Anhui Aoxuan Heavy Industry Machine Co., Ltd. |

|

Verified Suppliers

|

|

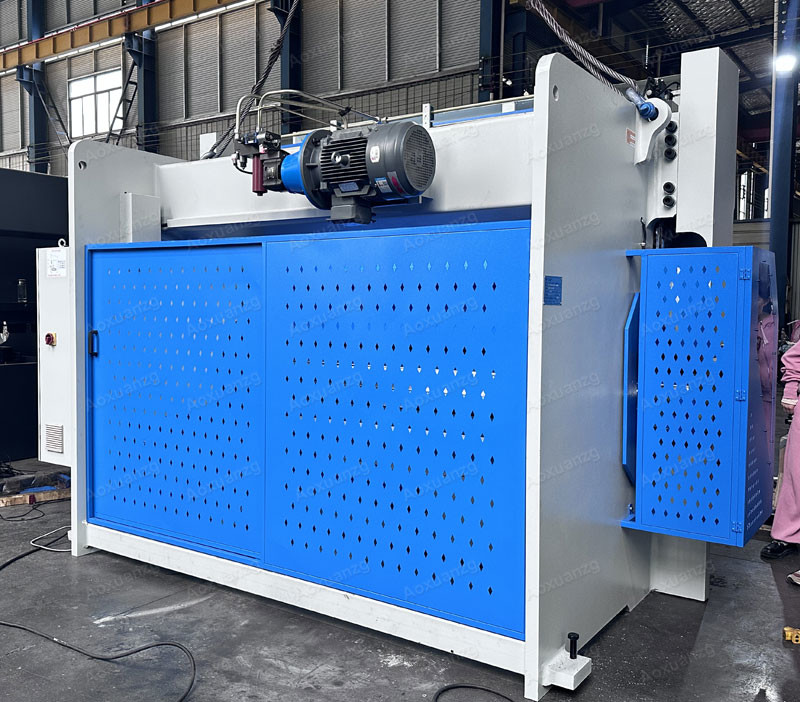

CNC ELECTRO-HYDRAULIC SYNCHRONOUS CNC PRESS BRAKE

CNC series of press brakes has been designed and crafted with an

ethos of heavy duty quality. The range also features the multi-axis

CNC controller, delivering the ability to handle complex,

multi-bend operations quickly and easily. Touch screen control is

quick and easy thanks to the user-friendly interface. There is also

the option of preparing the production off line on a PC with the

software provided, enabling feasibility checks prior to production

Optional Controller

The control panel you choose can have a real impact on your

productivity. To ensure you get the most out of your Press Brake,

the best decisions are always guided by your industry, your product

and even the things you hope to undertake in the future. We have

DA52S, DA53T, DA58T, DA66T, DA69T, S630, S640, Cybtouch8,

Cybtouch12 and other cnc controller.

1. Totally EU streamlined design. Monobloc by welding robots &

apparatus and stress relief process by annealing treatment.

2. Hydraulic top-drive, steadiness and reliability, mechanical

stop, steel torsion bar to maintain synchronization, high

precision.

3. Adopt integrated hydraulic system, more reliable and easy for

maintenance. and the hydraulic system from Bosch Rexroth, Germany.

4. Travel limit protection, full machine guarding with safety

interlocker.

5. Mechanical synchronous mechanism and the complex compensation

are designed so as to raise the workpieces precision.

6. The stroke and distance of the back gauge is adjusted by the

motor.

7. Inch, single mode being designed for the machine and reversing

and maintain time can be controlled by the time relays

8. Safe fence and the electric interlocker have been designed for

the machine to ensure the operation safety.

9. Standard punches and dies. Front arm material support. Foot

pedal with emergency stop.

10. Control system: Estun NC E21, CNC DELEM DA41, DA52, DA66T.

Press brake is a machine capable of bending plates, which has a

wide range of applications and uses:

1. In the electric power industry, the shearing machine can cut the

plates into different sizes, and then process them again through

the Press brake, such as computer cases, electrical cabinets,

refrigerator air-conditioning shells, etc. are all made in this

way;

2. In the decoration industry, high-speed CNC shearing machines are

widely used, generally used in conjunction with CNCPress brake, to

complete the production of stainless steel plates, doors and

windows, and decoration in some special places;

3. In the automobile and shipbuilding industry, large-scale CNC

hydraulic shearing machines are generally used, mainly to complete

the shearing work of the plate, and then perform secondary

processing, such as welding, bending, etc.;

4. In the kitchen and catering industry, stainless steel kitchen

utensils of various varieties and specifications are then subjected

to secondary processing, such as welding, bending, etc.;

5. In the aerospace industry, high precision is generally required,

and high-precision CNC shearing machines and Press brake can be

selected, which are accurate and efficient;

