Anhui Aoxuan Heavy Industry Machine Co., Ltd. |

|

Verified Suppliers

|

|

Press brake is a machine capable of bending plates, which has a

wide range of applications and uses:

1. In the electric power industry, the shearing machine can cut the

plates into different sizes, and then process them again through

the Press brake, such as computer cases, electrical cabinets,

refrigerator air-conditioning shells, etc. are all made in this

way;

2. In the decoration industry, high-speed CNC shearing machines are

widely used, generally used in conjunction with CNCPress brake, to

complete the production of stainless steel plates, doors and

windows, and decoration in some special places;

3. In the automobile and shipbuilding industry, large-scale CNC

hydraulic shearing machines are generally used, mainly to complete

the shearing work of the plate, and then perform secondary

processing, such as welding, bending, etc.;

4. In the kitchen and catering industry, stainless steel kitchen

utensils of various varieties and specifications are then subjected

to secondary processing, such as welding, bending, etc.;

5. In the aerospace industry, high precision is generally required,

and high-precision CNC shearing machines and Press brake can be

selected, which are accurate and efficient;

6. In the wind power communication industry, wind power generation

poles, road light poles, communication tower poles, traffic light

poles, traffic signal poles, monitoring poles, etc. are bent;

· New EU streamlined design

· The frame of the bending machine adopts integrated welding and

tempering to eliminate internal stress

· The frame of the bending machine adopts shot blasting to remove

rust and is sprayed with anti-rust treatment

· The frame is formed once by the imported CNC three-dimensional

machining center, which ensures the parallelism and

perpendicularity of each mounting surface.

· The controller can control the Y1 and Y2 axes (Y1 controls the

left cylinder and Y2 controls the right cylinder) to ensure the

synchronous movement of the ram

· Waiting for quiet speed, fast speed reduction (about 25

decibels), low pressure return noise (the pressure of hydraulic

system is controlled by the servo main motor in closed-loop)

· The main oil pump does not work under the servo main motor drive,

and the energy consumption is 60% lower than that of the general

CNC bending machine

· Stable oil temperature, prolonging the service life of each

component of the hydraulic system

· More technological innovations to ensure bending quality,

powerful functions and easy operation

· The bending machine adopts the latest high-frequency hydraulic

control technology, which is faster, more efficient and more stable

· The best parameter ratio, the best core material configuration,

stable performance, more convenient operation, can realize the

bending of various shapes of complex workpiece.

Technical parameters:

| Model | Pressure | Worktable length | Distance between columns | Depth of throat | Stroke | Max height between worktable and ram | Main motor | Weight | Dimension (LxWxH) |

| Units | kn | mm | mm | mm | mm | mm | kw | mm | mm |

| WC67Y/K-40/2500 | 400 | 2500 | 1925 | 220 | 80 | 300 | 4 | 3000 | 2650x1100x1950 |

| WC67Y/K-50/2500 | 500 | 2500 | 2015 | 220 | 100 | 340 | 4 | 3750 | 2650x1250x2100 |

| WC67Y/K-63/2500 | 630 | 2500 | 2015 | 250 | 100 | 340 | 5.5 | 4300 | 2650x1300x2200 |

| WC67Y/K-80/2500 | 800 | 2500 | 2010 | 250 | 120 | 380 | 5.5 | 5200 | 2560x1350x2250 |

| WC67Y/K-80/3200 | 800 | 3200 | 2510 | 250 | 120 | 380 | 5.5 | 6000 | 3260x1350x2280 |

| WC67Y/K-100/2500 | 1000 | 2500 | 2050 | 320 | 150 | 420 | 7.5 | 6700 | 2550x1360x2270 |

| WC67Y/K-100/3200 | 1000 | 3200 | 2550 | 320 | 150 | 420 | 7.5 | 7200 | 3260x1365x2520 |

| WC67Y/K-100/4000 | 1000 | 4000 | 3050 | 320 | 150 | 420 | 7.5 | 8500 | 4060x1365x2720 |

| WC67Y/K-125/3200 | 1250 | 3200 | 2550 | 320 | 150 | 420 | 7.5 | 7800 | 3260x1465x2600 |

| WC67Y/K-125/4000 | 1250 | 4000 | 3050 | 320 | 150 | 420 | 7.5 | 9000 | 4060x1460x2800 |

