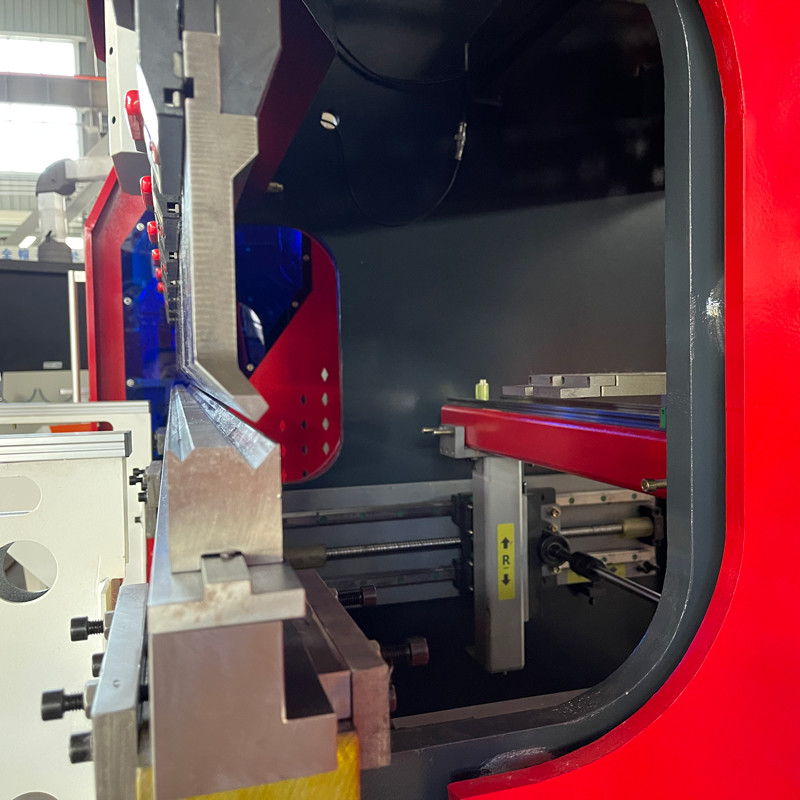

Hydraulic CNC Press Brake is a type of press bending machine that is equipped with a CNC controller. It is powered by a hydraulic pressure system and has a maximum bending force of 1000kn, making it ideal for bending metal sheets and plates of varying thickness. It has an overall dimension of 2605x1740x2400mm and a HK58T CNC controller for precise and accurate control of the bending process. This makes it ideal for producing high quality and accurate products. This reliable and powerful hydraulic press brake machine is suitable for a wide range of applications in various industries, including automotive, aerospace, construction, energy and engineering.

| Parameter | Value |

|---|---|

| Controller | HK58T |

| Motor Power | 7.5kw |

| Max. Bending Force | 1000kn |

| Maximum open height | 395mm |

| Distance between housings | 2050mm |

| Back Gauge Accuracy | ±0.01mm |

| Type | CNC Press Brake |

| Overall Dimension | 2605x1740x2400mm |

| Pressure | Hydraulic |

15.6-inch full-color touch screen

Simple and easy to understand operation interface

1. Support angle programming and depth programming switching

2. Support mold library product library settings

3. The opening height can be freely set for each working step.

4. The shifting point position can be freely controlled

5. Standard Y1, Y2, R-axis multi-axis expansion

6. Support mechanical compensation workbench control

7. Support large arc automatic generation program

8. Supports top dead center, bottom dead center, foot release,

delay and other step changing options, effectively improving

processing efficiency

9. Support electromagnet simple bridge

10. Supports fully automatic pneumatic supporting bridge function

11. Support automatic bending, realize unmanned bending control,

support up to 25 steps of automatic bending

12. Support valve group configuration functions, fast down, slow

down, return, unloading action and valve action time control

13. 200 product libraries with 25 working steps, each product

library name can be customized in Chinese and English, and the

large arc supports 99 working steps.

Hydraulic CNC Press Brake provides comprehensive technical support and service for customers. Technical staff are available to answer questions and provide assistance regarding product installation, operation, maintenance and repair. Customers can also contact technical team to find solutions to their specific application needs. Our service team provides customer service, technical consultation and after sales service.

Hydraulic CNC Press Brake offers 24-hour online support. Customers can contact our online customer service team for any inquiries or questions. The customer service team is also available to help customers with product installation, operation, maintenance and repair.

In addition, Hydraulic CNC Press Brake offers free training to help customers understand the product and its operation. The training includes product introduction, product operation and maintenance, software operation and troubleshooting. Customers can also get help from our technical team to solve any problems with the product.

Hydraulic CNC Press Brake is committed to providing the best customer service and technical support. We are always ready to help customers with any issues they may have.

The Hydraulic CNC Press Brake is packaged with extra care and attention to ensure that the product is safe and secure during its entire shipping journey. The machine is first wrapped in a thick plastic material and then placed in a box made from corrugated cardboard for extra protection. The box is then sealed using heavy-duty tape to prevent it from opening during transit. The box is placed in a shipping crate with foam padding and secured with straps and metal bands. The shipping crate is then placed on a pallet for easy transportation.

1. Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of

Analysis/Conformance: Insurance: Origin, and other export documents

where required.

2. What is the average lead time?

For samples the lead time is about 7 days. For mass production the

lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when (1) we have received your

deposit and (2) we have your final approval for your products. If

our lead times do not work with your deadline, please go over your

requirements with your sale. In all cases we will try to

accommodate your needs. In most cases we are able to do so.

3. What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or

Alipay:30% deposit in advance, 70% balance before shipment.

4. What is the product warranty?

The warranty period is 13 months after the bill of lading date. We

warranty our materials and workmanship. Our commitment is to your

satisfaction with our products. In warranty or not, it is the

culture of our company to address and resolve all customer issues

to everyone's satisfaction.

5. Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use

specialized hazard packing for dangerous goods and validated cold

storage shippers for temperature sensitive items. Specialist

packaging and non-standard packing requirements may incur an

additional charge.

6. How about the shipping fees?

The shipping cost depends on the way you choose to get the goods.

Express is normally the quickest but also most expensive way. By

seafreight is the best solution for big amounts. Exactly freight

rates we can only give you if we know the details of amount, weight

and way. Please contact us for further information.

7.Are you a manufacturer? Can we come and visit your factory?

Yes, we are manufacturer. You are welcome to visit the factory, and

we will introduce the products you are interested in in detail on

the spot.