6. In the wind power communication industry, wind power generation

poles, road light poles, communication tower poles, traffic light

poles, traffic signal poles, monitoring poles, etc. are bent;

| Model | Pressure | Worktable length | Distance between columns | Depth of throat | Stroke | Max height between worktable and ram | Main motor | Weight | Dimension (LxWxH) |

| Units | kn | mm | mm | mm | mm | mm | kw | mm | mm |

| WC67Y/K-40/2500 | 400 | 2500 | 1925 | 220 | 80 | 300 | 4 | 3000 | 2650x1100x1950 |

| WC67Y/K-50/2500 | 500 | 2500 | 2015 | 220 | 100 | 340 | 4 | 3750 | 2650x1250x2100 |

| WC67Y/K-63/2500 | 630 | 2500 | 2015 | 250 | 100 | 340 | 5.5 | 4300 | 2650x1300x2200 |

| WC67Y/K-80/2500 | 800 | 2500 | 2010 | 250 | 120 | 380 | 5.5 | 5200 | 2560x1350x2250 |

| WC67Y/K-80/3200 | 800 | 3200 | 2510 | 250 | 120 | 380 | 5.5 | 6000 | 3260x1350x2280 |

| WC67Y/K-100/2500 | 1000 | 2500 | 2050 | 320 | 150 | 420 | 7.5 | 6700 | 2550x1360x2270 |

| WC67Y/K-100/3200 | 1000 | 3200 | 2550 | 320 | 150 | 420 | 7.5 | 7200 | 3260x1365x2520 |

| WC67Y/K-100/4000 | 1000 | 4000 | 3050 | 320 | 150 | 420 | 7.5 | 8500 | 4060x1365x2720 |

| WC67Y/K-125/3200 | 1250 | 3200 | 2550 | 320 | 150 | 420 | 7.5 | 7800 | 3260x1465x2600 |

| WC67Y/K-125/4000 | 1250 | 4000 | 3050 | 320 | 150 | 420 | 7.5 | 9000 | 4060x1460x2800 |

| WC67Y/K-160/3200 | 1600 | 3200 | 2590 | 320 | 200 | 475 | 11 | 10500 | 3260x1580x2775 |

| WC67Y/K-160/4000 | 1600 | 4000 | 3040 | 320 | 200 | 475 | 11 | 12500 | 4060x1580x2925 |

| WC67Y/K-160/6000 | 1600 | 6000 | 4800 | 320 | 200 | 480 | 11 | 19500 | 6060x1580x3480 |

| WC67Y/K-200/3200 | 2000 | 3200 | 2580 | 320 | 200 | 475 | 18.5 | 13200 | 3260x1650x2800 |

| WC67Y/K-250/4000 | 2500 | 4000 | 3130 | 400 | 250 | 530 | 18.5 | 19000 | 4060x1840x3150 |

| WC67Y/K-250/5000 | 2500 | 5000 | 3930 | 400 | 250 | 530 | 18.5 | 24000 | 5060x1840x3450 |

| WC67Y/K-300/3200 | 3000 | 3200 | 2530 | 400 | 250 | 580 | 18.5 | 18000 | 3300x2100x2980 |

| WC67Y/K-300/4000 | 3000 | 4000 | 3200 | 400 | 250 | 580 | 18.5 | 22000 | 4060x2040x3330 |

| WC67Y/K-400/4000 | 4000 | 4000 | 3180 | 400 | 320 | 630 | 30 | 30000 | 4060x2220x3630 |

| WC67Y/K-400/6000 | 4000 | 6000 | 4700 | 400 | 320 | 630 | 30 | 45000 | 60602x2203x980 |

| WC67Y/K-500/6000 | 5000 | 6000 | 4600 | 500 | 320 | 70 | 30 | 55000 | 6080x2760x4000 |

| WC67Y/K-800/6000 | 8000 | 6000 | 4600 | 500 | 400 | 900 | 37 | 72000 | 6100x3250x4300 |

Our Hydraulic CNC Press Brake offers technical support and services to ensure that your CNC Press Brake performs at its best.

Our experienced technicians are here to provide assistance on the operation and maintenance of your Hydraulic CNC Press Brake. This includes providing support on diagnosing and troubleshooting any potential issues, as well as providing guidance on how to get the most out of the machine. Additionally, our technicians can provide training on the safe and proper use of the machine.

Our technical support and service team is available 24/7 to assist you with any questions or concerns you may have about the Hydraulic CNC Press Brake. We strive to provide the best customer service and support to ensure total satisfaction with your purchase.

Packaging and Shipping for Hydraulic CNC Press Brake:

The Hydraulic CNC Press Brake is packaged in a wooden crate and must be handled with care during the shipping process. The crate is made of strong and durable wood for protection of the machine during transportation. It is also equipped with metal corner guards to further secure the machine from any possible damages that may occur during transit.

The crate is then sealed and secured with steel straps for extra security. The package is then shipped via a reputable shipping company, ensuring a safe and timely delivery to the destination.