| WC67Y/K-160/3200 | 1600 | 3200 | 2590 | 320 | 200 | 475 | 11 | 10500 | 3260x1580x2775 |

| WC67Y/K-160/4000 | 1600 | 4000 | 3040 | 320 | 200 | 475 | 11 | 12500 | 4060x1580x2925 |

| WC67Y/K-160/6000 | 1600 | 6000 | 4800 | 320 | 200 | 480 | 11 | 19500 | 6060x1580x3480 |

| WC67Y/K-200/3200 | 2000 | 3200 | 2580 | 320 | 200 | 475 | 18.5 | 13200 | 3260x1650x2800 |

| WC67Y/K-250/4000 | 2500 | 4000 | 3130 | 400 | 250 | 530 | 18.5 | 19000 | 4060x1840x3150 |

| WC67Y/K-250/5000 | 2500 | 5000 | 3930 | 400 | 250 | 530 | 18.5 | 24000 | 5060x1840x3450 |

| WC67Y/K-300/3200 | 3000 | 3200 | 2530 | 400 | 250 | 580 | 18.5 | 18000 | 3300x2100x2980 |

| WC67Y/K-300/4000 | 3000 | 4000 | 3200 | 400 | 250 | 580 | 18.5 | 22000 | 4060x2040x3330 |

| WC67Y/K-400/4000 | 4000 | 4000 | 3180 | 400 | 320 | 630 | 30 | 30000 | 4060x2220x3630 |

| WC67Y/K-400/6000 | 4000 | 6000 | 4700 | 400 | 320 | 630 | 30 | 45000 | 60602x2203x980 |

| WC67Y/K-500/6000 | 5000 | 6000 | 4600 | 500 | 320 | 70 | 30 | 55000 | 6080x2760x4000 |

| WC67Y/K-800/6000 | 8000 | 6000 | 4600 | 500 | 400 | 900 | 37 | 72000 | 6100x3250x4300 |

Customization:

Press brake:160T 3200 mm

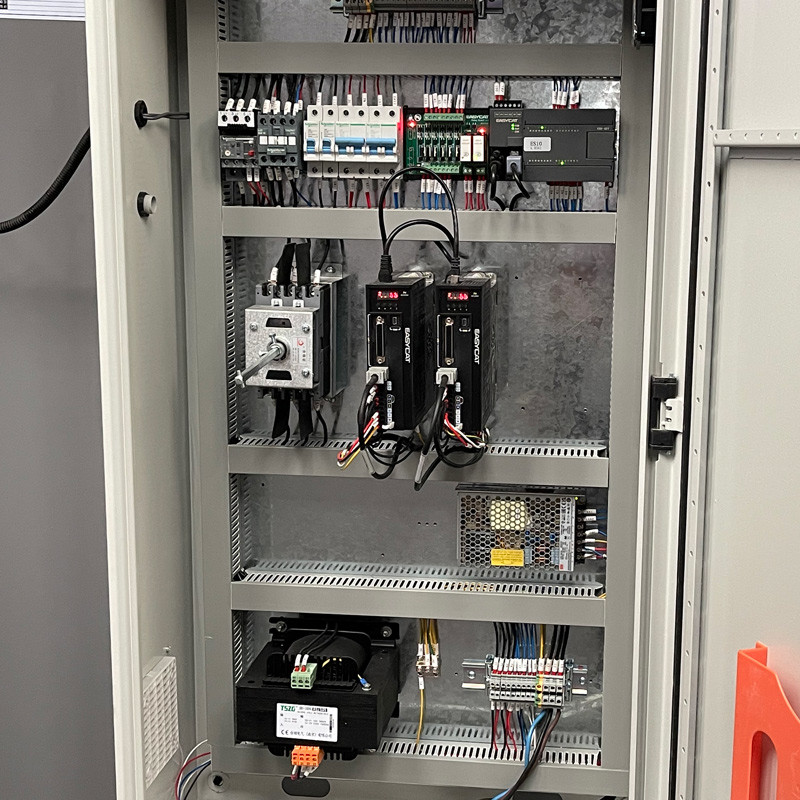

Controller : TP10S touch screen

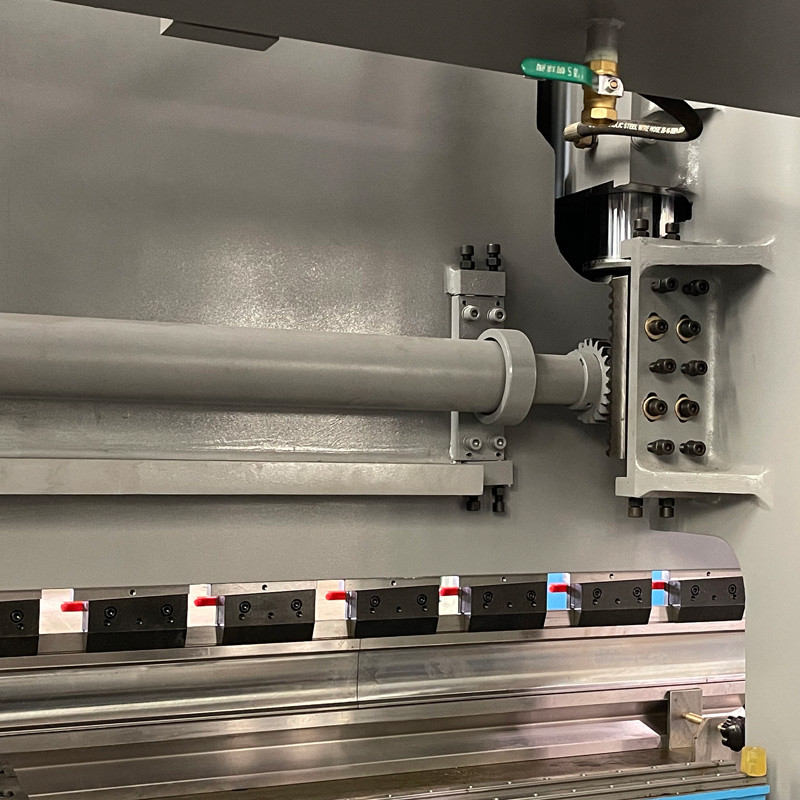

Fast clamp

Servo Motor: 2 sets

Ball screw & linear guide:HIWIN

Hydraulic valve:Rexroth,Germany

Tubing connector:EMB,Germany

Main Motor:German Siemens

Electrics:Schneider ,France

Hydraulic Pump:SUNNY,USA

Foot switch:Karcon,South Korea

CNC Stop finger with linear guide

Plate Support Arm

Hydraulic & Electrical overload protection

Protection facility :

-laser protection(Optional)

-Light screen protection(Optional)

Compensation device(Optional)

Rear guardrail(Optional)

Side guardrail

Pre-sales.

* Project design, performance introduction, technical agreement,

contract signing, packaging

* Inquiry and consulting support.

* Sample testing support.

In-sales.

* We will provide you with the latest progress in the product

assembly, packaging and transportation.

After-sale.

* We will provide free accessories for the damage to non - human

parts.

* Training how to install the machine, training how to use the

machine with video and so on

* And our technical staff can go abroad to provide technical

guidance.

1. Before packaged, the machines will be tested strictly to

guarantee the stability and high accuracy.

2. After tested, the machines will be wrapped with plastic sheet ,

3,a,Small size : carefully packed in wooden cases ;

b,Big size: machine will be securely wired into the container by

steel wire.

Packing Detail:

☂ Each Press Brake with plastic film package first, then placed in

a wooden case, wooden case with a foam filling.

✈ We loaded the truck with heavy trucks for loading the cargo to

the harbor terminal.At the dock we pack the goods in containers and

ship them abroad.

Delivery Detail :

☀ Shipped in 30 days after payment.

Q1: What is the Brand Name of the Hydraulic CNC Press Brake?

A1: The Brand Name of the Hydraulic CNC Press Brake is AOXUANZG.

Q2: What is the Model Number of the Hydraulic CNC Press Brake?

A2: The Model Number of the Hydraulic CNC Press Brake is WE67K-160T3200MM.

Q3: Where is the Hydraulic CNC Press Brake manufactured?

A3: The Hydraulic CNC Press Brake is manufactured in China.

Q4: What certifications does the Hydraulic CNC Press Brake have?

A4: The Hydraulic CNC Press Brake has CE and ISO certifications.

Q5: What is the minimum order quantity for the Hydraulic CNC Press Brake?

A5: The minimum order quantity for the Hydraulic CNC Press Brake is 1.